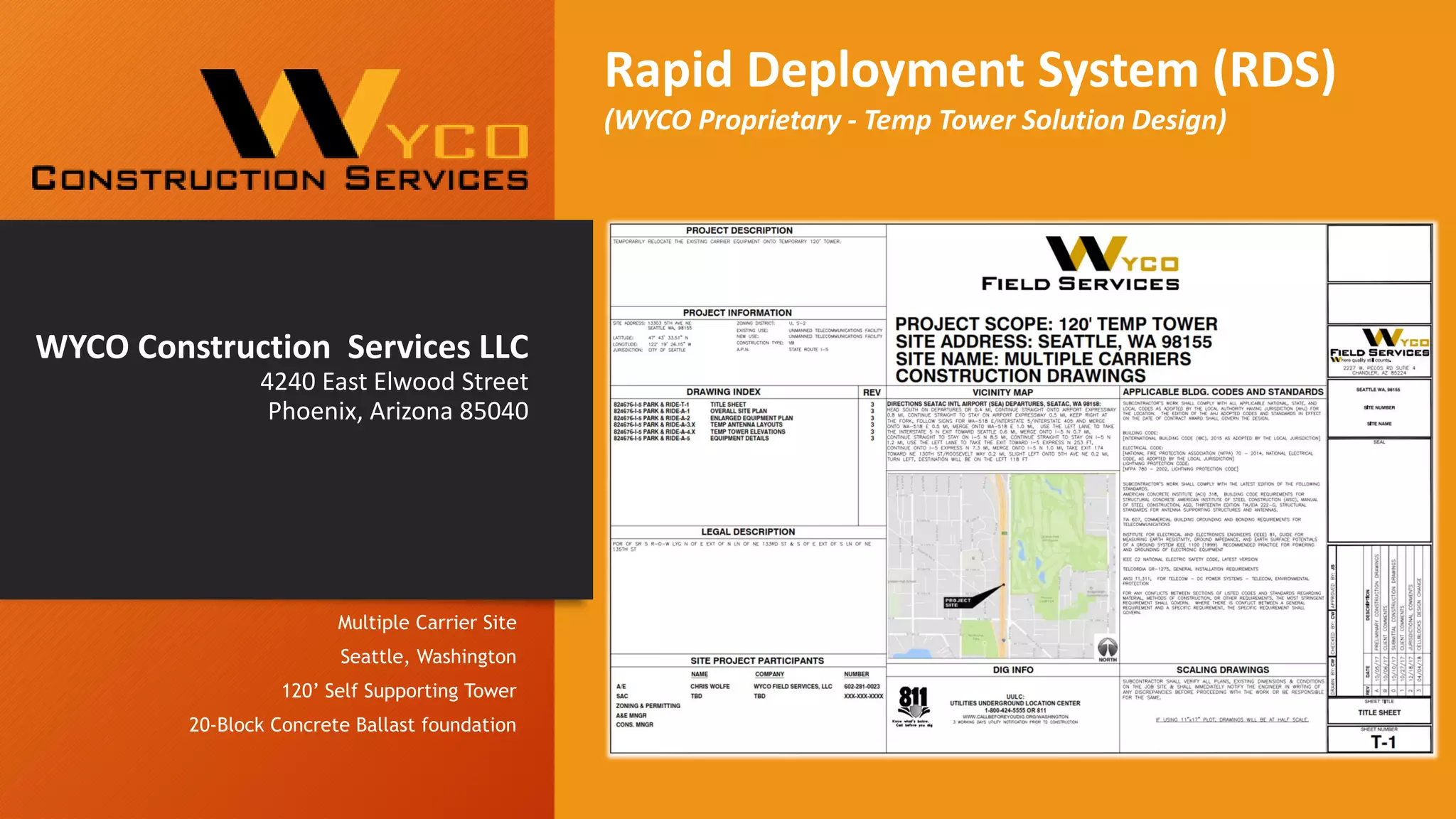

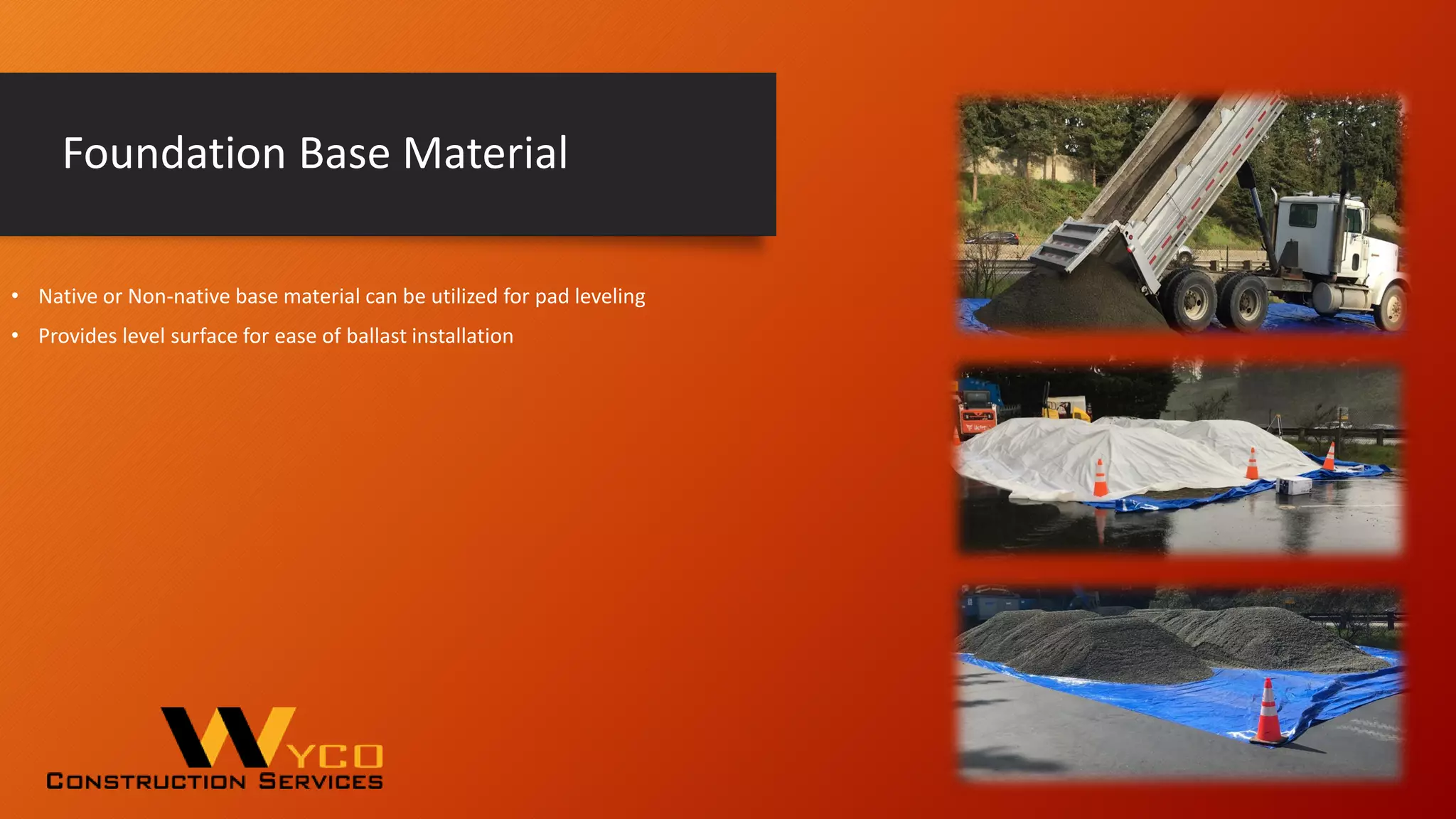

This document summarizes a project by WYCO Construction Services to install a temporary 120-foot self-supporting tower using a Rapid Deployment System (RDS) at a site in Seattle, Washington. The tower was needed to allow wireless carriers to remain operational while an existing structure was modified. The RDS design allowed for rapid construction in just three days and later dismantling with no ground disturbance. It provided a temporary wireless coverage solution using a proprietary ballast foundation system until modifications to the original tower were complete.