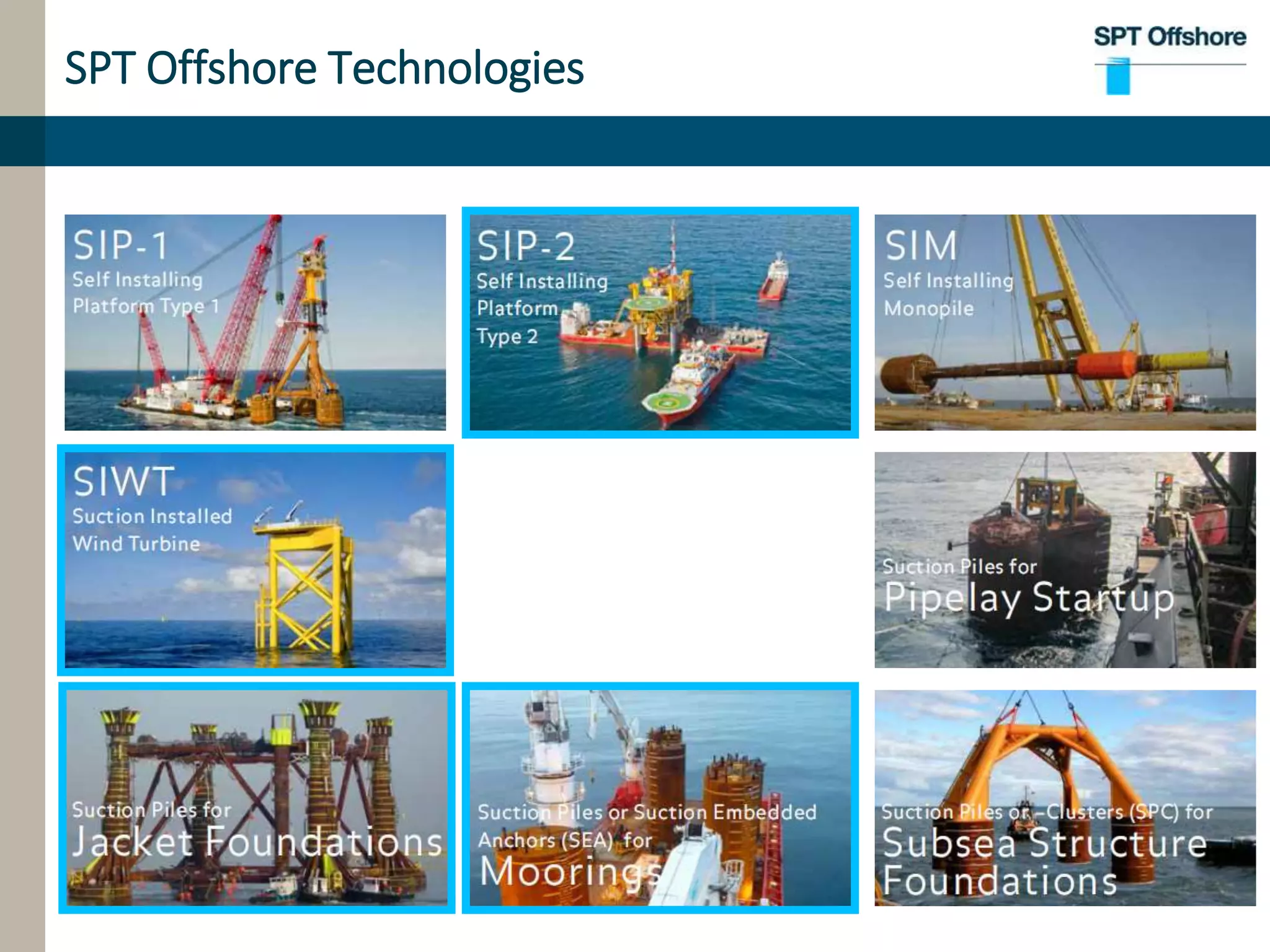

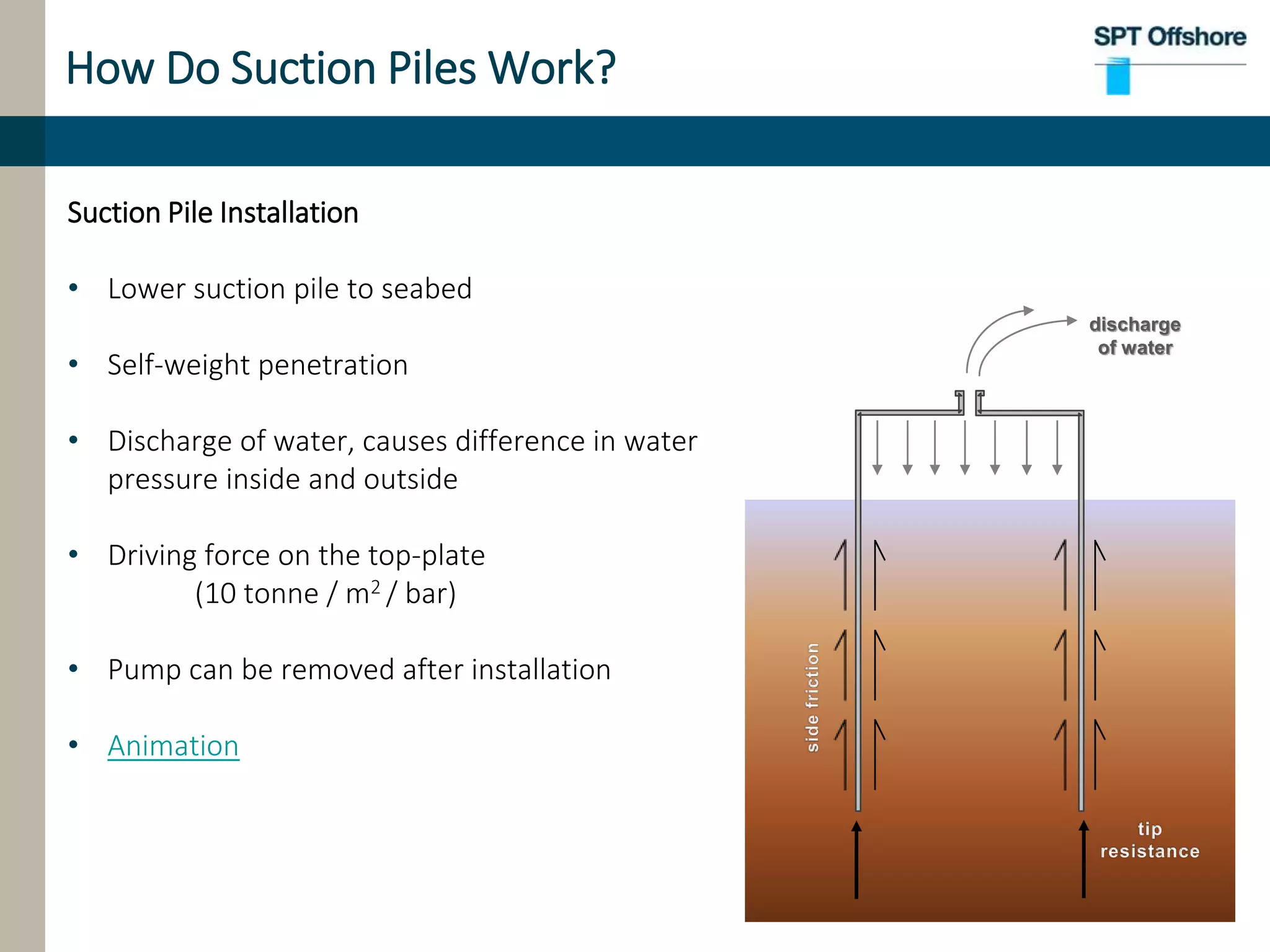

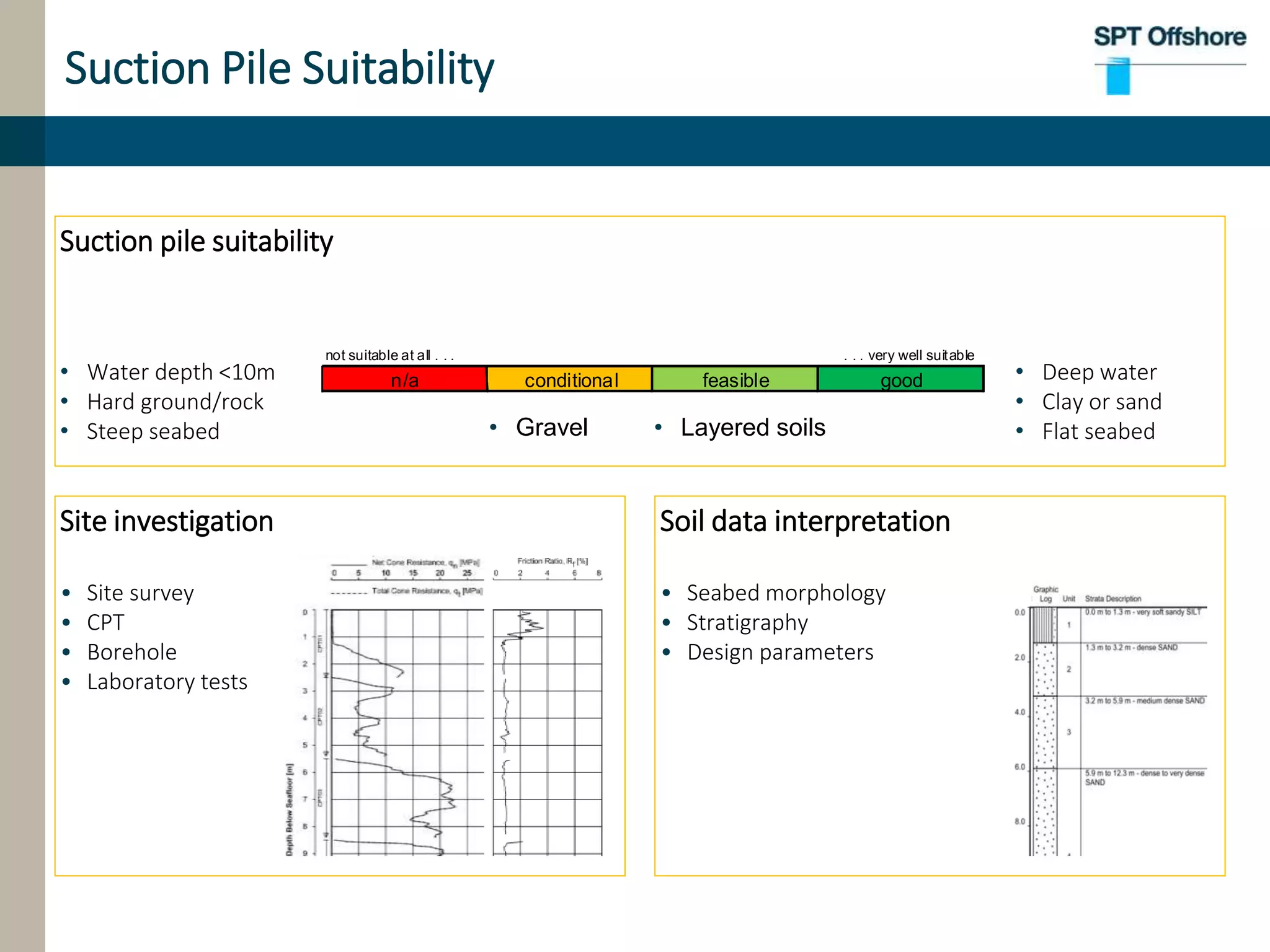

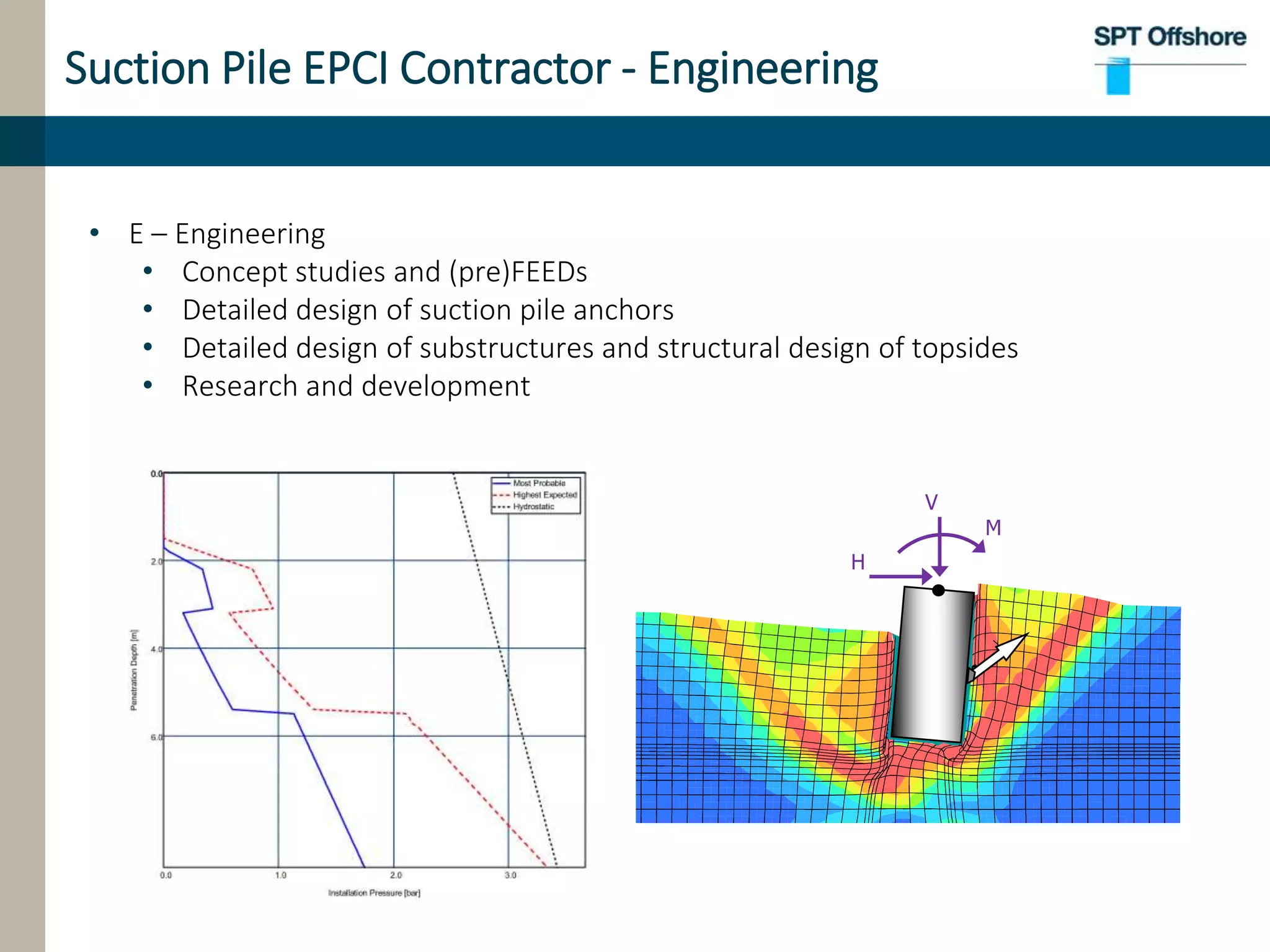

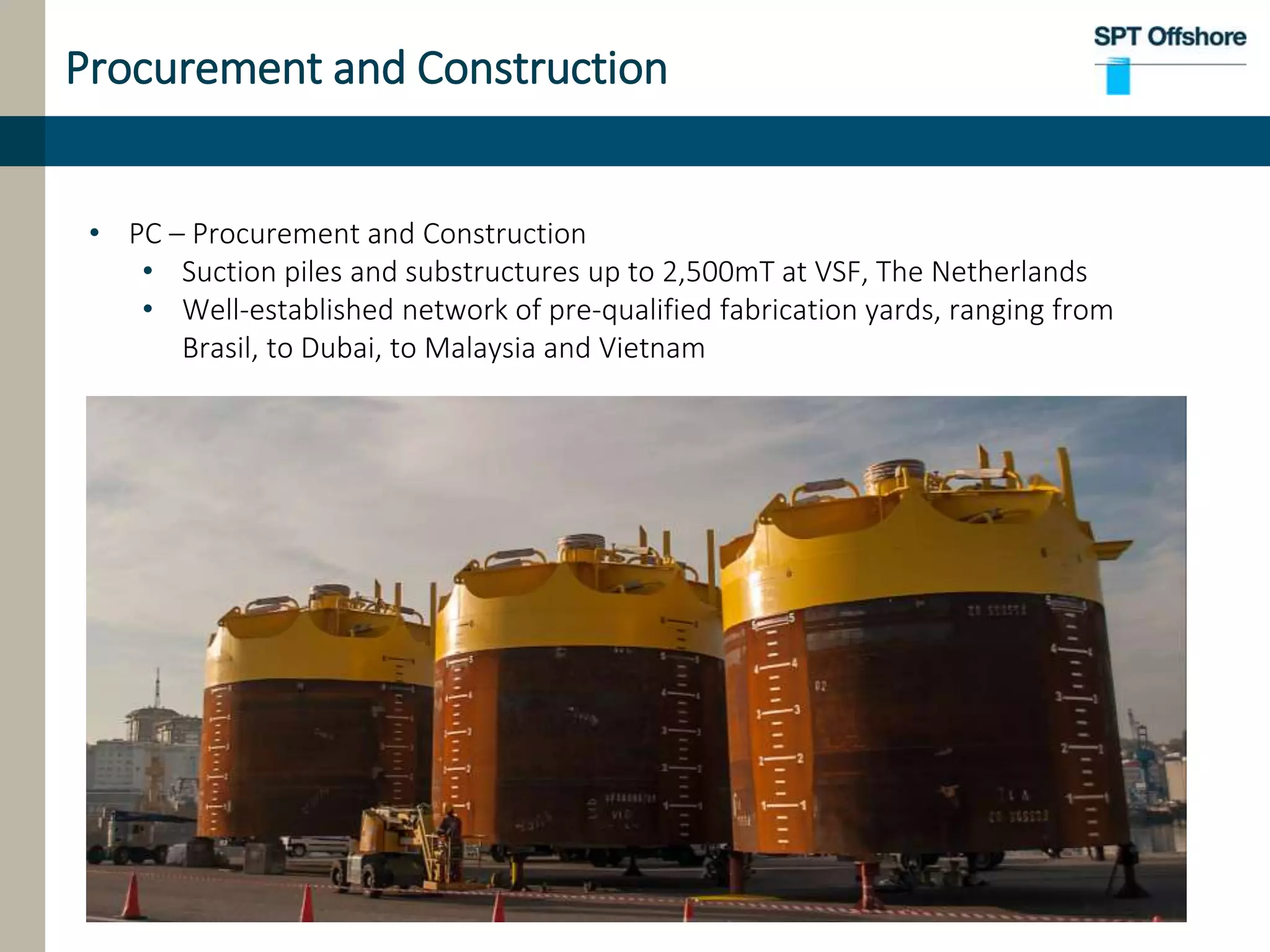

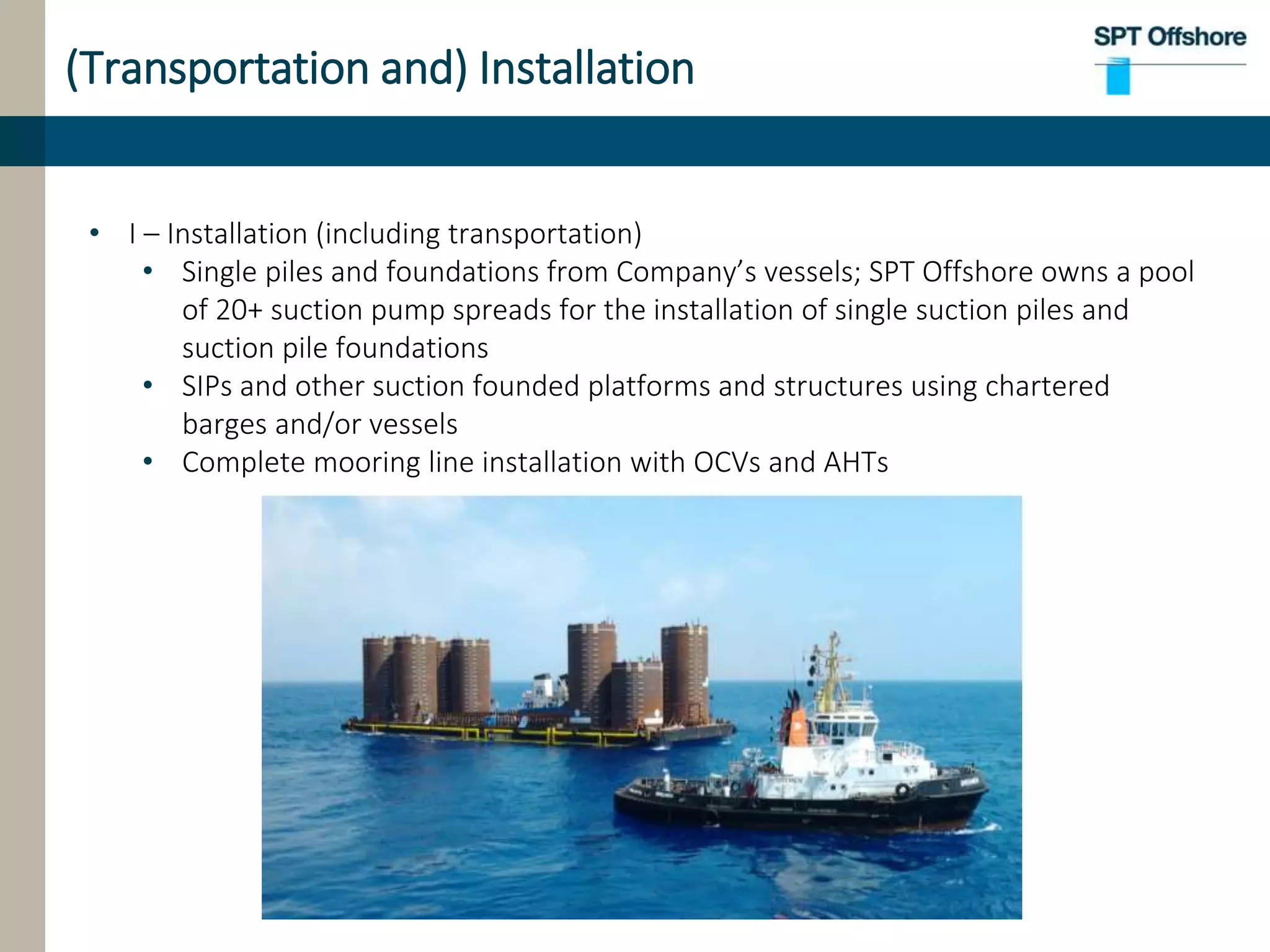

SPT Offshore Technologies is an independent contractor specializing in suction pile foundations and anchors. They have installed over 450 suction piles since 1997 for oil and gas and renewable projects. Suction piles are installed by lowering them to the seabed and pumping out water to create suction, providing a noise-free and environmentally friendly installation method. SPT Offshore provides engineering, procurement, construction, transportation and installation services for suction pile projects worldwide and has over 20 years of experience in the technology.