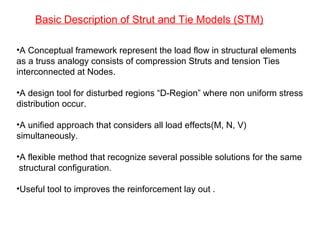

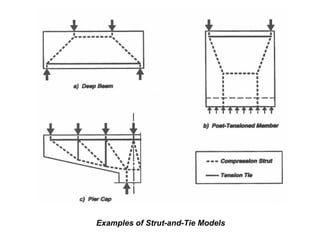

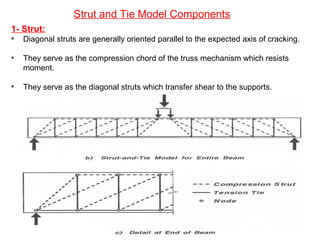

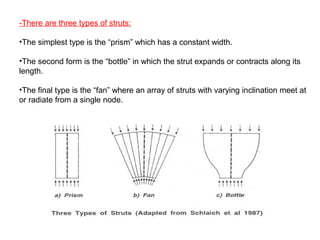

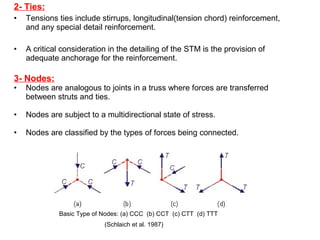

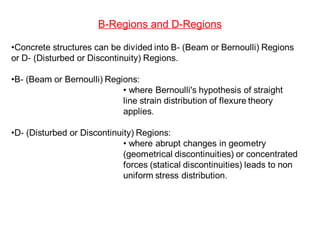

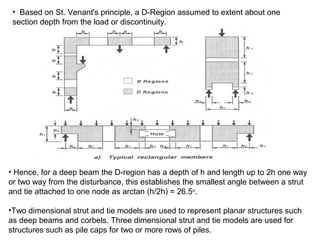

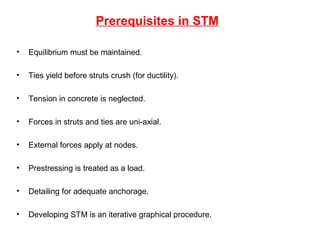

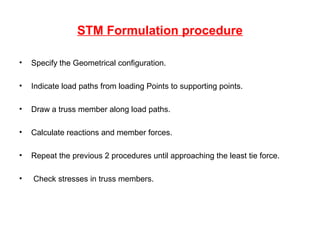

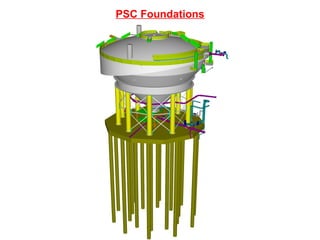

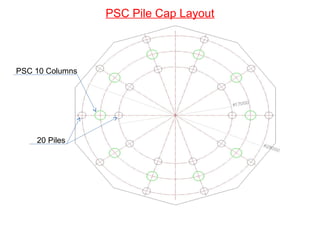

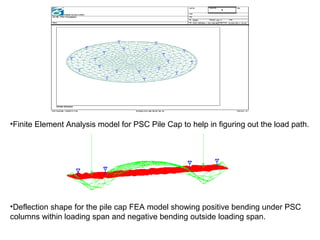

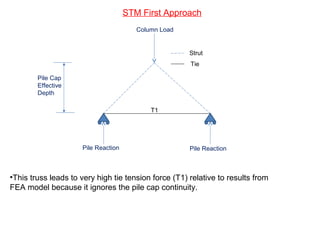

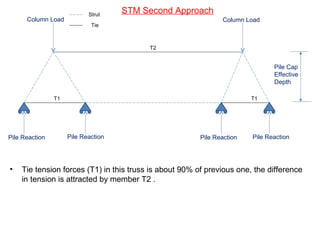

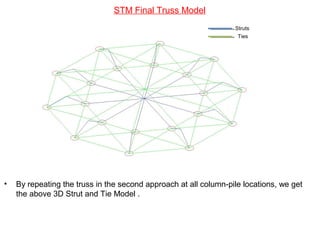

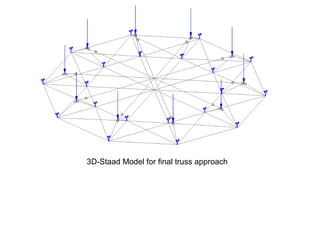

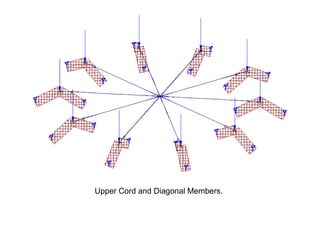

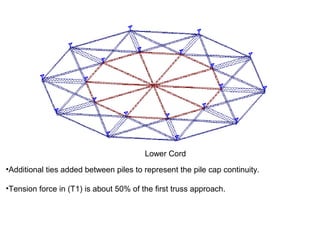

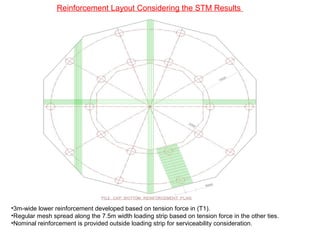

The document discusses the use of strut and tie models (STM) for designing pile caps in PSC foundations, emphasizing their ability to represent load flow effectively in disturbed regions. It highlights various components of STM, including struts, ties, and nodes, and outlines the procedures for developing and analyzing these models to optimize reinforcement layout. The findings indicate that STM provides a more realistic approach for deep structures, enhancing flexibility in design and ensuring adequate reinforcement distribution.