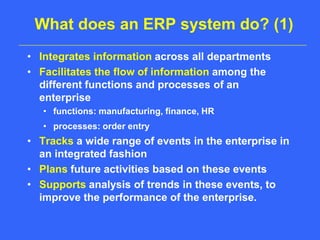

An ERP system integrates information across departments like manufacturing, finance, and HR. It allows inputting data in one place that can then be accessed as reports in real-time. Key drivers for ERP include needing infrastructure for company-wide information, outdated legacy systems, and business process reengineering. While expensive to implement, ERP provides benefits like improved integration, efficiency, information quality, and customer service.