The experiment determined the refrigerating effect, COP, and capacity of an open refrigeration system using a thermostatic expansion valve by running the system until steady-state was reached, recording temperature and pressure readings, calculating the total refrigerating effect based on the water temperature drop and mass of water, and determining the compressor work done and COP using formulas involving the energy meter reading and constants.

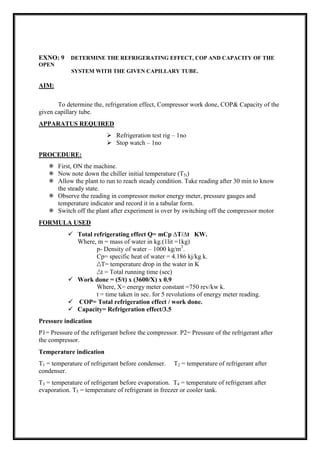

![EXNO: 11 DETERMINE THE COP OF THE GIVEN SEALED SYSTEM USING

ELECTRICAL MEASUREMENTS (WINDOWS AIR CONDITIONER)

AIM

To determine the cop of the given sealed system using electrical measurements

(windows air conditioner)

APPARATUS REQUIRED

Air – conditioning test rig -1no

Stop watch -1no

PROCEDURE

Switch on the mains.

Switch on the condenser, fan and blower.

Switch on the compressor and allow the unit to stabilize or 30 min.

Note down the following.

A] Pressure P1, P2 from the respective pressure gauge.

B] Note the corresponding temperature T1, T2, T3, T4, T5, and T6 at the

respective state points.

C] Note the corresponding voltmeter and ammeter reading.

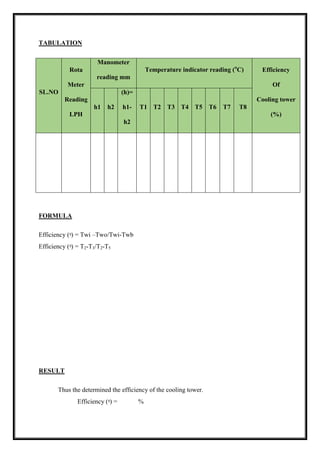

TABULATION

Total

Running

time

(min)

Voltmeter

reading

(volts)

Ammeter

Reading

(Amps)

Pressure

reading

(psi)

Temp reading (0

C)

Velocity

Of air

P1 P2 T1 T2 T3 T4 T5 T6 m/sec](https://image.slidesharecdn.com/raclabmannualfinal-220530153436-146734c2/85/R-AC-LAB-MANNUAL-FINAL-docx-pdf-50-320.jpg)

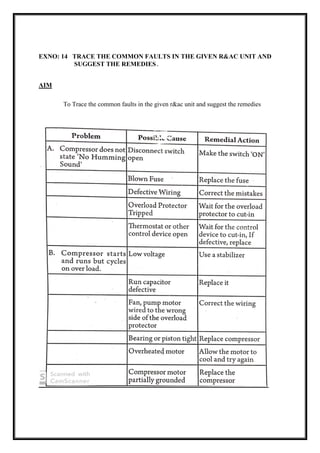

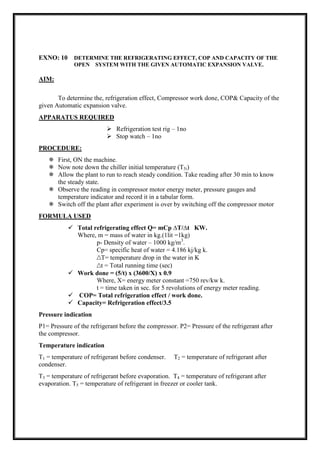

![SPECIFICATION

Compressor details type : 1 ton sealed closed type

Cylinder : single

Refrigerant : R 22

Condenser details : Air cooled

No of passes : 6mm or 1/4”

Pressure drop : 0.5 kg-f / cm2

Expansion device : Capillary tube and thermos tic expansion valve.

Tube material : Copper

Fan : Two nos

230 volts 2 amps : (for condenser and evaporators)

Energy meter : Single phase 230 volts , volt meter and amp.

FORMULA

Mass of air [m] = ρa x A x Va kg/sec

Where, ρa - density of air = 1.125 kg/m3

A - Area of the duct = LXB in m2

Va - Velocity of air in m/sec

Refrigeration effect = m [h2 – h1] kW

Where, ma - mass of air kg/sec

h1 - Enthalpy of before compressor (Refer P-h chart for r22)

h2- Enthalpy of After compressor (Refer P- h chart for r22)

Capacity = Refrigeration effect/3.5

Compressor Work done = ((V X I)/1000) X P.F

Where,

V - Voltmeter reading in volts

I- Ammeter reading in amps

P.F- Power factor = 0,9

COP = [h1- h3]/[ h2- h1]

[Where are h1, h2, h3 enthalpies of refrigerant taken from p-h chart for r22]

h1 - Enthalpy of before compressor

(Compare p-h chart in Low pressure, P1and temperature of compressor entering

temperature,T1)

h2- Enthalpy of after compressor

(Compare p-h chart in High pressure, P2 and temperature of compressor leaving temperature,

T2)](https://image.slidesharecdn.com/raclabmannualfinal-220530153436-146734c2/85/R-AC-LAB-MANNUAL-FINAL-docx-pdf-51-320.jpg)

![EXNO: 12 DETERMINE THE CAPACITY OF A GIVEN WINDOW AIR-

CONDITIONER

AIM

Determine the capacity of a given window air-conditioner

APPARATUS REQUIRED

Air – conditioning test rig -1no

Stop watch -1no

PROCEDURE

Switch on the mains.

Switch on the condenser, fan and blower.

Switch on the compressor and allow the unit to stabilize or 30 min.

Note down the following.

A] Pressure P1, P2 from the respective pressure gauge.

B] Note the corresponding temperature T1, T2, T3, T4, T5, and T6 at the

respective state points.

C] Note the corresponding voltmeter and ammeter reading.

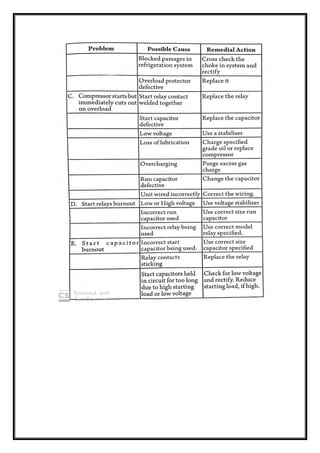

TABULATION

Total

Running

time

(min)

Voltmeter

reading

(volts)

Ammeter

Reading

(Amps)

Pressure

reading

(psi)

Temp reading (0

C)

Velocity

Of air

P1 P2 T1 T2 T3 T4 T5 T6 m/sec](https://image.slidesharecdn.com/raclabmannualfinal-220530153436-146734c2/85/R-AC-LAB-MANNUAL-FINAL-docx-pdf-53-320.jpg)

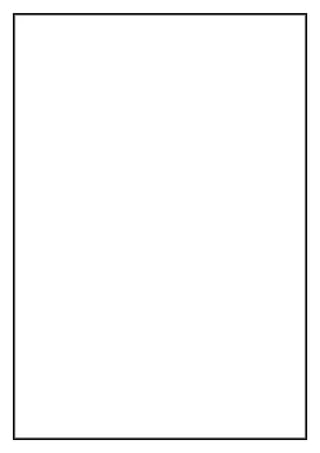

![SPECIFICATION

Compressor details type : 1 ton sealed closed type

Cylinder : single

Refrigerant : R 22

Condenser details : Air cooled

No of passes : 6mm or 1/4”

Pressure drop : 0.5 kg-f / cm2

Expansion device : Capillary tube and thermos tic expansion valve.

Tube material : Copper

Fan : Two nos

230 volts 2 amps : (for condenser and evaporators)

Energy meter : Single phase 230 volts , volt meter and amp.

FORMULA

Mass of air [m] = ρa x A x Va kg/sec

Where, ρa - density of air = 1.125 kg/m3

A - Area of the duct = LXB in m2

Va - Velocity of air in m/sec

Refrigeration effect = m [h2 – h1] kW

Where, ma - mass of air kg/sec

h1 - Enthalpy of before compressor (Refer P-h chart for r22)

h2- Enthalpy of After compressor (Refer P- h chart for r22)

Capacity = Refrigeration effect/3.5

Compressor Work done = ((V X I)/1000) X P.F

Where,

V - Voltmeter reading in volts

I- Ammeter reading in amps

P.F- Power factor = 0.9

COP = [h1- h3]/[ h2- h1]

[Where are h1, h2, h3 enthalpies of refrigerant taken from p-h chart for r22]

h1 - Enthalpy of before compressor

(Compare p-h chart in Low pressure, P1and temperature of compressor entering

temperature,T1)](https://image.slidesharecdn.com/raclabmannualfinal-220530153436-146734c2/85/R-AC-LAB-MANNUAL-FINAL-docx-pdf-54-320.jpg)