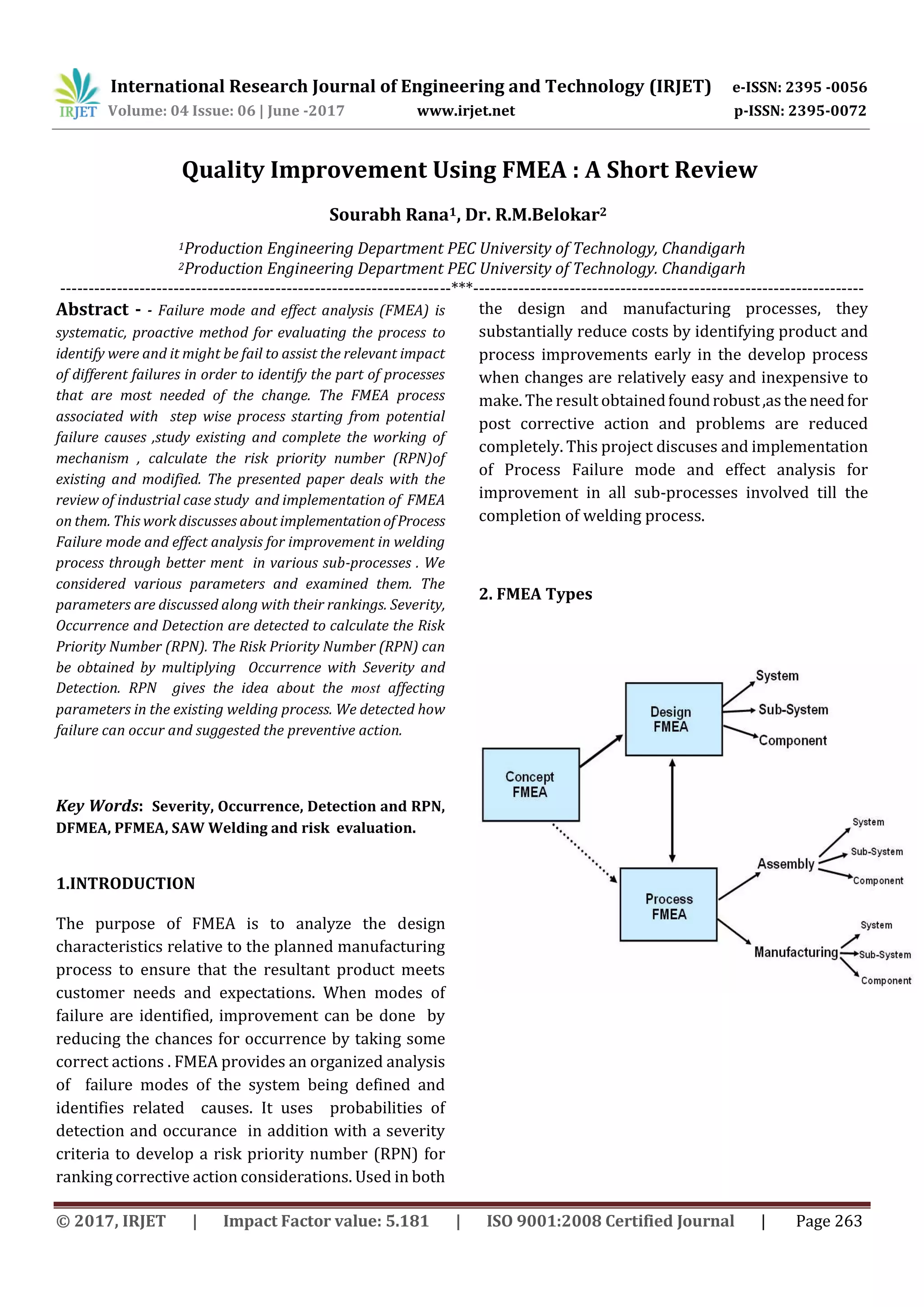

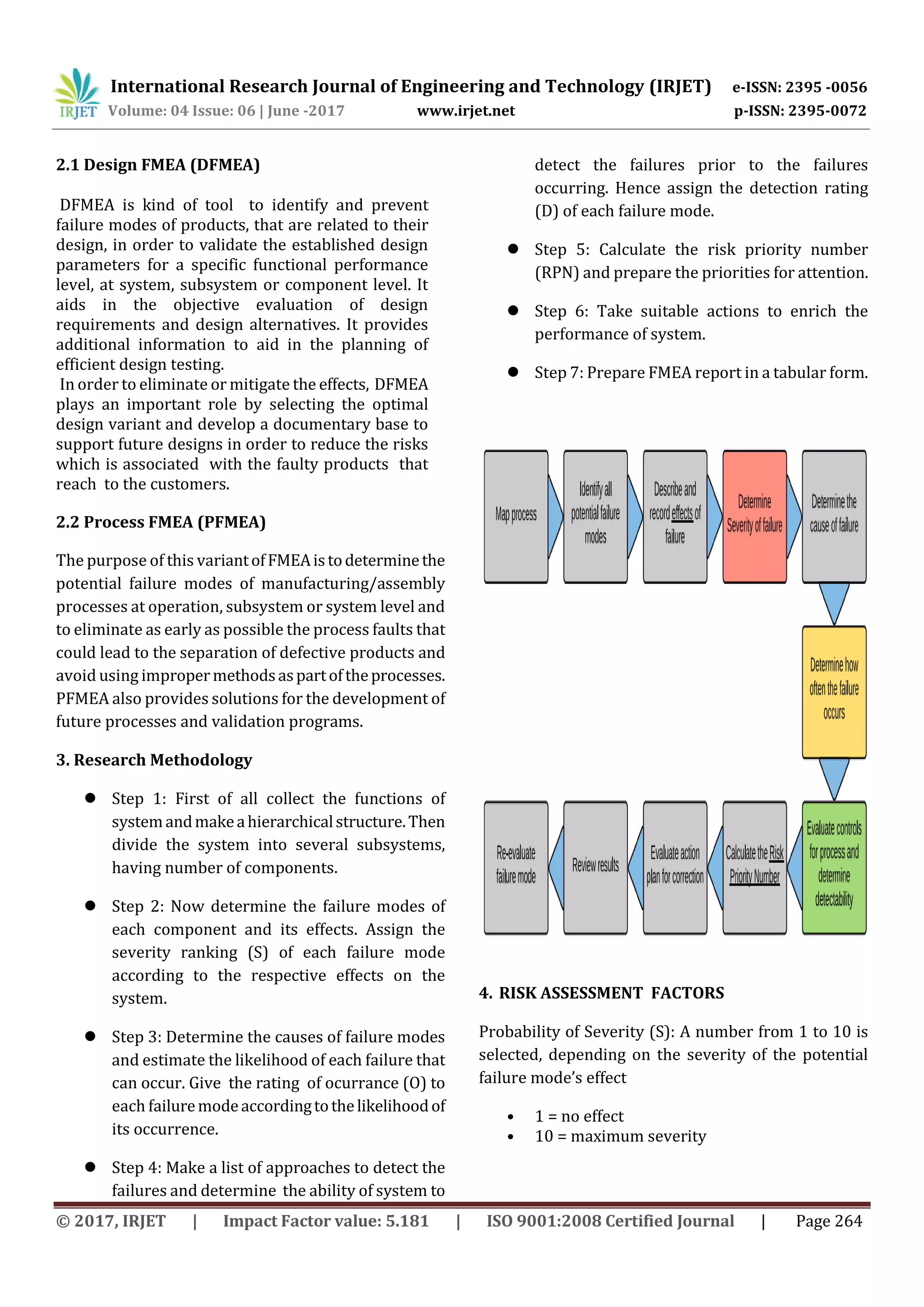

This document discusses failure mode and effect analysis (FMEA) and its application to improve welding processes. FMEA is a systematic method to evaluate potential failure modes, identify causes and effects, and prioritize issues based on severity, occurrence, and detection ratings. The document provides an overview of FMEA types (design and process FMEA), methodology including calculating a risk priority number, and applications. It then discusses implementing FMEA to analyze sub-processes in welding, identify the most critical issues, and suggest preventative actions to improve quality.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 04 Issue: 06 | June -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 266

5. Applications

Used in the design of products and processes

(manufacturing line, service procedures, etc.)

to anticipate and address potential failure

modes early in the process when they are least

expensive for correction.

It contributes to the development of effective

maintenance procedures. For instance, MSG-3

analysis for aircraft industry.

Identifies the failure modes discovered during

testing and update the probabilities of

occurrence based on the Reliability Growth

testing data.

It is used to evaluate critical plans to modify an

existing process.

Used to investigate the credibility of existing

systems/processes.

Helps in providing a central location for

reliability-related information for the process.

Provides a basic knowledge that helps for the

future troubleshooting efforts.

Acts as a learning tool for new engineers.

It provides input to other system analyses, for

example ReliabilityBlockDiagram(RBD),Fault

Tree, etc.

It can be used to Contribute in the

identification of requirements for built-in test

equipment (BITE).

It is also included among Probabilistic Risk

Assessment (PRA) techniques (such as in

nuclear power and other industries).

It is performed to satisfy a customer

requirement and/or to comply with Safetyand

Quality requirements, such as:

o Six Sigma

o FDA Good Manufacturing Practices

o Process Safety Management Act (PSM

act)

6. Conclusion

In 1950s the attention was paid to the safety to

prevent accidents that canbepredictedinaerospace

industry in advance led to the development of the

FMEA methodology. Later, it was introduced as key

tool for increasing efficiency and quality in

manufacturing processes. In 1970’s automobile

company came with FMEA to address the potential

problemsintheResearchandDevelopment(R&D)in

the early stage of production and published the

Potential Failure Mode and Effects Analysis

Handbook in 1984 to promote FMEA. FMEA

methodology is now effectively used in a variety

of industries including semiconductor, processing,

food service, plastics, software, and healthcare.

Several approaches and applications of FMEA have

been developed so far. FMEA can be used to

optimize the decision making process in new

product developmentin automobile industry.FMEA

can be implemented at the design stage once actual

failures are observed during test, production and

operation.

On the basis of results and analysis stated above we

are going to implement FMEA on the sub processes

involved in welding processes starting from the

sheet handling to welding process.

7. Reference

[1] A. A. Nannikar, D. N. Raut, M. Chanmanwar, S. B.

Kamble and D. B. Patil, “FMEA for Manufacturing and

Assembly Process”, International Conference on

Technology and Business Management, pp. 26-28,

March 2012.

[2] Segismundo, Paulo CauchickMiguel,"Failuremode

and effects analysis (FMEA) in the context of risk

management in new product development: A case

study in an automotive company", International

Journal of Quality & Reliability Management, Volume

25 Issue 9, pp.89 – 912, 2008.

[3] Arabian-Hoseynabadi, H. and Oraee, H. andTavner,

P. J. “Failure Modes and Effects Analysis (FMEA) ”,

International journal of electrical power and energy

systems, Issue 7, pp. 817-824, 2010.

[4] ArunChauhan, Raj Kamal Malik, Gaurav Sharma,

MukeshVerma, “Performance Evaluation of Casting

Industry by FMEA - A Case Study”, International

Journal of Mechanical Engineering Applications

Research, Volume 2, Issue 2, pp. 113-121, 2011.

[5] Carl S. Carlson, “Understanding and applying the

fundamental of FMEAs”, IEEE, January 2014.](https://image.slidesharecdn.com/irjet-v4i645-180120100546/75/Quality-Improvement-using-FMEA-A-Short-Review-4-2048.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 04 Issue: 06 | June -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 267

[6] Dr. D.R.Prajapati, “Application of FMEA in Casting

Industries: A case study”, UdyogPragati,vol.35,Issue4,

pp. 6-14,December 2011.

[7] Ioannis S. Arvanitoyannis and Theodoros H.

Varzakas, “Application of ISO 22000 and failure mode

and effect analysis [FMEA] for industrial processing of

salmon: A case study”, Critical reviews in Food science

and Nutrition, Volume 48, pp. 411-429,2008.

[8] Rakesh.R Bobin Cherian Jos and George Mathew,

“FMEA Analysis for Reducing Breakdowns of a Sub

System in the Life Care Product Manufacturing.](https://image.slidesharecdn.com/irjet-v4i645-180120100546/75/Quality-Improvement-using-FMEA-A-Short-Review-5-2048.jpg)