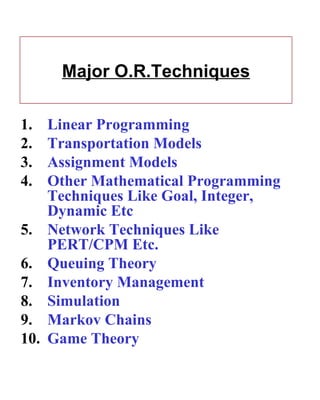

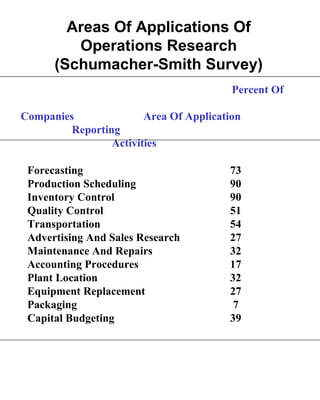

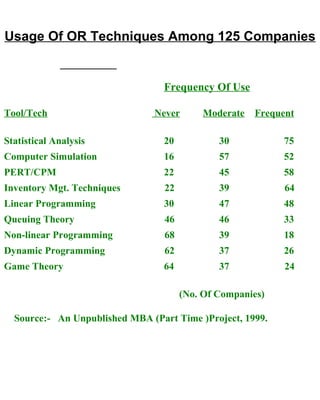

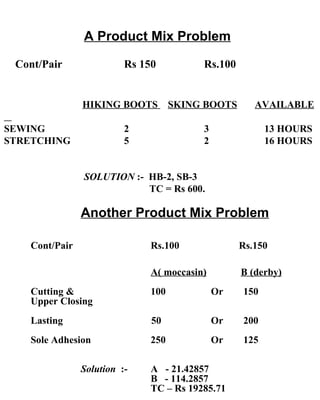

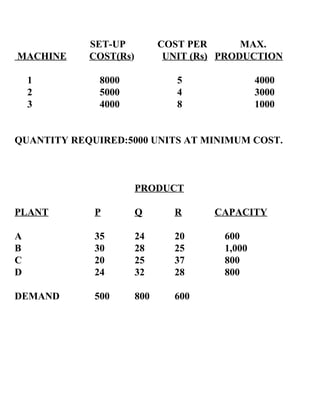

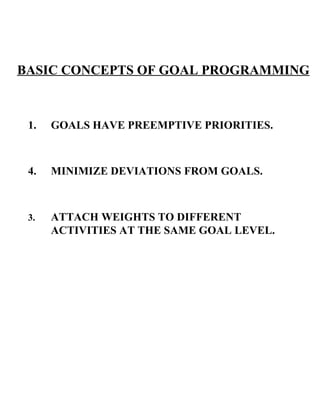

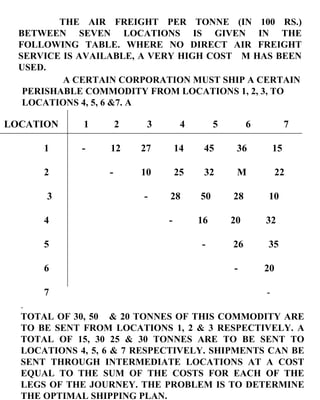

This document discusses operations research (OR) and its role in managerial decision making. It provides definitions of OR, describes common OR techniques like linear programming, and gives examples of OR applications in areas like production, marketing, finance, and personnel management. It also discusses the evolution of OR over multiple generations and limitations of linear programming as an OR technique. Several examples of linear programming problems in manufacturing and logistics settings are presented to illustrate the use of LP models.