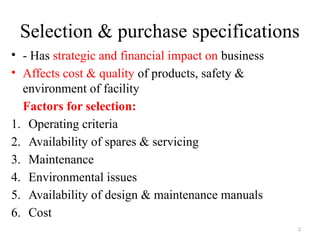

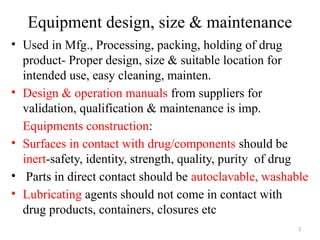

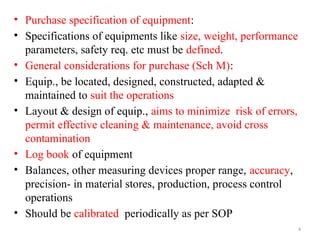

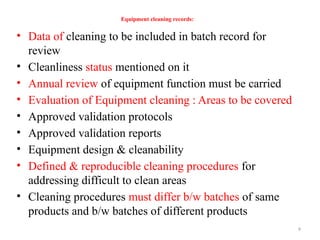

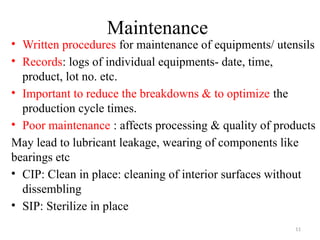

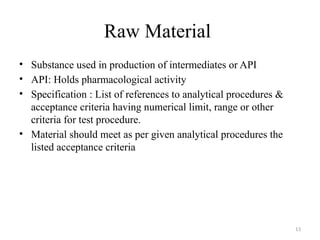

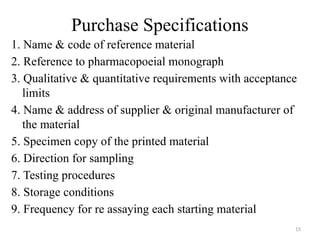

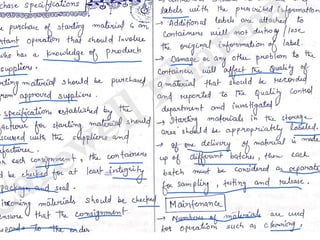

The document outlines the critical requirements for equipment selection, cleaning, and maintenance in drug manufacturing, emphasizing their impact on product quality and safety. It details specifications for purchasing equipment, cleaning procedures, and the importance of proper maintenance to prevent contamination and equipment failure. Additionally, it highlights the necessity for strict protocols and documentation, including cleaning records and storage conditions for raw materials and products.