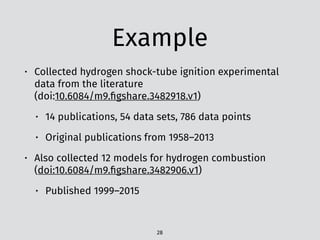

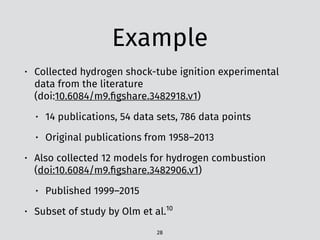

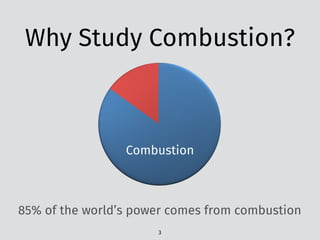

The document discusses PyTeck, a Python-based testing package designed for chemical kinetic models, emphasizing its relevance to combustion research, which accounts for 85% of the world's power. It covers various topics including the construction and validation of jet-stirred reactors and the complexities of ignition delay times in different fuel-air mixtures under varying pressures and temperatures. Additionally, it explores qualitative versus quantitative challenges in combustion modeling and presents mechanisms relating to fuels like toluene and n-heptane.

![The problem:

experimental data

12

PDF table5

t [ms3 ~- metric benzene-air mixture.

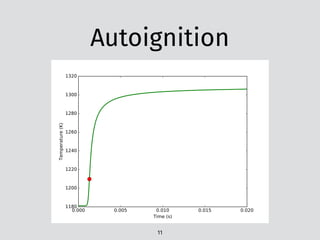

region the dependence of the ignition delay

time upon temperature can be expressed ap-

proximately by straight lines in the Arrhenius

plot. The corresponding global activation ener-

gies decrease with increasing pressure.

For Ps around 13.5 bar the dependence be-

comes strongly nonlinear in a temperature

range between 950 and 700 K. In this interme-

diate temperature region a decrease in ignition

delay time is observed with decreasing temper-

atures. This leads to an S-shaped curve with a

maximum and a minimum. Between both ex-

termal values the dependence possesses a neg-

ative temperature coefficient. The position of

this transition region shifts to higher tempera-

tures with increasing pressures Ps- In the low-

temperature region--below approximately 700

K--the dependence of the ignition delay time

upon temperature can again be expressed by a

linear dependence. Because the measuring time

of the shock tube is limited, the delay times

could be determined only above 660 K, so that

only a short part of the low-temperature region

could be investigated in our experiments. The

influence of pressure on the ignition delay is

most pronounced in the transition region,

smallest for low temperatures and of varying

degree in the high-temperature region, where

with increasing temperature this dependence

becomes smaller.

"1~z

[ms]

101

100

1o-1

162

,, 3.2bar ,,./--~-~.~ /.-'~

o 6.s ,, ./ '---J.//

O I£3 " / ' / n [] ..~-/

30 ,,,, .o

,~_ D,,- x i< 3 bar 1 Comoufofion

~o/"°E~/" × ~+.---+-.---L_._.+_.~..~" ~ X13 " ,, [ , " ,

t/~ / /" !.ine of /+0 " j el'. a[.

/.z~ ~/ ./ pressure variation

,/~// T=9/,0 K (Fig.11) T

/ 1200 1000 800 [K]

I I I i I I I I I l I

0:8 1.o 1.2 114 loooK

T

Fig. 3. Ignition delay times.

Figure6](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-30-320.jpg)

![The problem:

experimental data

12

PDF table5

t [ms3 ~- metric benzene-air mixture.

region the dependence of the ignition delay

time upon temperature can be expressed ap-

proximately by straight lines in the Arrhenius

plot. The corresponding global activation ener-

gies decrease with increasing pressure.

For Ps around 13.5 bar the dependence be-

comes strongly nonlinear in a temperature

range between 950 and 700 K. In this interme-

diate temperature region a decrease in ignition

delay time is observed with decreasing temper-

atures. This leads to an S-shaped curve with a

maximum and a minimum. Between both ex-

termal values the dependence possesses a neg-

ative temperature coefficient. The position of

this transition region shifts to higher tempera-

tures with increasing pressures Ps- In the low-

temperature region--below approximately 700

K--the dependence of the ignition delay time

upon temperature can again be expressed by a

linear dependence. Because the measuring time

of the shock tube is limited, the delay times

could be determined only above 660 K, so that

only a short part of the low-temperature region

could be investigated in our experiments. The

influence of pressure on the ignition delay is

most pronounced in the transition region,

smallest for low temperatures and of varying

degree in the high-temperature region, where

with increasing temperature this dependence

becomes smaller.

"1~z

[ms]

101

100

1o-1

162

,, 3.2bar ,,./--~-~.~ /.-'~

o 6.s ,, ./ '---J.//

O I£3 " / ' / n [] ..~-/

30 ,,,, .o

,~_ D,,- x i< 3 bar 1 Comoufofion

~o/"°E~/" × ~+.---+-.---L_._.+_.~..~" ~ X13 " ,, [ , " ,

t/~ / /" !.ine of /+0 " j el'. a[.

/.z~ ~/ ./ pressure variation

,/~// T=9/,0 K (Fig.11) T

/ 1200 1000 800 [K]

I I I i I I I I I l I

0:8 1.o 1.2 114 loooK

T

Fig. 3. Ignition delay times.

Figure6

# n-heptane ignition delay from Colket and Spadaccini 2001

# P (atm), T (K), Ignition Delay (µs)

# Mole Fraction nC7H16 O2 Ar : 0.00192 0.04224 0.95584

7.72 ,1393 ,85

7.78 ,1299 ,345

7.04 ,1235 ,631

6.38 ,1299 ,348

7.53 ,1372 ,134

6.08 ,1236 ,678

7.35 ,1340 ,148

6.63 ,1328 ,211

6.94 ,1395 ,89

CSV file7](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-31-320.jpg)

![The problem:

experimental data

12

PDF table5

t [ms3 ~- metric benzene-air mixture.

region the dependence of the ignition delay

time upon temperature can be expressed ap-

proximately by straight lines in the Arrhenius

plot. The corresponding global activation ener-

gies decrease with increasing pressure.

For Ps around 13.5 bar the dependence be-

comes strongly nonlinear in a temperature

range between 950 and 700 K. In this interme-

diate temperature region a decrease in ignition

delay time is observed with decreasing temper-

atures. This leads to an S-shaped curve with a

maximum and a minimum. Between both ex-

termal values the dependence possesses a neg-

ative temperature coefficient. The position of

this transition region shifts to higher tempera-

tures with increasing pressures Ps- In the low-

temperature region--below approximately 700

K--the dependence of the ignition delay time

upon temperature can again be expressed by a

linear dependence. Because the measuring time

of the shock tube is limited, the delay times

could be determined only above 660 K, so that

only a short part of the low-temperature region

could be investigated in our experiments. The

influence of pressure on the ignition delay is

most pronounced in the transition region,

smallest for low temperatures and of varying

degree in the high-temperature region, where

with increasing temperature this dependence

becomes smaller.

"1~z

[ms]

101

100

1o-1

162

,, 3.2bar ,,./--~-~.~ /.-'~

o 6.s ,, ./ '---J.//

O I£3 " / ' / n [] ..~-/

30 ,,,, .o

,~_ D,,- x i< 3 bar 1 Comoufofion

~o/"°E~/" × ~+.---+-.---L_._.+_.~..~" ~ X13 " ,, [ , " ,

t/~ / /" !.ine of /+0 " j el'. a[.

/.z~ ~/ ./ pressure variation

,/~// T=9/,0 K (Fig.11) T

/ 1200 1000 800 [K]

I I I i I I I I I l I

0:8 1.o 1.2 114 loooK

T

Fig. 3. Ignition delay times.

Figure6

# n-heptane ignition delay from Colket and Spadaccini 2001

# P (atm), T (K), Ignition Delay (µs)

# Mole Fraction nC7H16 O2 Ar : 0.00192 0.04224 0.95584

7.72 ,1393 ,85

7.78 ,1299 ,345

7.04 ,1235 ,631

6.38 ,1299 ,348

7.53 ,1372 ,134

6.08 ,1236 ,678

7.35 ,1340 ,148

6.63 ,1328 ,211

6.94 ,1395 ,89

CSV file7 Email plea](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-32-320.jpg)

![The problem:

qualitative vs. quantitative

13

del

ne,

ne,

Re-

ng

ev-

he

an

ee-

ha-

ed

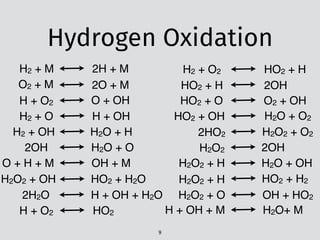

by sensitivity analysis [25–27], except for the small molecules

(i.e., C2H2, C2H3, CH2CO, HCCO, et al.) included in three-component

fuels mechanism [22]. Finally, a reduced sub-mechanism of tolu-

ene oxidation is formed and presented in Supplementary data A.

2.2. The sub-mechanism of DIB

A detailed mechanism considered two isomers of DIB, i.e. 2,4,

4-trimethyl-1-pentene (JC8H16) and 2,4,4-trimethyl-2-pentene

(IC8H16), was developed by Metcalfe et al. [28]. The detailed model

consists of 897 species and 3783 elementary reactions. However,

0.1

1

10

100

Toluene/N-heptane/air

Expt. Present

P = 5MPa

P = 3MPa

P = 1MPa

1000/T (1/K)

Ignitiondelaytime(ms)

(a) φ=1.0

0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

1

10

100

Expt. Present

P = 5MPa

P = 3MPa

Toluene/N-heptane/air

Ignitiondelaytime(ms)](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-34-320.jpg)

![The problem:

qualitative vs. quantitative

13

del

ne,

ne,

Re-

ng

ev-

he

an

ee-

ha-

ed

by sensitivity analysis [25–27], except for the small molecules

(i.e., C2H2, C2H3, CH2CO, HCCO, et al.) included in three-component

fuels mechanism [22]. Finally, a reduced sub-mechanism of tolu-

ene oxidation is formed and presented in Supplementary data A.

2.2. The sub-mechanism of DIB

A detailed mechanism considered two isomers of DIB, i.e. 2,4,

4-trimethyl-1-pentene (JC8H16) and 2,4,4-trimethyl-2-pentene

(IC8H16), was developed by Metcalfe et al. [28]. The detailed model

consists of 897 species and 3783 elementary reactions. However,

0.1

1

10

100

Toluene/N-heptane/air

Expt. Present

P = 5MPa

P = 3MPa

P = 1MPa

1000/T (1/K)

Ignitiondelaytime(ms)

(a) φ=1.0

0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

1

10

100

Expt. Present

P = 5MPa

P = 3MPa

Toluene/N-heptane/air

Ignitiondelaytime(ms)

“…the calculations show

good agreements with

experiments…”8](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-35-320.jpg)

![The problem:

qualitative vs. quantitative

13

del

ne,

ne,

Re-

ng

ev-

he

an

ee-

ha-

ed

by sensitivity analysis [25–27], except for the small molecules

(i.e., C2H2, C2H3, CH2CO, HCCO, et al.) included in three-component

fuels mechanism [22]. Finally, a reduced sub-mechanism of tolu-

ene oxidation is formed and presented in Supplementary data A.

2.2. The sub-mechanism of DIB

A detailed mechanism considered two isomers of DIB, i.e. 2,4,

4-trimethyl-1-pentene (JC8H16) and 2,4,4-trimethyl-2-pentene

(IC8H16), was developed by Metcalfe et al. [28]. The detailed model

consists of 897 species and 3783 elementary reactions. However,

0.1

1

10

100

Toluene/N-heptane/air

Expt. Present

P = 5MPa

P = 3MPa

P = 1MPa

1000/T (1/K)

Ignitiondelaytime(ms)

(a) φ=1.0

0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

1

10

100

Expt. Present

P = 5MPa

P = 3MPa

Toluene/N-heptane/air

Ignitiondelaytime(ms)

“…the calculations show

good agreements with

experiments…”8

“…although there is a

mismatch […] at […] T < 1000 K.”](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-36-320.jpg)

![The problem:

qualitative vs. quantitative

13

del

ne,

ne,

Re-

ng

ev-

he

an

ee-

ha-

ed

by sensitivity analysis [25–27], except for the small molecules

(i.e., C2H2, C2H3, CH2CO, HCCO, et al.) included in three-component

fuels mechanism [22]. Finally, a reduced sub-mechanism of tolu-

ene oxidation is formed and presented in Supplementary data A.

2.2. The sub-mechanism of DIB

A detailed mechanism considered two isomers of DIB, i.e. 2,4,

4-trimethyl-1-pentene (JC8H16) and 2,4,4-trimethyl-2-pentene

(IC8H16), was developed by Metcalfe et al. [28]. The detailed model

consists of 897 species and 3783 elementary reactions. However,

0.1

1

10

100

Toluene/N-heptane/air

Expt. Present

P = 5MPa

P = 3MPa

P = 1MPa

1000/T (1/K)

Ignitiondelaytime(ms)

(a) φ=1.0

0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

1

10

100

Expt. Present

P = 5MPa

P = 3MPa

Toluene/N-heptane/air

Ignitiondelaytime(ms)

model. Figure 5 shows the comparison of the igni-

tion delay times of PRF/toluene mixtures at 25

and 50 atm [1]. The species mole fractions in the

oxidation of PRF/toluene at 12.5 atm obtained

by a flow reactor experiment [7] are compared in

Fig. 6. Those figures indicate that the present

model well predicts the reactivity of PRF/toluene

mixtures at wide range of temperature and pres-

(dashed

addition

reproduc

mixtures

of cross

Reac

perform

PRF/tol

10

0.6 0.7 0.8 0.9

T-1

(103

K-1

)

12 atm

50 atm

Fig. 2. Comparisons of measured and simulated ignition

delay times of toluene at the equivalence ratio of 0.5%

and 1.2% fuels diluted in Ar or air behind reflected shock

waves at 2 [33], 15 and 50 atm [34]. Solid curves: present

model, dashed curves: Pitz model.

10

100

1000

10000

0.75 0.80 0.85 0.90 0.95 1.00

T-1

(103

K-1

)

Ignitiondelaytimes(µs)

Fig. 3. Comparisons of measured and simulated ignition

delay times of toluene behind reflected shock waves at

50 atm [34]. Solid curves: present model, dashed curves:

Pitz model.

0.00

Fig. 4.

CO + CO

by the flo

of initial

dashed cu

1

10

70

Ignitiondelaytimes(µs)

Fig. 5. C

delay tim

heptane/i

shock wa

present m

“…the calculations show

good agreements with

experiments…”8

“…although there is a

mismatch […] at […] T < 1000 K.”](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-37-320.jpg)

![The problem:

qualitative vs. quantitative

13

del

ne,

ne,

Re-

ng

ev-

he

an

ee-

ha-

ed

by sensitivity analysis [25–27], except for the small molecules

(i.e., C2H2, C2H3, CH2CO, HCCO, et al.) included in three-component

fuels mechanism [22]. Finally, a reduced sub-mechanism of tolu-

ene oxidation is formed and presented in Supplementary data A.

2.2. The sub-mechanism of DIB

A detailed mechanism considered two isomers of DIB, i.e. 2,4,

4-trimethyl-1-pentene (JC8H16) and 2,4,4-trimethyl-2-pentene

(IC8H16), was developed by Metcalfe et al. [28]. The detailed model

consists of 897 species and 3783 elementary reactions. However,

0.1

1

10

100

Toluene/N-heptane/air

Expt. Present

P = 5MPa

P = 3MPa

P = 1MPa

1000/T (1/K)

Ignitiondelaytime(ms)

(a) φ=1.0

0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

1

10

100

Expt. Present

P = 5MPa

P = 3MPa

Toluene/N-heptane/air

Ignitiondelaytime(ms)

model. Figure 5 shows the comparison of the igni-

tion delay times of PRF/toluene mixtures at 25

and 50 atm [1]. The species mole fractions in the

oxidation of PRF/toluene at 12.5 atm obtained

by a flow reactor experiment [7] are compared in

Fig. 6. Those figures indicate that the present

model well predicts the reactivity of PRF/toluene

mixtures at wide range of temperature and pres-

(dashed

addition

reproduc

mixtures

of cross

Reac

perform

PRF/tol

10

0.6 0.7 0.8 0.9

T-1

(103

K-1

)

12 atm

50 atm

Fig. 2. Comparisons of measured and simulated ignition

delay times of toluene at the equivalence ratio of 0.5%

and 1.2% fuels diluted in Ar or air behind reflected shock

waves at 2 [33], 15 and 50 atm [34]. Solid curves: present

model, dashed curves: Pitz model.

10

100

1000

10000

0.75 0.80 0.85 0.90 0.95 1.00

T-1

(103

K-1

)

Ignitiondelaytimes(µs)

Fig. 3. Comparisons of measured and simulated ignition

delay times of toluene behind reflected shock waves at

50 atm [34]. Solid curves: present model, dashed curves:

Pitz model.

0.00

Fig. 4.

CO + CO

by the flo

of initial

dashed cu

1

10

70

Ignitiondelaytimes(µs)

Fig. 5. C

delay tim

heptane/i

shock wa

present m

“In general, the present

model predicts well the

reactivity of […] mixtures…”9

“…the calculations show

good agreements with

experiments…”8

“…although there is a

mismatch […] at […] T < 1000 K.”](https://image.slidesharecdn.com/scipy2016-pyteck-160713162513/85/PyTeCK-A-Python-based-automatic-testing-package-for-chemical-kinetic-models-38-320.jpg)