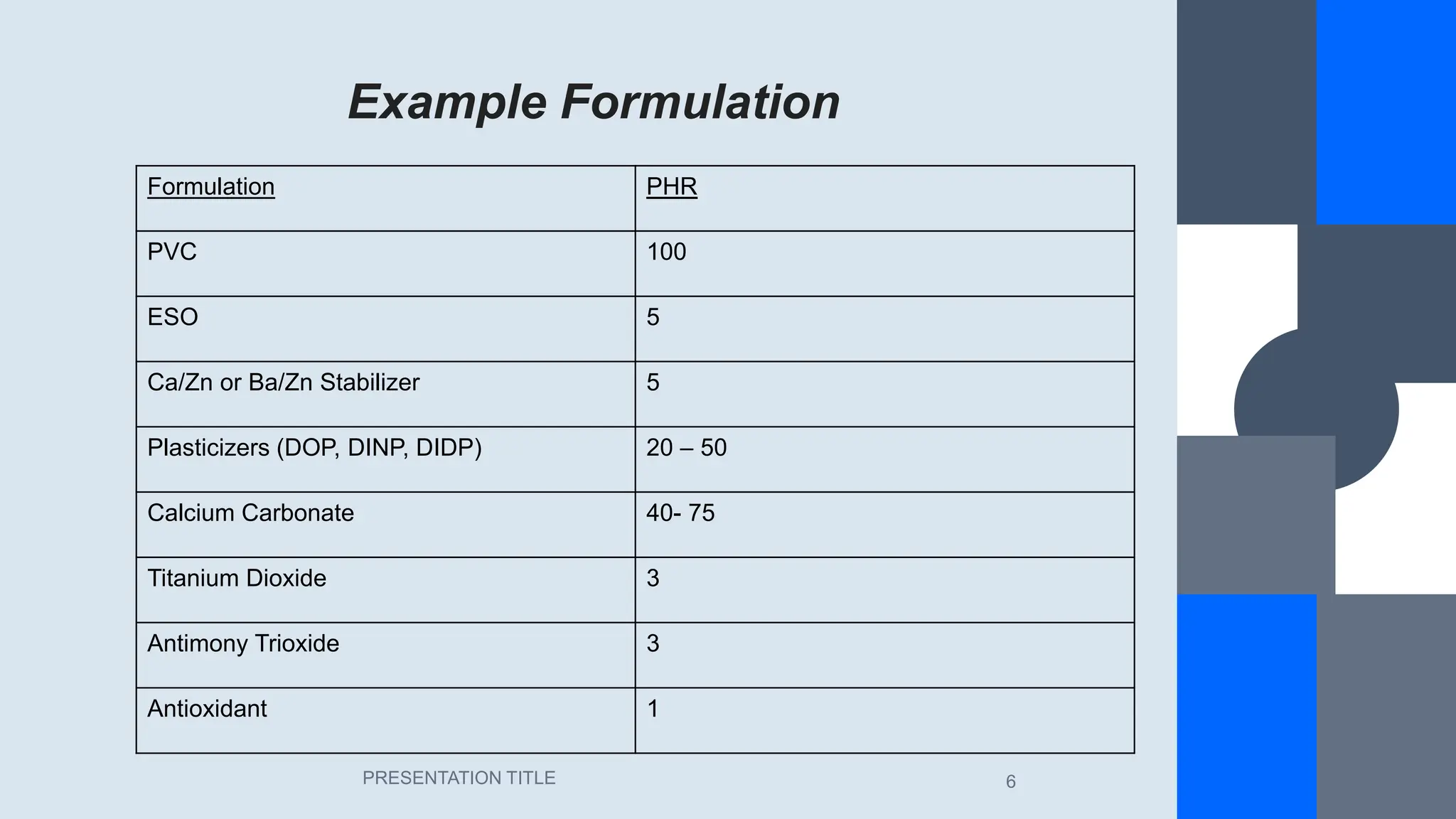

The document discusses the formulation and properties of polyvinyl chloride (PVC) compounds used for electrical wiring and cables. It describes the typical components of a PVC insulation or jacket compound, including PVC resin, plasticizers to increase flexibility, fillers like calcium carbonate, pigments, stabilizers, and additional additives. Common plasticizers used are phthalate esters like DOP, DINP and DIDP. The compounds provide insulation, are resistant to chemicals and weathering, and can be flame retarded. PVC is widely used for its electrical and physical properties in applications like low voltage wire, telecommunication lines, and automotive wiring.