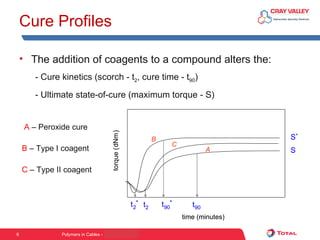

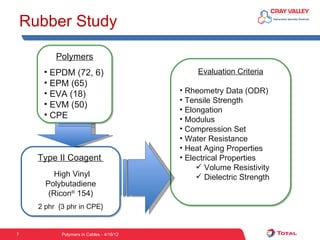

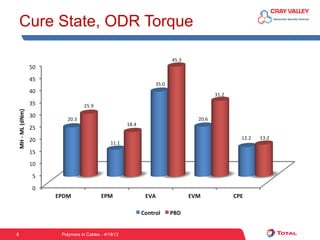

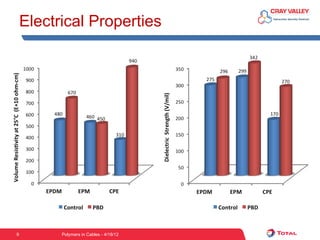

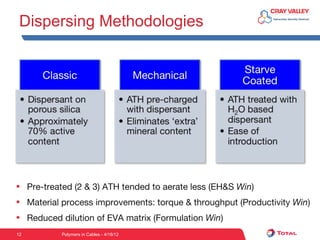

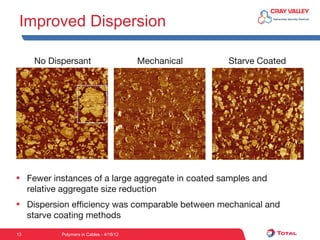

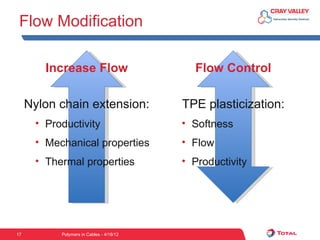

The document discusses advancements in wire and cable polymers, focusing on coagents that enhance curing performance and optimize flow and processibility. It categorizes coagents into Type I and Type II, detailing their effects on cure kinetics and ultimate state of cure in various polymer systems. Additionally, it covers applications in high-temperature environments, dispersion methodologies, and improvements in electrical properties and flammability performance.