The document discusses pump testing standards and their impact. It provides an overview of the ANSI/HI 14.6-2011 standard for pump acceptance testing. It explains that tolerances are needed because no pump is perfectly manufactured and tests have variability. It reviews previous standards and how they compare to the new HI 14.6-2011 and ISO 9906-2012 standards, noting the new standards allow specifying a power or efficiency tolerance. It provides default acceptance grades for different applications and discusses ensuring the supplier specifies which standard a pump curve or test is based on.

![Making Sense of Pump Testing Standards: How understanding standards can impact the bottom line

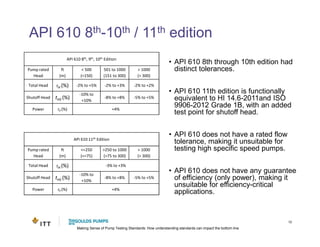

HI 1.6-2000 level B to HI 14.6-2011

10

• There is no close equivalent of Level B

in the new standard.

• You need to pick the grade that best

meets your needs.

Pump

rated Head

ft

(m)

< 200

(<60)

< 200

(<60)

200 to 500

(60 to 150)

>500

(>150)

Pump

rated Flow

gpm

(m3/h)

0 to 2999

(0 to 680)

>=3000

(>=681)

All

Total Head tH (%) -3% to +5% 0% to +3%

Rate of

Flow

tQ (%) -5% to +5%

Efficiency t (%) - 100/[(120/ηp)-0.2]%

??

Test

Parameter

Guarantee

Requirement

Grade Grade 1 Grade 2 Grade 3

∆tQ 10% 16% 18%

∆tH 6% 10% 14%

Acceptance Grade

Symbol 1B 1E 1U 2B 2U 3B

Rate of

Flow

Mandatory tQ (%) ± 5% ± 5% 0% to +10% ± 8% 0% to +16% ± 9%

Total

Head

Mandatory tH (%) ± 3% ± 3% 0% to +6% ± 5% 0% to +10% ± 7%

Powera

Optional

(either/or)

tP (%) +4% +4% +10% +8% +16% +9%

Efficiencya t (%) -3% -0% - 0% -5% -5% -7%](https://image.slidesharecdn.com/12988pumptestingwebinar10-131124203425-phpapp02-160601110929/85/Pumps-Testing-10-320.jpg)