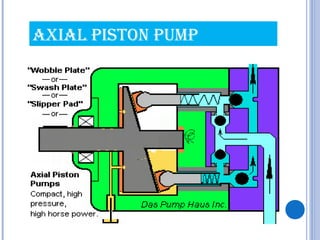

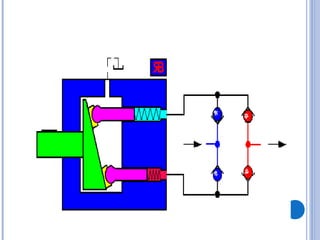

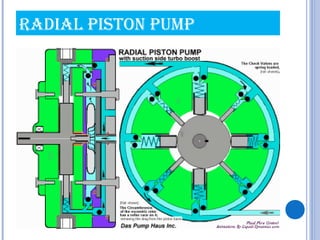

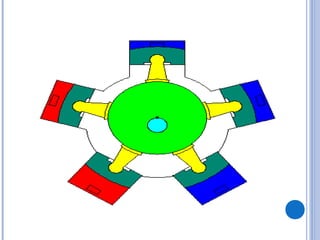

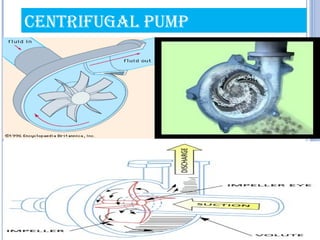

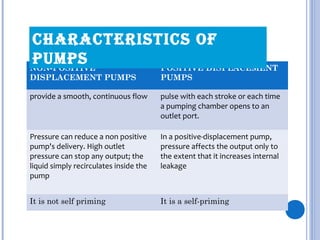

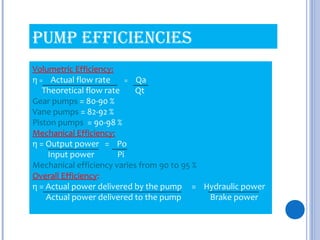

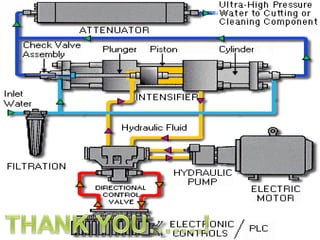

This document discusses different types of pumps, including their classifications, characteristics, applications, and performance. It describes hydrodynamic/non-positive displacement pumps, which use flow to transfer fluid at relatively low pressure and are generally used for low pressure, high volume applications. It also describes hydrostatic/positive displacement pumps, which have close-fitting components and can create pressure to transfer fluid in fixed or variable amounts. Specific positive displacement pump types discussed include gear pumps, vane pumps, piston pumps, and their common applications in industries like chemicals, food processing, and marine. Pump performance factors like volumetric efficiency, mechanical efficiency, and overall efficiency are also covered.