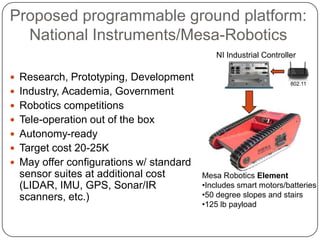

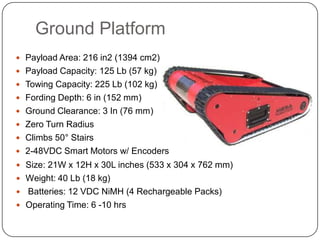

The proposed programmable ground platform by National Instruments and Mesa Robotics aims to facilitate research, prototyping, and development in robotics across various sectors. It features autonomy-ready capabilities, standard sensor suites, and robust hardware specifications while targeting a cost of $20-25k. The platform is designed to accommodate payloads, operate on diverse control systems, and navigate challenging terrains, making it suitable for robotics competitions and tele-operation.