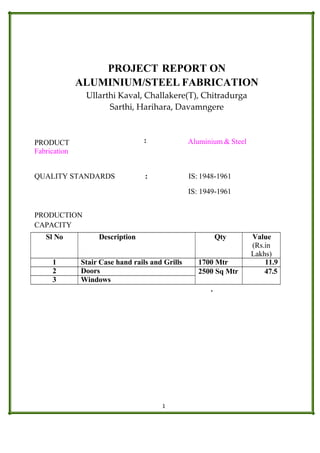

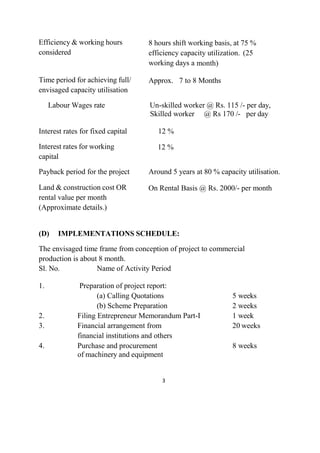

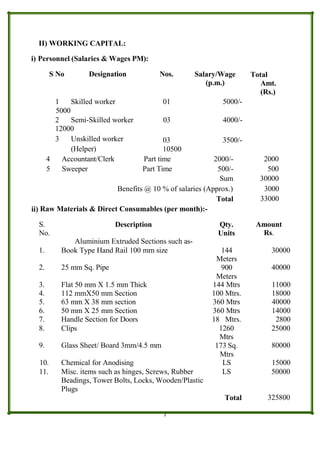

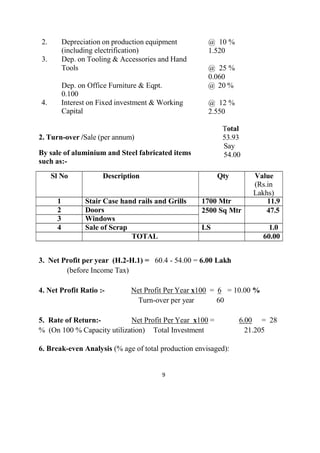

This project report summarizes a proposed aluminium and steel fabrication business. The business will produce items like doors, windows, staircases, handrails, and supports. It will have an annual production capacity of 1700 meters of staircases and handrails, 2500 square meters of doors, and an undisclosed quantity of windows. The total annual sales are estimated to be 60 lakhs rupees. The total capital investment is estimated at 26.73 lakhs rupees with fixed capital of 15 lakhs rupees and working capital of 11.73 lakhs rupees. The business is projected to earn a net annual profit of 6 lakhs rupees at 80% capacity utilization