The document provides details about a final project report on an automatic spray painter using a 2-DOF robotic arm. It includes the names and enrollment numbers of the 4 students on the project team. It discusses the external and internal project supervisors. It also includes acknowledgments thanking various people who provided guidance and support. The document is divided into multiple chapters that discuss processes automation, analysis and simulation, implementation proposals, the mechanical structure, and conclusions from the project.

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

4

1.1 INTRODUCTION

This chapter deals with detail concept about industrial automation and

robotics. This chapter concern with basic concepts about our task and type of robot

selected for our project and type of joint used in it. Detail Block diagram and

general schematics are also discussed with type of digital controller used. After

going through this chapter readers find them selves well aware about automation

and robotics and about our project.

1.2 Automation and Robotics

Automation is the use of electrical, hydraulic or pneumatic power to move stage

machinery, staging, performers or scenery. The effectiveness of any automation

system depends entirely on the quality of its underlying electrical, mechanical and

control engineering. As computers have changed all aspects of the entertainment

industry so the advances have revolutionized automation making sophisticated

effects ever more widely available. Both in a performance environment and as part

of the supporting infrastructure, the uses and advantages of automation are

manifold. [25]

1.2.1 Advantages of Automation

Absolute control of speed and position Repeatability of moves

1. Coordinating multiple piece moves

2. Offline editing and simulation

3. Moving pieces in complicated paths

4. Reduced manual handling

5. Repeating moves indefinitely

6. Automatic safety checking

7. Improved efficiency

8. Safe movement of a single piece controlled by

9. several motors

10. Movement in confined spaces](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-12-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

5

1.2.2 Robotics: Flexible Automation

Most manufacturing automation is called fixed automation. A stamping

machine can stamp only one kind of sheet metal part without being retooled, for

example, or a boring machine bores only one kind of hole in one kind of part.

When robots are part of an automatic process, the process can be changed by

changing the programming of the robots. Robotic automation is called flexible

automation [28].

1.2.2.1 Definition of Robot

Robots are more and more used in industrial and commercial applications.

Now, the number of robots in use is increasing at the rate of about 35% per year.

Sales volume is also increasing at the same rate.

Some of the reasons for the increased use of robots are as follows:

Reduced Production Cost.

Increased Productivity.

Improved Product Quality.

Operation in Hazardous and Hostile Environment.

Improved Management.

Decreased Reaction and Debugging Time

A robot is an autonomous artifact that obtains information by sensing the world

around it and uses the information to manipulate its environment to achieve goals.

Robot sensing includes vision, sound, touch, and others. Manipulation includes the

use of specialized tools and dexterous manipulation. Robots often have the ability

to change their locations in the world (locomotion).](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-13-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

8

robotic disciplines. Realizing the fullest capabilities of robots will require speech

understanding and common sense reasoning. For a robot to communicate with

people, it will require to have understanding of the world, or at least understanding

of its domain environment. Research projects to achieve this goal have been

underway at universities for many years [28].

1.3 PROJECT DESCRIPTION

Our Project named “Automatic Spray Painter By Articulated 2DOF-

Robotic Arm” is the implementation of theoretical concepts of Modern Control

System. This Project is related with Automation and Robotics (as a Linear System)

theory in Laboratory conditions.

The theme of this Project is to Design 2 Degree of Freedom Robotic Arm

Control in which 2DOF Control will be:

1) Yaw Control of Shoulder.

2) Pitch Control of Elbow.

All of these Controls will be Servo Mechanism based. The Controls of this

system is based on Linear Control system (as some of Robotic Arm Control

System considered as Non-Linear) and is an application of Inverted pendulum. The

End Effecter of this System is Nozzle connected with small compressor (filled with

color) through thin rubber pipe. Flow control of color from Nozzle is through

Servo control Valve. The Work space is Thin Metal Plate of specific Dimensions.

Our goal is to Design Economical, Light Weight, Reliable System which

could be useful for future students to work with this system to achieve more

achievements in Automation & Robotics field.

.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-16-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

13

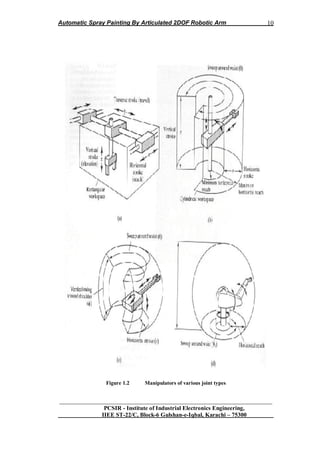

1.3.6 Joint selected for the task

1.3.6.1 Articulated Arm Manipulator

The common industrial manipulator is often referred to as a robot arm, with

links and joints described in similar terms. Manipulators which emulate the

characteristics of a human arm recalled articulated arms. All their joints are rotary

(or revolute). Representative articulated manipulators are the ASEA robot

1.3.6.2 Degree of freedoms

The motion of articulated robot arms differs from the motion of the human

arm. While robot joints have fewer degrees of freedom, they can move through

greater angles. For example, the elbow of an articulated robot can bend up or down

whereas a person can only bend their elbow in one direction with respect to the

straight arm position. Many applications do not require arms with articulated (or

revolute) geometries. Simpler geometries involving prismatic or sliding joints are

often adequate. Prismatic and revolute joints represent the opposite extremes of a

universal screw. In a revolute joint, the screw pitch is zero, constraining the joint to

pure rotation. In a prismatic joint, the pitch is infinite, constraining the joint to pure

sliding motion. Revolute joints are often preferred because of the strength, low

friction and reliability of ball bearings. Joints that allow a combination of

translation and rotation (such as lead screws) are not normally used to join the

links of robot arms [29].

1.3.6.3 Work space consideration

Workspace considerations, particularly reach and collision avoidance, play an

important part in the selection of a robot for an application. All manufacturers give

detailed specifications of the work space of their robots and associated equipment.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-21-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

14

1.3.7 SCARA Robot

Consideration of the motions involved in assembly has led to the

development of simpler arm geometry for use in assembly applications, known as

the SCARA (Selective Compliance Automatic Robot Arm) geometry. While all

SCARA robots have the same geometry the name SCARA does not have a

geometric basis. Most assembly operations involve building up the assembly by

placing parts on top of a partially complete assembly. A SCARA arm has two

revolute joints in the horizontal plane, allowing it to reach any point within a

horizontal planar workspace defined by two concentric circles. At the end of the

arm is a vertical link which can translate in the vertical direction, allowing parts to

be raised from a tray and placed on to the assembly. A gripper placed at the end of

this link may be able to rotate about the vertical axis of this link, facilitating

control of part orientation in a horizontal plane. One problem in achieving

spherical wrist design is the physical difficulty of fitting all the components into

the available space. The size of the human wrist is small because the muscles

which power it are located in the forearm, not in the wrist. Wrist design is a

complex task, involving conflicting goals. Desirable features of a wrist include

[29]

Small size

Axes close together to increase mechanical efficiency

Tool plate close to the axes to increase strength and precision

Soluble mathematical model

No singularities in the work volume

Back-driving to allow programming by teach and playback

Decoupling between motions around the three axes

Actuators mounted away from the wrist to allow size reduction

Paths for end effectors control and power through the wrist

Power proportionate to the proposed task

Rugged housing.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-22-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

16

1.4.2 Controller

Every robot is connected to a controller (usually a microcontroller), also it

can be connected to a simple home PC, which keeps the pieces of the arm working

together. The controller functions as the "brain" of the robot. Robots today have

controllers that run programs. Usually, entirely pre-programmed by people, robots

have very specific jobs to accomplish.

In the block diagram representation of Robotic Arm system there are three

separate servo- Control systems(feedback control loops) due to the fact that

physics involve in system dynamics(motor as an actuator) in Robotic Arm is on the

concept of “Absolute Frame of Reference “. So, three separate Feedback control

loops are drawn having digital input through digital computer with designed

sampled time “T” having switching sequence between loops as desired.

Digital controllers are of “ON-OFF type” for shoulder, elbow and valve

dynamics which are Plants of the system. Feedback sensor is position sensor and is

part of Servo motor by combining called Servomechanism. TL is the Load Torque

on joints due to Actuation Mechanism involving gear & belt system. D/A converter

is to convert discrete signal in to Continuous time signal and A/D converter is to

convert Continuous time signal in to Discrete signal [12].

1.4.3 Robotic Arm

Robotic arms come in all shapes and sizes. The arm is the part of the robot

that sets the end- effectors and sensors to do their preprogrammed job. Many (but

not all) resemble human arms and have shoulders, elbows, and wrists, even fingers.

Each joint gives to the robot one degree of freedom. So, a simple robotic arm with

three degrees of freedom could move in three ways: up and down, left and right,

forward and backward.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-24-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

17

1.4.4 Actuation System and Drive

The drive is the engine that drives the links (the sections between the joints)

into their desired position. Very common devices that robots use as drives are

Servomotors and Step-Motors. These two categories are usually connected directly

to a microcontroller. The microcontroller triggers them by generating specific

pulses. They are very useful because they have flexible moving and opposed to the

simple motors they can be set at very specific positions each time. Also, a

characteristic that makes them useful for robots is that they can handle with heavy

items. In other words these kinds of motors can carry heavy parts [15].

1.4.5 End-Effectors

The end-effectors is the "hand" connected to the robots‟ arm. It could be a

tool such as a gripper, tweezers or a scalpel. So, the end-effectors are the part of

the robotic system that characterizes its implementation.

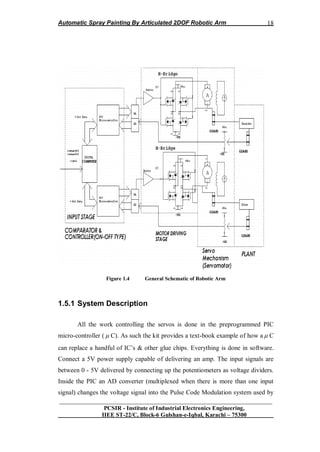

1.5 OVER ALL SYSTEM

Over all system is represented by General Schematics. The General

Schematics of the system have four parts. First part is Comparator and Controller

part which is digital controller (ON-OFF type). Comparison and Controller is done

by using PIC microcontroller. Second part of the system is motor driving stage

consist of H-bridge for bidirectional switching of system. Third stage is servo

mechanism consist of Servo motor with gear system. The last stage is the Plant

which of course Arm Manipulator. General Schematic of system is shown in

figure 1.4.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-25-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

19

servo motors. This signal is a 5V pulse between 1 and 2 mSec long repeated 50

times per second. That is, a 20msec frame rate.

The width of the pulse determines the position of the server. Most servos

will move to the center of their travel when they receive a 1.5msec pulse. One

extreme of motion generally equates to a pulse width of 1.0msec; the other extreme

to 2.0msec with a smooth variation throughout the range, and neutral at 1.5msec.

The period between the pulses is used to synchronize the receiver. Servos are

closed loop devices. They are constantly comparing their position (proportional to

the pulse width) to their actual position (proportional to the signal voltage input.) If

there is a difference between the two the servo electronics will turn the motor to

adjust the difference error. This also means that servos will resist forces which try

to change their position. When a servo is not receiving positioning pulses (i-e not

being provided with power) the output shaft can be easily turned by hand. [18]

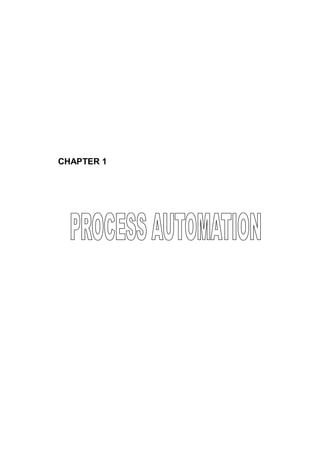

1.5.2 Electronics

To guide the servomotors on when and how to move, an electronic board is

needed. On the board (Figure 1), there are some electronic circuits that give to the

preprogrammed microcontroller the ability to communicate with the peripheral

devices (servomotors, sensors, PCs). The board has inputs and outputs that are

connected to the microcontroller. Four outputs are used for the servomotors and

one input for the sensor. One I/O interface based on a DB-9 RS-232 is used for

transferring data from and to a PC when connected. The microcontroller is a PIC

model 16F877A (Microchip). PIC has 13 I/O pins, an 8-bit microprocessor and 1K

of RAM. Its circuit is a usual TTL/CMOS based and so its V is +5V. Using the

PWM (Pulse Width Modulation) technique, PIC controls the servomotors. Also

PIC inputs receive signals that come from sensors and may be useable at any case.

In our work we use a supersonic sensor, which transmits high frequencies and then

receives the reflections. In this way PIC can understand where and in which height

a CD is, related to the ground. The board may also communicate with other

external sensors via the PC interface (for sensors connected on the PC) or get](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-27-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

20

connected with more sensors attached to the board directly via its integrated

sockets (PIC16F877 Tutorial and basic explanations; Microchip PIC16F877A

Technical Specifications 2002; PIC16F877 Fundamentals and Programming

Examples; Programming the PIC16F877 Micro Controller and Data Sheets

Resource Centers Internet Sites).

1.5.3 Assembly

Check the components in the kit against the Components List. Some of the

resistors stand up on the board. Make sure to get the electrolytic capacitor and the

IC1 around the correct way. To complete the kit between 5K - 10K potentiometers

are required to produce the input signal. Connect each pot as a voltage divider with

the center pin going to the signal input. Servo motors are required. They have not

been included in this kit because users will usually have their own particular servos

they wish to control.

1.5.4 Servo Motor

Servo is a small device that has an output shaft. This shaft can be

positioned to specific angular positions by sending the servo a coded signal. As

long as the coded signal exists on the input line, the servo will maintain the angular

position of the shaft. As the coded signal changes, the angular position of the shaft

changes. In practice, servos are used in radio controlled airplanes to position

control surfaces like the elevators and rudders. They are also used in radio

controlled cars, puppets, and of course, robots [20].](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-28-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

23

R2 is any small resistance (10-300 ohms). Q1 is a very common type of transistor:

a 2N2222. See part list for a drawing of these, and this for a picture. A transistor

costs no more than 50 cents.

In order to control bi-directional a motor (ON/OFF, and clockwise or

counterclockwise), a H-type circuit is needed. In the second picture, if both upper

left and lower right transistors are ON, the current will flow through the motor

from left to right, yielding a CW rotation.

Trouble is that there is a lost of power. I have not been able to sink more than 500

mA through the motor in the H circuit. It is enough for small motors, but not for

the Lego-type motors who need a full 1 ampere of current.

One alternative is to replace transistors with power-MOSFET. I haven't try,

but you might look at MOSFET H-Bridge Schematic & Theory of Operation for

more. Another alternative that I explored in tutorial 2 is to use a mechanical switch

to control the direction of motion. Relays are electro-magnetic switch that can be

controlled easily with a transistor. Since the current is independent of the

transistor-magnet circuit, there is no lost of power [25].

1.7.2 Communication port

Personal computer needs to communicate to the controller. The two likely

methods are to use the ports available. There is two kind of port. The parallel port

(or printer port) is easy to program, but has a limited capacity at any given time. In

the best case, it can only output 8 bits of information, and can input from sensor 8

bits.

There is a large variety in sensors, ranging from electronic thermometer to

pressure sensors. The simplest kind is the on/off sensors. When pressure is applied,

the switch turns on. One bit of information is enough per sensor.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-31-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

24

1.7.3 Sending Command/Receive Data

The first layer is only a list of what can possibly be done with your robot.

Now we need to send specific commands to your robot. Commands can be very

simple, such as "Start motor 3 now", or more complex, such as "Start motor 3, wait

5 seconds, start motor 2, and when sensor 2 gets on, stop all moves." The VBASIC

interface that I proposed in another page is an example which can send only simple

commands. A better interface would accept commands such as "Turn motor 3 for x

seconds" or "Turn motor 3 until sensor 2 gets on".

1.7.4 Constrain Control

Not all moves are safe for the health of your robots. For example, turning

the arm to the left for an indefinite time is risky if your arm cannot do more than

360 degree turns (and most arms can not do that much).

In order to avoid wreckage, your robot should know things about its

limitations. These are called constraints. Example of constraints are:

If the base is turning for more than 5 seconds, then you ought to stop turning the

base.[25].

1.8 Summary

A basic of Robotic Arm is so important for every engineer to step in

Automation and robotics technology. Basic information provided in this chapter is

so helpful for the student of this level to design such type of manipulator on this

level that we proposed in this chapter. Type of block diagram, schematic, type of

controller etc is much helpful to collect idea for their designs.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-32-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

27

one DOF of each joint. As this system is one of many applications of Inverted

Pendulum so linear model of this system is established by study the dynamics of

Inverted Pendulum. Many of models of Robotic Arm system is based on nonlinear

system on undergraduate level which is due to lack of awareness of designing on

this level. Following mathematical modeling lead the undergraduate engineers to

aware the proper analyses of dynamics of robotic arm system by consider it as

linear system [27].

To analyze dynamics of arm manipulator, first analyze their Direct

Kinematics & inverse kinematics of joints moment, then analyze the Transfer

Function of whole system.

To analyze the kinematics of arm joints, it is important to analyze kinematics of

shoulder & elbow separately. For this first of all sum the forces perpendicular to

the shoulder & elbow.

Applying condition of equilibrium

For Shoulder joint

1 1 1

J

For Elbow joint

2 2 2

J

Solving the systems along these axis ends up saving lot of algebra.

You should get the following equations [27].

For Shoulder

.. ..

1 1 1 1 1 1 1 1 1sin cos sin cosV H Mg ML M d (2.1)

For Elbow

.. ..

2 2 2 2 2 2 2 2 2 2 2 2 2sin cos sin cosV H m g m l m d (2.2)

Torque () on Shoulder joint](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-36-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

30

For Elbow

.. ..

2

2 2 2 2 2 2 2 2 2 2( )J m l m gl m l d (2.12)

The direct kinematics of the system is given as:

For shoulder

2 2 2

1 1 1 1( )J ML D MgL ML D d

Therefore time domain analysis of shoulder:

2 2

1 1

2

1

( ) ( )

( )

d t J ML D MgL

t MLD

(2.13)

For Elbow

2 2

2 2 2 2 2 2

2

2 2 2

( ) ( )

( )

d t J m l D m gl

t m l D

(2.14)

The above sets of equations for Elbow and shoulder represent the direct kinematics

of plant.

For inverse kinematics i.e. analyzing angular displacements of plants for given

space coordinate [27].

2.2.1 Actuation Mechanism

The actuation mechanism consists of belt & gear, driven by the DC motor

by which plant works (i.e. shoulder & elbow move).

So overall transfer function depends upon actuation mechanism will depend on

transfer function of DC motor, belt & external gear.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-39-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

31

2.2.1.1 Belt & Gear

Load inertial to the motor consists of gear (of radius „r‟) & masses of

shoulder (i.e. m1) & elbow (i.e. m2).

Therefore, Load Torque is given as;

For elbow joint system

1

2

1 1.LT Mr D

Or,

1

2 2

1 1. ( )LT Mr D t

For elbow joint system

2

2 2

2 2 2. ( )LT m r D t

2.2.1.2 Motor

Dynamics of motor will also affect the transfer function of the actuation

mechanism.

Experimentally, the transfer function of armature control servo dc motor is given

as, [27]

.

( )

( ) 1

m

m

Kt

E t D

(2.15)

Or,

( )

( ) ( 1)

m

m

Kt

E t D D

(2.16)

Where,

Km = Steady state gain in rad/s/v

τm = Time constant for motor in sec

Therefore, overall actuation mechanism is given as for shoulder & elbow,](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-40-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

32

For elbow joint system

2 2

1 1

1

( )

( ) ( 1)

m

m

K Mr Dt

E t D D

2

11

1

( )

( ) ( 1)

m

m

K Mr Dt

E t D

(2.17)

For elbow joint system

Similarly,

2

2 2 2

2

( )

( ) ( 1)

m

m

K m r Dt

E t D

(2.18)

Differential equation of overall system

For shoulder joint system

2 2 2

1 1 1 1

1

2

1 1

( )

( ) 1

m

m

J Ml D Mgl K Mr Dd t

E t Ml D D

2 2 2

1 1 1 1

1

1 1

( )

( ) 1

m

m

K Mr J Ml D Mgld t

E t Ml D D

2 22

1 1 111

2

1 1

( )

( ) 1

m

m

J Ml D MglK rt

E t l D D

(2.19)

For elbow joint system

2 22

2 2 2 2 222

2

2 2

( )

( ) 1

m

m

J m l D m glK rt

E t l D D

(2.20)

By inserting transfer function values from specification table; differential equations

are given as, [27]](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-41-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

33

For shoulder joint system

2

1

1

( ) 21.4

0.2

( ) 5.52

t D

E t D D

(2.21)

For elbow joint system

2

2

2

( ) 20.7

0.076

( ) 5.52

t D

E t D D

(2.22)

Transfer function for Shoulder joint system,

2

1

2

1

( ) 0.2 4.28

( ) 5.52

s s

E s s s

(2.23)

Transfer function of Elbow joint system,

2

2

2

2

( ) 0.076 1.55

( ) 5.52

s s

E s s s

(2.24)

2.3 Stability of Open Loop System

In the light of mathematical model and transfer function in s-domain in

section 2.2. The next step towards designing of system is the analysis of its

stability. There are two ways of analysis. First by mathematical way and second

one is by computer simulation which is actually confirmation of mathematical way

of analysis.[2]

It is clear from the above roots of the system that system is marginary

stable in open loop that one of its pole lie at origin while others are at the left side.

Let the stability of system be analyzed by evaluating d(t) by applying

impulse at input i.e.

e(t) = σ(t)

Where, σ (t) = impulse input

From equation (2.23),

c(t) = 0 .775 – 0.575e-5.52t

(2.25)

Fort , c(∞) = 0.775

Above result clearly shows that system is not unstable in open loop and is

marginary stable for the roots mention above.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-42-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

34

It is clear from the above roots of the system that system is marginary

stable in open loop that one of its pole lie at origin while others are at the left

side.[2]

Let the stability of system be analyzed by evaluating d(t) by applying impulse at

input i.e.

e(t) = σ(t)

Where, σ (t) = impulse input

From equation (2.24),

c(t) = 0 .280 – 0.21e-5.52t

(2.26)

Fort , c(∞) = 0.280

Above result clearly shows that system is not unstable in open loop and is

marginary stable for the roots mention above.

Results from computer simulation clearly confirm the mathematics for

stability analysis for open loop system. Pole-Zero maps in figure 2.2 of the

Shoulder joint system clearly proves that system is marginary stable.

From equation (2.23) in section 2.2 roots for Shoulder joint system is given as,

z1= j4.63, z2= -j4.63, p1= 0, p2= 5.52

Pole-Zero Map

Real Axis

ImaginaryAxis

-6 -5 -4 -3 -2 -1 0 1

-6

-4

-2

0

2

4

6

p=5.52

p=0

z=j4.63

z=-j4.63

Figure 2.2 Pole-Zero Map of Shoulder Joint](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-43-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

37

Impulse response of the shoulder joint system is shown in figure clearly

shows that response of the shoulder joint system is settled down proves the

analysis in section 2.3.2

2.4 Kinematics of Robotic Arm

Robotic arms are common place in today's world. They are used to weld

automobile bodies, employed to locate merchandise in computerized warehouses,

and used by the Space Shuttle to retrieve satellites from orbit. They are reliable and

accurate. This reliability and accuracy is due to the computer a robot arm uses in

determining where and how it should move. This control computer is programmed

with some basic mathematics. In this paper, we will look at the mathematics

behind robot arms [21].

We will study the two-link robot arm shown in Figure 2.6

Figure 2.6 Two-Link Robotic Arm

Let, θ1 =A and θ2 =B

Most robot arms are more complicated than this, using three links and a

moveable "hand," but with these complications come much more difficult

mathematics. Operation of the two-link arm is simple. The first link (length L1)](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-46-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

38

pivots around the origin of an XY Cartesian coordinate system while the second

link (length L2) pivots about the connection between the two links. The two pivot

points are drawn as circles. The angle the first link makes with the horizontal (X)

axis is designated A, while the angle the second link makes with the first link is

designated B. The end of the second link is the position of the robot arm, (X, Y).

Arm position (X, Y)? This is simple trigonometry. The second problem is

"inverse kinematics." Here, we want to ask: given the position (X, Y), what angles,

A and B, yield this position? This is a more difficult problem. Lastly, we need to

look at the problem of "trajectory planning." In trajectory planning, we ask: given

our current position (X, Y) and some desired new position, how do we change the

angles A and B to arrive at this new position? We examine each of these problems

separately, using the two-link robot arm [21].

2.4.1 Forward Kinematics

The kinematics problem requires computation of the robot arm Cartesian

position (X, Y), knowing the two link angles, A and B. Referring to Figure 2.6

We can see the position of the end of the first link (X1, Y1) is given by

X1 = L1 cos (A)

Y1 = L1 sin (A)

Then, the end of the second link (X, Y) is simply

X = X1 + L2 cos (A + B)

Y = Y1 + L2 sin (A + B)

Combining these two sets of equations provides the solution to the

kinematics problem:

X = L1 cos (A) + L2 cos (A + B) (2.27)](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-47-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

39

Y = L1 sin (A) + L2 sin (A + B) (2.28)

An interesting question at this point is: if we cycle A and B through all possible

combinations (-180 degrees < A < 180 degrees, -180 degrees < B < 180 degrees),

what would the region of coverage look like? If L1 and L2 are equal, the region

would be a circle (radius L1 + L2). If L1 and L2 are not equal, the region would be

armular (like a donut). This coverage region becomes important in the inverse

kinematics problem, where we need to know if it's possible to reach a given point

by adjusting the link angles.

2.4.2 Inverse Kinematics

The kinematics problem is seen to be fairly easy to solve. The inverse

problem, that of finding A and B, knowing (X, Y) is not nearly as simple. Let's see

why. [21]

Figure 2.7 Inverse Kinematics

Using the kinematics equations, if we know X and Y, we need to solve the

following for A and B:](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-48-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

40

L1 cos A) + L2 cos (A + B) = X (2.29)

L1 sin (A) + L2 sin (A + B) = Y (2.30)

This is a nonlinear problem. There are two possible solution approaches:

algebraic and geometric. The algebraic approach (solving the equations directly) is

tedious and involved. For the two-link robot arm, the geometric approach is more

straightforward. We will outline the steps of the algebraic approach to illustrate

some salient points of the inverse kinematics problem. Also, by outlining these

steps, we allow the more industrious reader to see if he/she can solve the problem

algebraically. After this outline, we will develop the solution to the problem with a

geometric approach.

2.4.3 Algebraic Solution

In the algebraic solution, we first square both of the above equations and

add them together. Then, we apply these trigonometric identities: [21]

Cos (A + B) = cos (A) cos (B) – sin (A) sin (B)

Sin (A + B) = cos (A) sin (B) + sin (A) cos (B)

sin2

(C) + cos2

(C) = 1

Where C is any angle

Following these steps, we are able to obtain a relation for cos (B) simply in

terms of X, Y, L1, and L2. That relation is (see if you can find it)

Cos (B) = (X2

+ Y2

– L1

2

- L2

2

)/2L1L2 (2.31)

With this, we can find B by applying the inverse cosine, or can we? What if

cos (B) is greater than one or less than minus one? In these cases, there is no

solution! When this happens, the desired point (X, Y) is not within the coverage

region of the robot arm (as discussed in the previous section). If (X, Y) is in the](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-49-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

41

coverage region, can we find a unique B? No, just knowing the cosine is not

sufficient. If B is a solution to the above equation, so is -B since

Cos (B) = cos (-B)

Hence, the inverse kinematics problem always has two solutions. This is

shown in Figure 2.7. In "robotics talk," one solution is referred to as "elbow-out"

and one is "elbow-in." To specify which solution we want, we must also find the

sine of B.

Knowing the cosine of B, the sine is given by

Sin (B) = + [1 - cos2

(B)] ½

(2.32)

The angle B is then completely specified by selecting either a plus or minus

sign in this expression. The robot designer must decide which sign to choose based

on problem geometry and current arm configuration. This choice is discussed in

detail in the "Trajectory Planning" section. Figure 2.8 shows the Cartesian

quadrant in which an angle belongs, based on the sign of the two trigonometric

functions.

Figure 2.8 Quadrant System](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-50-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

42

At this point in the algebraic solution process, we have the angle B. How

do we find A? Knowing B, and hence sin (B) and cos (B), we substitute this (along

with X and Y) back into the kinematics equations. Using the relations for the sine

and cosine of the sum of two angles, the resulting equations will be (again, see if

you can get these)

[L1 + L2 cos (B)] cos (A) – L2 sin (B) sin (A) = X (2.33)

L2 sin (B) cos (A) + [L1 + L2 cos (B)] sin (A) = Y (2.34)

Here, we have two linear equations with two unknowns: sin (A) and cos (A).

Solving these equations (use Cramer's rule) and applying the angle

convention in Figure 2.8 will yield a unique value for A. At this point, we have

solved the inverse kinematics problem with an algebraic approach.

2.4.4 Geometric Solution

The geometric solution is more direct. We can develop expressions for the

angles A and B by simply looking at the geometry of the problem. First, we'll find

B. Figure 4 sketches the configuration necessary for this evaluation. If we look at

the triangle formed by the two links and the line [of length (X2

+ Y2

)1/2

] connecting

the origin to the point (X, Y), we can use the law of cosines to write [21]

X2

+ Y2

= L1

2

+ L2

2

- 2L1 L2 cos (180º - B) (2.35)

But, cos (180º - B) = -cos (B). Substituting this into the equation and

solving for cos (B) yields

Cos (B) = (X2

+ Y2

- L1

2

- L2

2

)/2L1L2 (2.36)](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-51-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

43

This is exactly the result obtained using the algebraic approach. The

geometric approach is seen to be much simpler. Recall, though, that this does

define a unique angle B. This definition is made by establishing a value for sin (B),

as outlined in the algebraic approach.

The other angle, A, is found with a two step procedure. If we define the

angle between link 1 and the line [length (X2

+ Y2

)1/2

] from (0, 0) to (X, Y) as C

(see Figure 2.9).

Figure 2.9 Geometric solutions for angle A

We can write

Sin (C) = L2 sin (B)/(X2

+ Y2

)1/2

(2.37)

Cos (C) = [L1 + L2 cos (B)]/(X2

+ Y2

)1/2

(2.38)

These expressions define a unique C. Now, using the right triangle (Figure

2.9) defined by the three coordinates (0, 0), (X, 0), and (X, Y), we have](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-52-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

45

change A first, B first, or both simultaneously? In which direction do we change

them? Clockwise? Counterclockwise? This is not a difficult problem if there are no

obstacles in the path of the robot arm, i.e. we have complete freedom of

movement. In that case, we usually move A and B in the direction of smaller

change. That way, we minimize the energy required to move the arm and the time

required to change configuration. [21]

As an example, look at Figure 2.11(a).

Figure 2.11(a): Graph-I

Here, L1 = L2 = 3, Aold = -45 degrees, and Bold = 90 degrees, which

corresponds to a Cartesian location of (Xold, Yold) = (4.24, 0). Check the math using

the kinematics equations. Say we want to move to (Xnew, Ynew) = (-4, 4). To reach

this point, the inverse kinematics equations yield Anew = 115 degrees, Bnew = 39

degrees (see if you can get the same values - I have rounded to the nearest degree).

We'll assume we can only change the angles one at a time. So, to go from (4.24, 0)

to (-4, 4) with minimum angle change, we swing A from -45 to 115 degrees

(counterclockwise) and then B from 90 degrees to 39 degrees (clockwise), as

shown in Figure 2 11(a). What if there was a solid wall in the quadrant where X >

0 and Y > O? In that case, the trajectory in Figure 2.6(a) would not be possible?](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-54-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

47

Figure 2.12(a): Path Followed By Two-Link Robot

The path is not a straight line due to the nonlinearities of the robot arm and

the motions as the angles are changed sequentially. If we changed the angles

simultaneously, the path followed would be much smoother. We can extend this

procedure to follow any desired trajectory. This allows us to get around any

obstacles that might be in the way of the arm. Simply draw the desired path and

compute Cartesian points along the path, along with the corresponding joint angles.

Then, cycle through each pair of A and B values until the endpoint is reached.

Figure 2.12(b) shows the arm following a three-segment straight line path from

(4.24, 0) to (-4, 4). Again, this path would be smoother if the angles changed

simultaneously. [21]](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-56-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

50

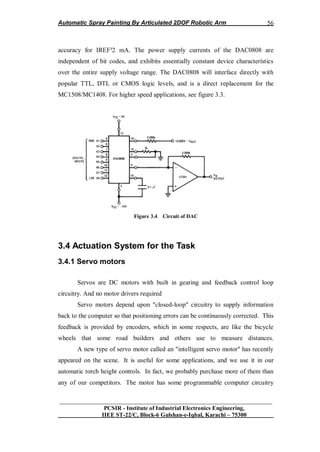

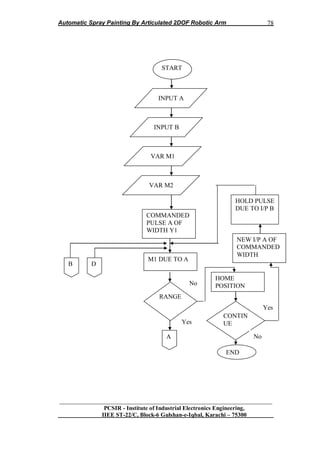

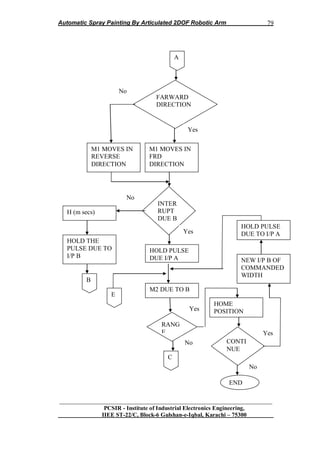

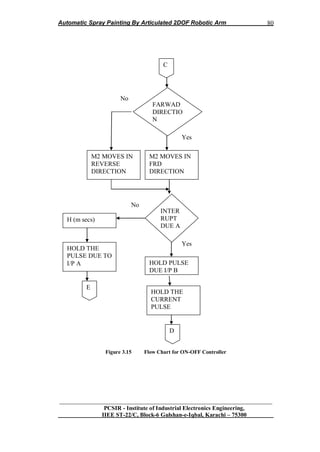

3.1 INTRODUCTION

This chapter contain practical design implementation of digital controller

for each joint and concept of difference equation. Transient response is also

discussed in detail by using MATLAB. Hardware design is also presented in this

chapter contain specification table and three dimensional views of different part of

designed manipulator. Software section is also discussed contain algorithms and

Flowcharts for each joint controller and also for master controller.

Robotic Arm System is represented by blocks in figure 3.1 consists of four

parts named Sensory System, controller and Electronics, Actuation System and

Manipulator Joints as plant.

Figure 1.1 Manipulation Systems

3.2 Sensory System of Robotic Arm

Sensors are the sensory system of a robot much like the five senses that

humans have: touch, sight, sound, smell and taste and measure environmental data

like touch, distance, light, sound, strain, rotation, magnetism, smell, temperature,

inclination, pressure, or altitude. Sensors provide the raw data that must be

processed to provide information to allow the robot to appropriately respond to its

environment. Robots are equipped with sensors so they can have an understanding

of their surrounding environment and make changes in their behavior based on the

information they have gathered. [24]

Sensors allow robots to detect objects and variations in the environment. A

robot will invariably be equipped with a number of sensors which may include: an

acoustic sensor to detect sound, motion or location, infrared sensors to detect heat

Sensory

System

Controller

&

Electronics

Electro-

Mechanical

Actuator

Plant

Manipulator

Joints](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-60-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

51

sources, contact sensors, tactile sensors to give a sense of touch, or optical/vision

sensors. A robot can also monitor itself with sensors.

3.2.1 Common Sensors for Manipulators

3.2.1.1 Touch Sensors

Touch sensors are basically variable switching devices that work through

pressure.

3.2.1.2 Global Positioning Systems

Global Positioning Systems (GPS) receive signals from orbiting satellites

that pinpoint the location of an outdoor robot on the Earth. [24]

3.2.1.3 Light Sensor

It measures the level of light as a number between 0% (total darkness) and

100% (very bright). Can differentiate light levels reflected from bright and dark

surfaces. Inside the light sensor is a photo-transistor. The photo-transistor acts like

a valve for electricity. The more light energy it senses, the more electricity

flows.[24]

3.2.1.4 Rotation Sensor

It measures the rotation of an axle or shaft. The rotation sensor sends out a

series of voltage pulses. There will be a number of pulses per rotation. In the lego

robotics kits there are 16 of these pulses per one revolution. These pulses are also

referred to as “ticks”, “clicks”, or “counts”.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-61-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

52

3.2.2 Sensor Selected for the Task

Rotation sensors (also called encoders) measure the rotation of a shaft or

axle. They are used to measure the angle of a robotic arm, or how far a mobile

robot‟s wheel has turned. [24]

3.2.1.1 Rotation Sensor

It measures the rotation of an axle or shaft. The rotation sensor sends out a

series of voltage pulses. There will be a number of pulses per rotation. In the lego

robotics kits there are 16 of these pulses per one revolution. These pulses are also

referred to as “ticks”, “clicks”, or “counts”.

Figure 2.2 Series of Voltage pulses

3.2.1.2 Pull to Position

In the case of autonomous mobile robots operating in unstructured

environments the position, geometry and orientation of objects of interest are not](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-62-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

53

known. We aim to use sensor inputs from targets directly to control the motion of

the robot and thereby use the world and its objects as its own best model. The robot

arm structure, dimensions and joint angles, however, are well known and so can be

used for control.

The approach used here is to develop a simple structured linked model of

the articulated limb. The model records link lengths, joint angles and joint

stiffness. The model is manipulated to 'pull' the end of the limb towards the desired

destination position and orientation. The direction of this pulls being derived from

robot sensors. Then the actual motion is realized by driving the joints and linkages

through the trajectories followed by the model. By incorporating continuous

sensory feed-back of joint angles and deriving updated target vectors from target

sensors very simple limb models are sufficient for the control task. Simply 'pulling'

the limb end point [24] towards the destination entails a simple vector mapping

(figure 3.1). Employing servo control of motion direction rather than position

means that the limb will achieve the target point even with simplified modeling.

There is no med to accurately model linkage weights and friction. This control

approach could be considered to be a primitive version of the perception driven

control which living creatures can employ.

3.3 CONTROLLER AND ELECTRONICS

3.3.1 ON-OFF Controller

The controller is responsible to establish the link between computer

and the robot. The reason for that is that the computer outputs only a few mA, not

enough to start most motors. Therefore, a supply of power is usually appended to

the controller (a 9volts, 1A in the case of Lego motors which are simple DC

motors).](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-63-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

57

incorporated into it, which lets it independently follow simple instructions. It

works well with our torch height controls, due to their low torque demand. We

believe intelligent motors are impractical for driving a cnc machine, for reasons

given below.

The following paragraphs explain each of these types of motors in more

detail.

Figure 3.5 Torque-Speed Curves of Servo Motor

Servo motors are somewhat more expensive than steppers -- perhaps

double the price, or more. They are generally just as accurate, if maintained in a

proper state of tune, however they rely on encoders to provide positioning

information back to the computer. Thus the complexity of the system is at least

doubled, with no accuracy advantage, greater initial cost, and more maintenance

issues. The "closed loop" rhetoric that some manufacturers play up sounds

convincing to the uninitiated, but provides no benefit over a simpler and more

reliable stepper system. [25]

Servo motors are available in larger sizes than stepper motors, and

powerful servos are generally used on heavy machines with gantry carriages in the](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-67-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

58

500 to 1,000 lb range. They offer no advantage whatsoever on lighter machines,

such as Torch mate and its competitors.

Small intelligent motors with 50 oz. in. peak torque and 28 oz. in.

continuous torque are used on one new competitor's cnc machine, although this is

disguised by the citing of output torque at the gearbox. Although these small

motors are expensive, larger intelligent motors would be far more costly. The only

way these relatively low power motors can drive a gantry on a cnc machine is to

run them at a very high rpm with a large gear reduction. This is kind of like

driving your stick shift car around in low gear. This high rpm greatly increases

motor wear, and introduces planetary gearbox backlash into the equation. When a

gearbox first turns in one direction, and then the other, as in cutting a circle, the

backlash in the gear train must be taken up before the direction changes. Unless

super-expensive low-backlash planetary gear boxes are used, as on the large

$100,000 plus machines, circles don't end up in the same place they started, etc.

[25]

Servos are extremely popular with robot, RC plane, and RC boat builders.

Most servo motors can rotate about 90 to 180 degrees. Some rotate through a full

360 degrees or more. However, servos are unable to continually rotate, meaning

they can't be used for driving wheels (unless modified), but their precision

positioning makes them ideal for robot arms and legs, rack and pinion steering, and

sensor scanners to name a few. Since servos are fully self contained, the velocity

and angle control loops are very easy to implement, while prices remain very

affordable. To use a servo, simply connect the black wire to ground, the red to a

4.8-6V source, and the yellow/white wire to a signal generator (such as from your

microcontroller). Vary the square wave pulse width from 1-2ms and your servo is

now position/velocity controlled](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-68-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

59

3.4.2 Servo Voltage (Red and Black/Brown wires)

Servos can operate under a range of voltages. Typical operation is from 4.8V to

6V. There are a few micro sized servos that can operate at less, and now a few

Hitec servos that operate at much more. The reason for this standard range is

because most microcontrollers and RC receivers operate near this voltage. So what

voltage should you operate at? Well, unless you have a battery

voltage/current/power limitation, you should operate at 6V. This is simply because

DC motors have higher torque at higher voltages

3.4.3 Signal Wire (Yellow/Orange/White wire)

While the black and red wires provide power to the motor, the signal wire

is what you use to command the servo. The general concept is to simply send an

ordinary logic square wave to your servo at a specific wave length, and your servo

goes to a particular angle (or velocity if your servo is modified). The wavelength

directly maps to servo angle so how do you apply this square wave to your servo?

If your robot is remote controlled, your RC receiver will apply the proper square

wave for you. If however your robot is running from a microcontroller, you must:

bring high a digital port wait between 1-2ms bring low the same digital port

cycle a few dozen times per second

Note, if you are running multiple servos simultaneously, you can just put a

few of these program blocks in sequential order. You can run as many servos as

you have of digital ports. [25]

So how many milliseconds do you keep the port high? It all depends on the

servo. You may have to tweak for each individual servo some several

microseconds‟ difference.

The standard time vs. angle is represented in this chart:](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-69-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

60

Figure 3.6 Timing diagram of servo motor

3.4.4 Servo Current

Servo current operates the same as in a DC motor, except that you now also

have a hard to predict feedback control system to contend with. If your DC motor

is not at the specified angle, it will suddenly draw huge amounts of current to reach

that angle. But there are other peculiarities as well. If you run an experiment with a

servo at a fixed angle and hang precision weights from the servo horn, the

measured current will not be what you expect. One would think that the current

would increase at some fixed rate as the weights increased linearly. Instead you

will get unpredictable curves and multiple rates. In conclusion, servo current draw

is very unpredictable. [25]

3.4.4.1 Stall Torque, Stall Current, Current Drain

Since servos contain DC motors, please read my DC motor tutorial to learn about

servo stall characteristics.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-70-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

62

Unfortunately, due to wear, metal gears will eventually develop slight play in the

gear-train. Accuracy will slowly be lost. [25]

3.4.6 Velocity

The servo turn rate, or transit time, is used for determining servo rotational

velocity. This is the amount of time it takes for the servo to move a set amount,

usually 60 degrees. For example, suppose you have a servo with a transit time of

0.17sec/60 degrees at no load. This means it would take nearly half a second to

rotate an entire 180 degrees. More if the servo were under a load. This information

is very important if high servo response speed is a requirement of your robot

application. It is also useful for determining the maximum forward velocity of your

robot if your servo is modified for full rotation. Remember, the worst case turning

time is when the servo is at the minimum rotation angle and is then commanded to

go to maximum rotation angle, all while under load. This can take several seconds

on a very high torque servo.

3.4.7 Efficiency and Noise

Due to noise and control circuitry requirements, servos are less efficient

than DC motors uncontrolled. To begin with, the control circuitry typically drains

5-8mA just on idle. Secondly, noise can more than triple current draw during a

holding position (not moving), and almost double current during rotation. Noise is

often a major source of servo inefficiency and therefore should be avoided. Ever

notice your servo jitter or vibrate? This is because your servo is rapidly jumping

between two different angles due to interference. What causes this interference?

Well the signal wire is no different than long antennae, capable of accepting

unwanted foreign signals and sending them straight to your servo as a command. A

common interference source is usually from other nearby servos and/or servo

wiring. How to prevent this problem? Keep your signal wire short, meaning do not

add say 3+ feet of extension cables to your servo. If you have many servo wires

going through one area, and it isn‟t feasible to keep them apart, then twist them

together. Supposedly this reduces cross interference and I've heard it works,](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-72-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

64

3.4.9 Hitec vs Futaba

There are actually four major servo manufacturers - Hitec, Futaba,

Airtronics, and JR Radios. The last two are uncommon today, so I wont talk about

them. Hitec and Futaba servos work the same, but there are several interfacing

differences which you should be aware of.

Figure 3.8 (a) Wire Configuration (b) Wire Configuration

The first is wire color, as Hitec uses a yellow signal wire while Futaba uses

a white one. The wiring order is the same, just different colors.

The second is connector compatibility. Futaba (J type) has a special flange thingy

while Hitec (S type, for universal) does not. Futaba has the extra flange to help the

user plug in the servo correctly, although there are only two ways to do it and

connecting a servo in the wrong way will not actually damage anything. If you

want to connect a Futaba servo to a Hitec device, just clip the flange off and use

sandpaper to file it down until it fits. If you ever need to connect a Hitec connector

to something Futaba, just use sandpaper to decrease the connector width until it

fits. [25]

The third is price. All things kept the same; Hitec servos are cheaper than

Futaba servos. But don't let this be your only determining factor in your decision,

as Futaba has some servo sizes that Hitec does not.

The last major difference is in the spline. The spline is the output shaft of

the servo. This is where you would attach your servo horn or servo arm. Standard

Hitec splines have 24 teeth while standard Futaba splines have 25 teeth. What

makes this important is that servo horns built for one will not work with the other.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-74-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

65

3.5 ARM MANIPULATOR

Plant of the System is the manipulator joints called Shoulder joint and

Elbow joint. Main feature of these joints are Link joints, material selection,

Specification of different joints parameters and sketches of views of different parts

discussed in below.

3.5.1 Hardware Design

This section reports the mechanical design of actuators and links of the

robotic arm. [23]

3.5.2 Planning about Hardware of the System

To considered the Area of Work space.

Length and Span of Shoulder & Elbow w.r.t. Work Space

Maximum Angular Displacement of both joints.

Other Geometrical Parameters.

Mass of shoulder & elbow.

Mathematical modeling & Trajectory Planning.

Selection of Light, Stiff & Easy to Fabricate Material.

Selection of Servomotors of proper power & load bearing capability

3.5.3 Link Design

We use finite-element method to optimize the design of two links of robotic

arm. The objective of optimization was to converge on link design that would

cause the robotic arm to exhibit high structural vibration frequencies over entire

workspace of the robotic arm. The continuously varying nature of structure results

in change in the stiffness and mass characteristic relative to a fixed reference,

necessitating a range of resonant frequencies is predicted. Hence we optimized the

design and evaluated structural vibration modes over a large chunk of the

workspace.](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-75-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

67

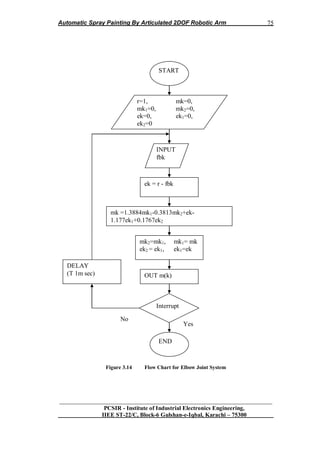

3.6 Designing of Digital Controller

Digital controller used for this task is ON-OFF type as mention in

Article 1.2.3. [2]

There are several steps in Digital control design which are:

Step1: Output parameter D(z) for step input R(z).

)(

)(1

)(

)( zR

zG

zG

zC

[2] (3.1)

Therefore, for Shoulder

)4493.4492.12.1)(1(

2726.02722.02.0(

)( 2

2

2

zzz

zzz

zC (3.2)

Similarly, for Elbow

)279.2827.1076.1)(1(

)1023.01057.0076.0(.

)( 2

2

2

zzz

zzz

zC (3.3)

Step 2: Digital Controller Gc(z)

))(/)(1(

)(/)(

)(

1

)(

zRzC

zRzC

zG

zGc

[2] (3.4)

Therefore, for shoulder

2726.02722.02.0

1767.177.1

)( 2

2

1

zz

zz

zGc (3.5)

Similarly for Elbow

3813.3884.1

1767.0177.1

)( 2

2

2

zz

zz

zGc (3.6)

Step3: Manu plated Output Variable

M(z) = Gc(z) E(z) (3.7)

Difference equation of controller for shoulder

m1(k) = 1.131m(k-1)-0.2m(k-2) +1.25e(k)-1.5e(k-1)+0.221e(k-2) (3.8)

Difference equation of controller for Elbow

m2(k) = 1.3884m(k-1)-0.3818m(k-2)+e(k)-1.177e(k-1)+0.1767e(k-2) (3.9)](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-77-320.jpg)

![Automatic Spray Painting By Articulated 2DOF Robotic Arm

__________________________________________________________________

PCSIR - Institute of Industrial Electronics Engineering,

IIEE ST-22/C, Block-6 Gulshan-e-Iqbal, Karachi – 75300

II

DelayMS 4

Next j

SerIn PORTB.7,16468,[info] „Receive Data serially and „save in

“info” variable

‘**********************************************************************

‘* Decide on the base of received data which sub routine to execute *

‘**********************************************************************

If info="A" Then

GoSub sub_A

EndIf

If info="B" Then

GoSub sub_B

EndIf

If info="C" Then

GoSub sub_C

EndIf

If info="D" Then

GoSub sub_D

EndIf

If info="E" Then

GoSub sub_E

EndIf

If info="F" Then

GoSub sub_F

EndIf

If info="G" Then

GoSub sub_G

EndIf

If info="H" Then

GoSub sub_H

EndIf

If info="I" Then

GoSub sub_I

EndIf

If info="J" Then

GoSub sub_J](https://image.slidesharecdn.com/7573919b-24e9-426a-bbb5-45e558786365-161205174731/85/Project_Report_433-110-320.jpg)