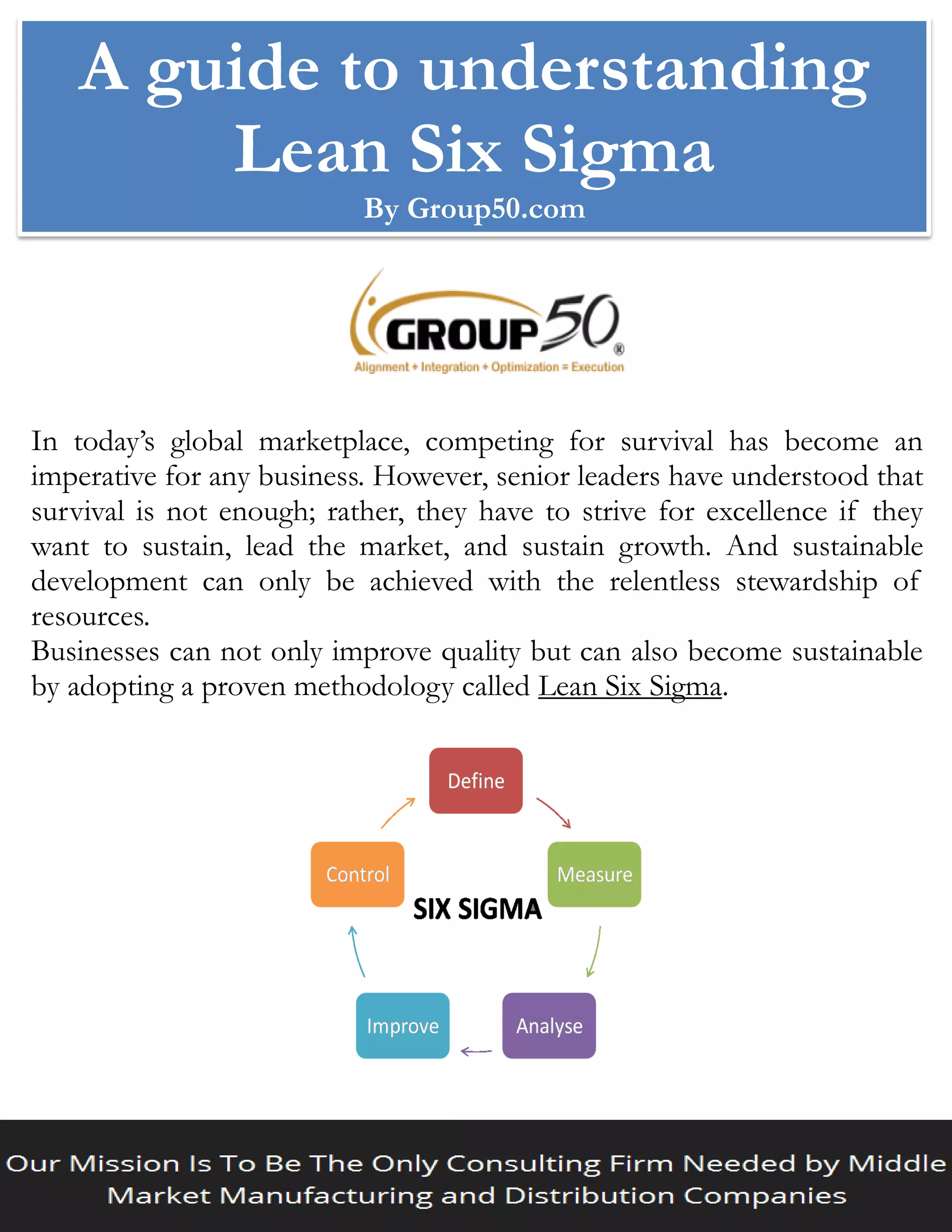

The document discusses Lean Six Sigma as a crucial methodology for businesses to improve quality, reduce waste, and achieve sustainable performance in a competitive marketplace. It outlines the framework of Lean Six Sigma, which combines lean manufacturing and six sigma principles, emphasizing five steps: define, measure, analyze, improve, and control (DMAIC). The approach offers numerous benefits, including enhanced customer value, increased productivity, improved adaptability, and innovation, but requires a strategic commitment and cultural integration within the organization.