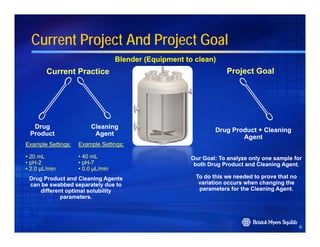

This document discusses using design of experiments to evaluate combining the analysis of cleaning agents and drug products using total organic carbon analysis. A factorial design of experiments was conducted varying pH, volume, and oxidizer flow rate during analysis of cleaning agents. The results showed little to no variation between factors, indicating parameters can be changed without affecting results. Additionally, even the worst variation was small compared to the permitted residue limit. Therefore, cleaning agents and drug products can be analyzed together in one sample to streamline the process without increasing risk.