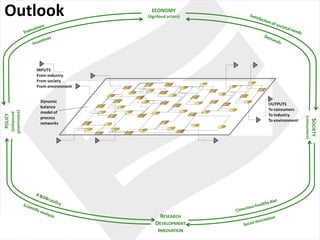

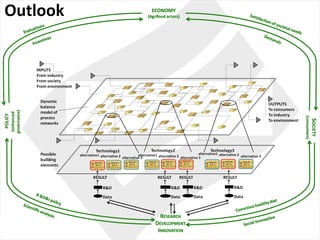

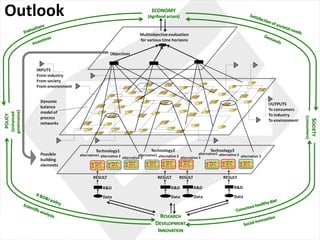

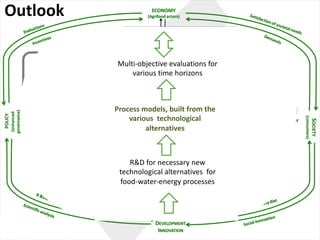

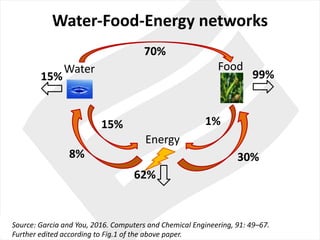

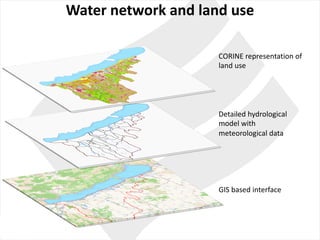

The document discusses the integration of water, food, energy, and ecosystem networks through process model-based decision support to harmonize local interests with global sustainability. It emphasizes the use of quantitative decision support methods in process systems engineering to address challenges posed by climate change and infrastructure complexity, highlighting collaborative efforts with various institutions. The approach aims to utilize modeling, simulation, and big data to enhance decision-making and promote sustainable practices across different sectors.

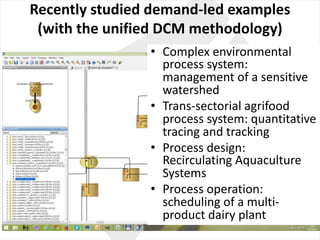

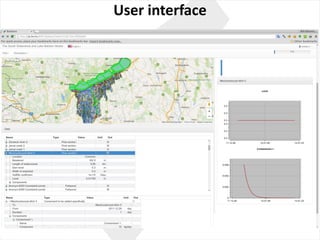

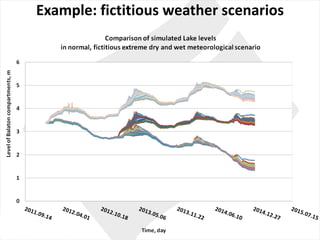

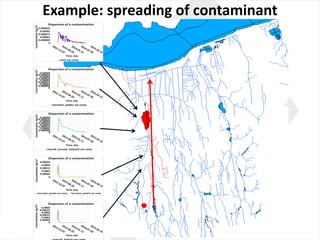

![Recently studied demand-led examples

• Complex environmental

process system:

management of a sensitive

watershed [1, 2]

• Trans-sectorial agrifood

process system: quantitative

tracing and tracking

• Process design:

Recirculating Aquaculture

Systems

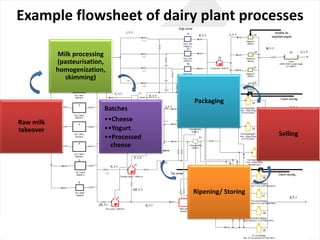

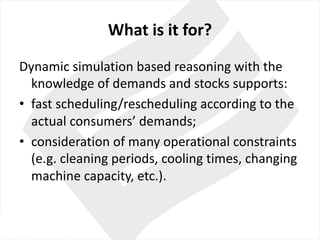

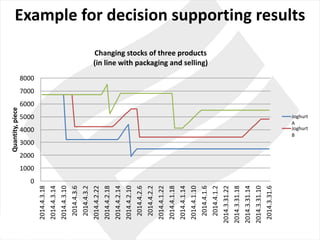

• Process operation:

scheduling of a multi-

product dairy plant](https://image.slidesharecdn.com/vmv5monikavarga-161215152217/85/Process-model-based-decision-support-for-multi-stakeholder-water-food-energy-ecosystem-network-10-320.jpg)

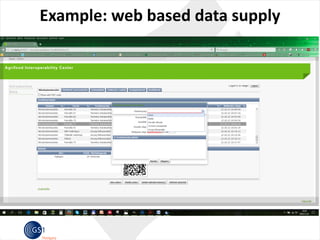

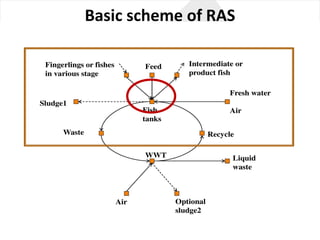

![Recently studied demand-led examples

• Complex environmental

process system: management

of a sensitive watershed

• Trans-sectorial agrifood

process system: quantitative

tracing and tracking [2, 3, 4,

10]

• Process design: Recirculating

Aquaculture Systems

• Process operation: scheduling

of a multi-product dairy plant](https://image.slidesharecdn.com/vmv5monikavarga-161215152217/85/Process-model-based-decision-support-for-multi-stakeholder-water-food-energy-ecosystem-network-17-320.jpg)

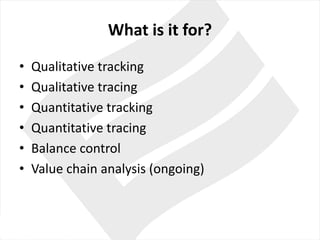

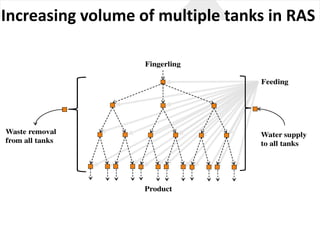

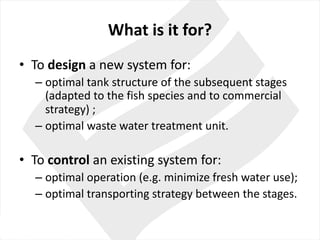

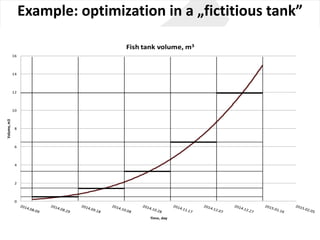

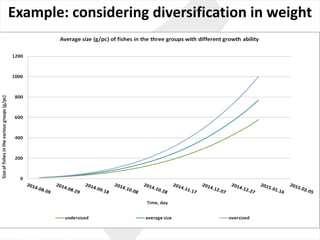

![Recently studied demand-led examples

• Complex environmental

process system:

management of a sensitive

watershed

• Trans-sectorial agrifood

process system: quantitative

tracing and tracking

• Process design:

Recirculating Aquaculture

Systems [5, 6, 8]

• Process operation:

scheduling of a multi-

product dairy plant](https://image.slidesharecdn.com/vmv5monikavarga-161215152217/85/Process-model-based-decision-support-for-multi-stakeholder-water-food-energy-ecosystem-network-24-320.jpg)

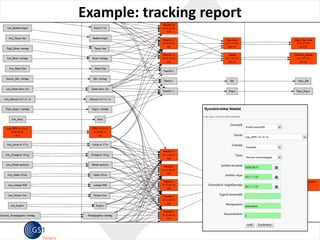

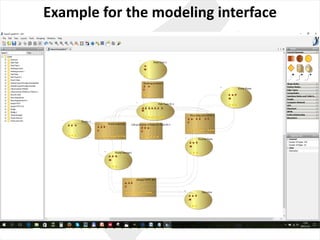

![Recently studied demand-led examples

• Complex environmental

process system:

management of a sensitive

watershed

• Trans-sectorial agrifood

process system: quantitative

tracing and tracking

• Process design:

Recirculating Aquaculture

Systems

• Process operation:

scheduling of a multi-

product dairy plant [7, 9]](https://image.slidesharecdn.com/vmv5monikavarga-161215152217/85/Process-model-based-decision-support-for-multi-stakeholder-water-food-energy-ecosystem-network-33-320.jpg)