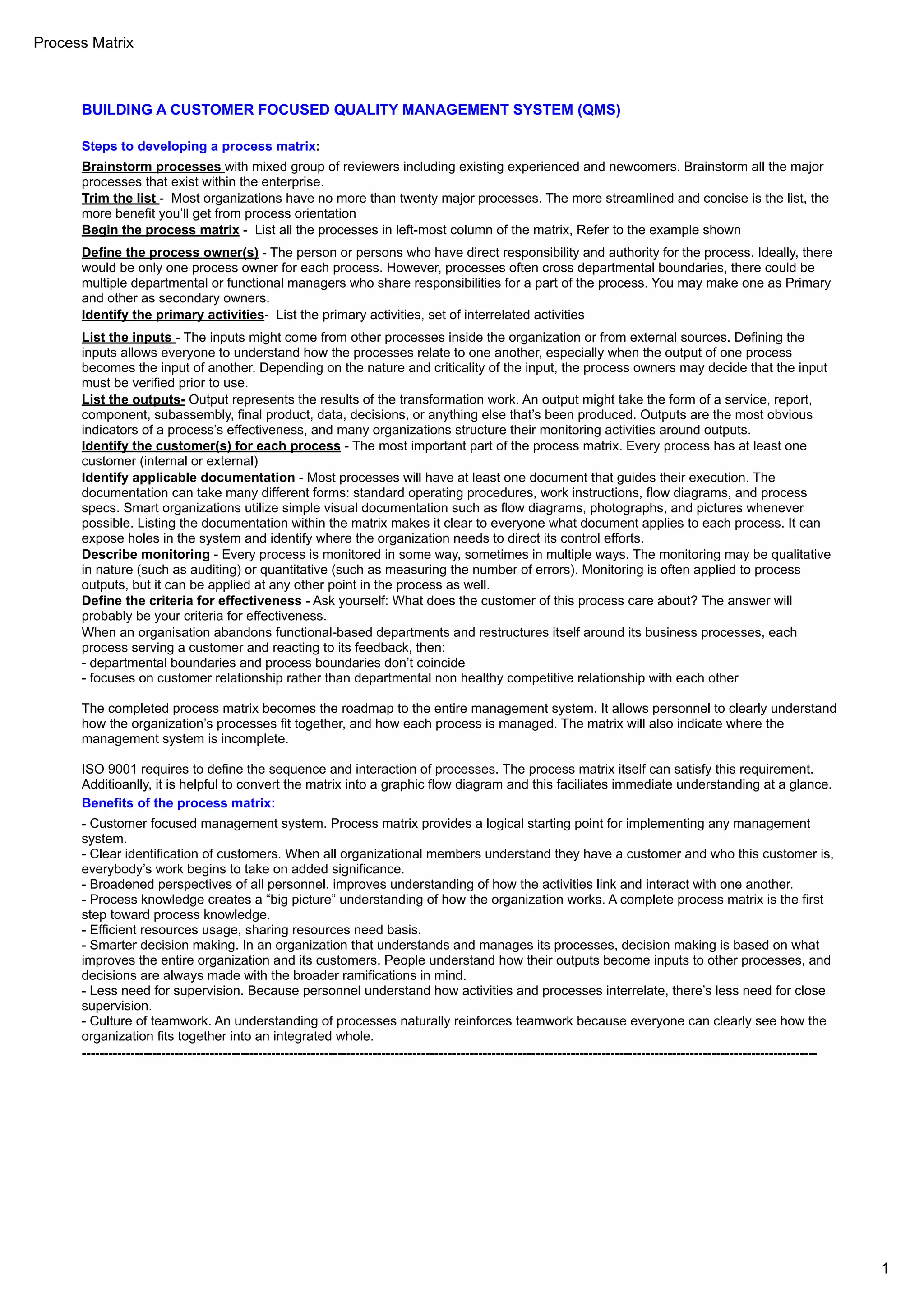

The document describes steps for developing a process matrix to build a customer-focused quality management system. It involves brainstorming all major processes, trimming the list to around 20 processes, and creating a matrix template. For each process, the matrix identifies the owner, activities, inputs, outputs, customers, documentation, monitoring, and effectiveness criteria. Completing the process matrix provides a roadmap for understanding how processes fit together and are managed to create a customer-focused system with benefits like improved understanding, decision-making, and teamwork. An example process matrix is also provided.

![Process Matrix

3

[NOTE: there may

be multiple

realization

processes,

depending on the

diversity of activities

involved]

Production

Mgr

Producing

product/service

Raw materials Certificates of

Analysis

Product

inspections

Net income

Verifying product Supplies Business review

meetings

Calibrating all

measuring

equipment

electricity,

downtime

Weekly

production

roundup

Providing

feedback

Human resources

Tools &

equipment

Product

specifications

Engineering

drawings

7. Control of

nonconforming

product

Production

Mgr

Identifying

nonconforming

products

Inspection criteria Dispositions Internal audit Complete

adherence to

procedure

Determining

Dispositions

Procedure for

control of

nonconforming

products

Corrective actions Number of Major/

minor NCs

Taking corrective

actions

Cost of Quality

8. Outbound

process

Logistics

Mgr

Packaging Final product Delivered product Internal audit % on-time

delivery

Labeling Delivery dates Damage-free

handling &

storage

Business review

meetings

Net income

Warehousing Packaging

materials

% Recalled /

Returned

Material handling Labels

Scheduling

pickups

Trucking services

Shipping

9. Customer

satisfaction

Director of

Sales

Develop tools for

gauging

perceptions

Field report forms Customer

feedback

Internal audit Revenue growth

Capturing

feedback

Field report

schedules

Trends Business review

meetings

Net income

Analyzing results Prioritized

opportunities

Taking action

10. Business

review

General

Manager

Reviewing

implementation of

business plan

Business plan Preventive

actions

Internal audit Achievement of

business plan

Monitoring

progress on key

measures

Performance data Business plan

revisions

Improvement of

key measures

Analyzing all

other required

inputs

Key measures Strategic

decisions

Net income

Capacity planning

Analysis of

skillset](https://image.slidesharecdn.com/processmatrix-230702061559-973e1b3a/85/Process-Matrix-pdf-3-320.jpg)