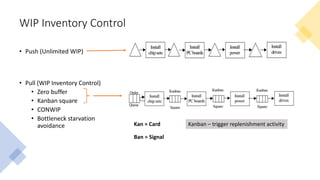

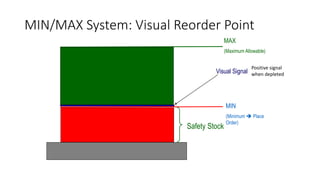

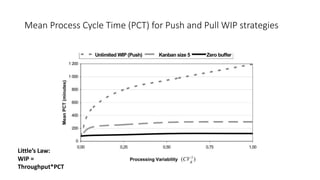

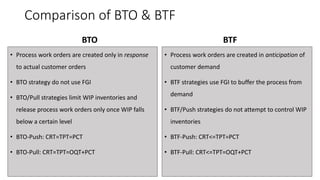

This document summarizes a presentation about process control at Compaq. It discusses Compaq's build-to-order decision model and key performance measures like capacity, responsiveness, and inventory. It also covers process control strategies like push vs pull and build-to-order vs build-to-forecast. Specifics around Compaq's computer assembly line are provided, including station processing times and calculations of expected cycle times under different strategies using queueing theory models. The presentation concludes by discussing how optimal kanban sizes can be determined to minimize cycle times.

![From Queueing theory,

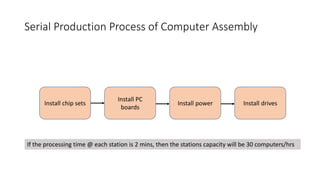

Utilization rate = (23/30) = 0.77 ~ 77%, τi = Mean Service Time = 2 minutes

Wi = 2 x {0.77/(1-0.77)} = 26.5 minutes

E[CRT] = E[PCT] = ΣWi + τi = 26.5 + (2x4) = 34.5 minutes

E[CRT] is 34.5 minutes under the BTO push strategy.

Where(Wi) – expected time spent at each station](https://image.slidesharecdn.com/processcontrolatcompaq-221213091656-4014ad57/85/Process-control-at-Compaq-pptx-16-320.jpg)

![E[PCT] of the proposed BTO/Pull strategy with Kanban size](https://image.slidesharecdn.com/processcontrolatcompaq-221213091656-4014ad57/85/Process-control-at-Compaq-pptx-18-320.jpg)

![E[OQT] of the proposed BTO/Pull strategy with Kanban size](https://image.slidesharecdn.com/processcontrolatcompaq-221213091656-4014ad57/85/Process-control-at-Compaq-pptx-19-320.jpg)

![E[CRT] of the proposed BTO/Pull strategy with Kanban size](https://image.slidesharecdn.com/processcontrolatcompaq-221213091656-4014ad57/85/Process-control-at-Compaq-pptx-20-320.jpg)