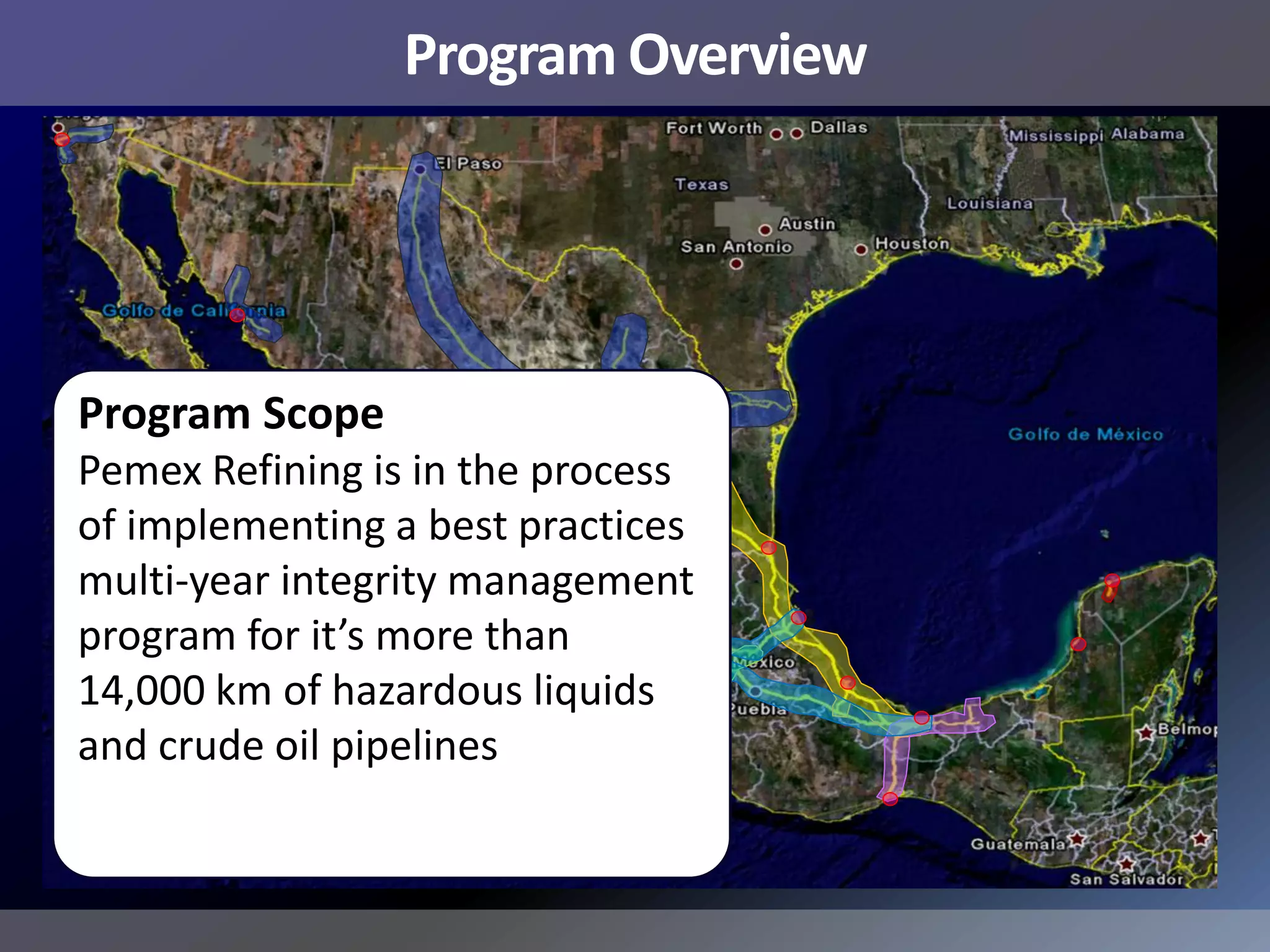

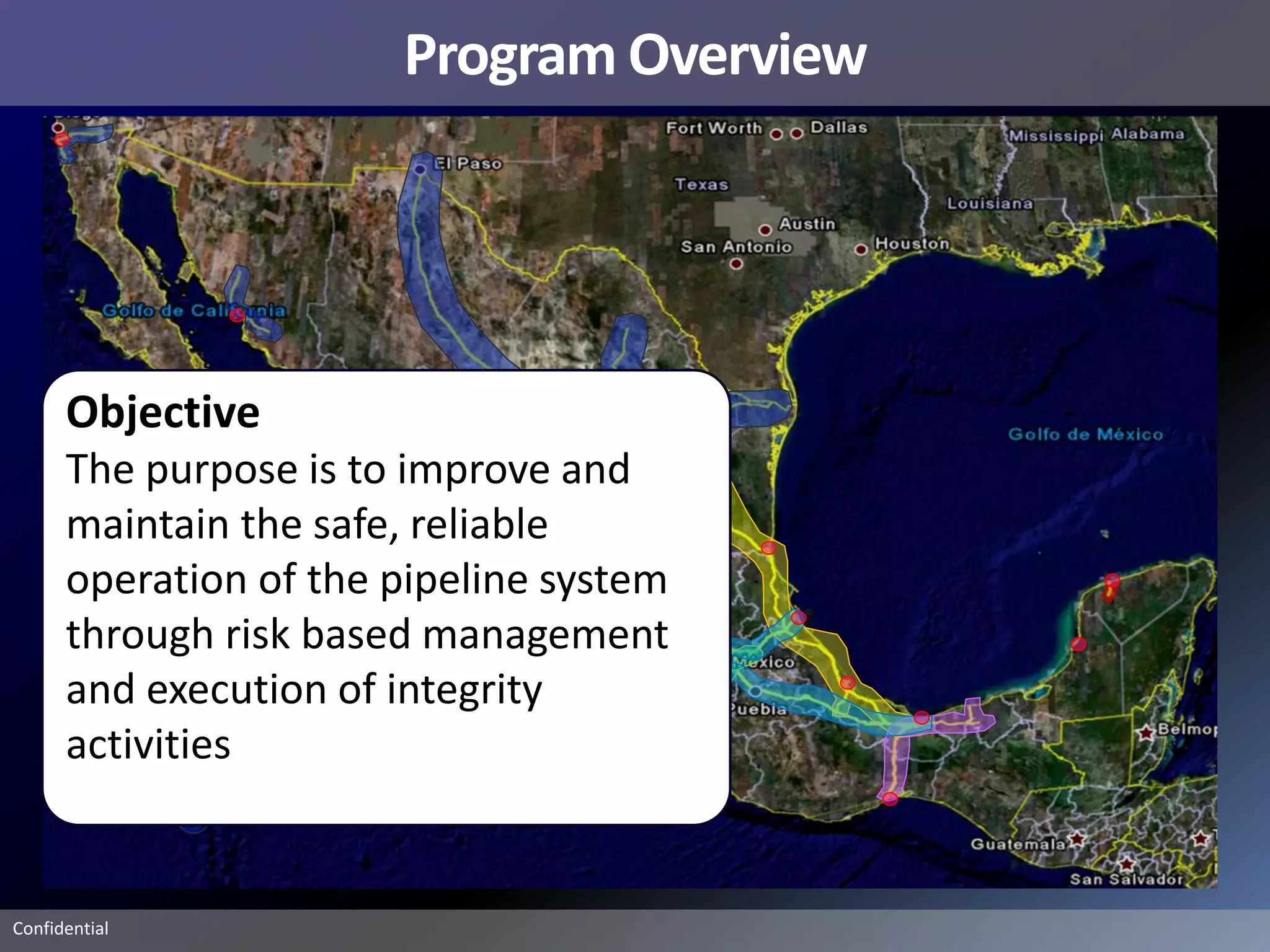

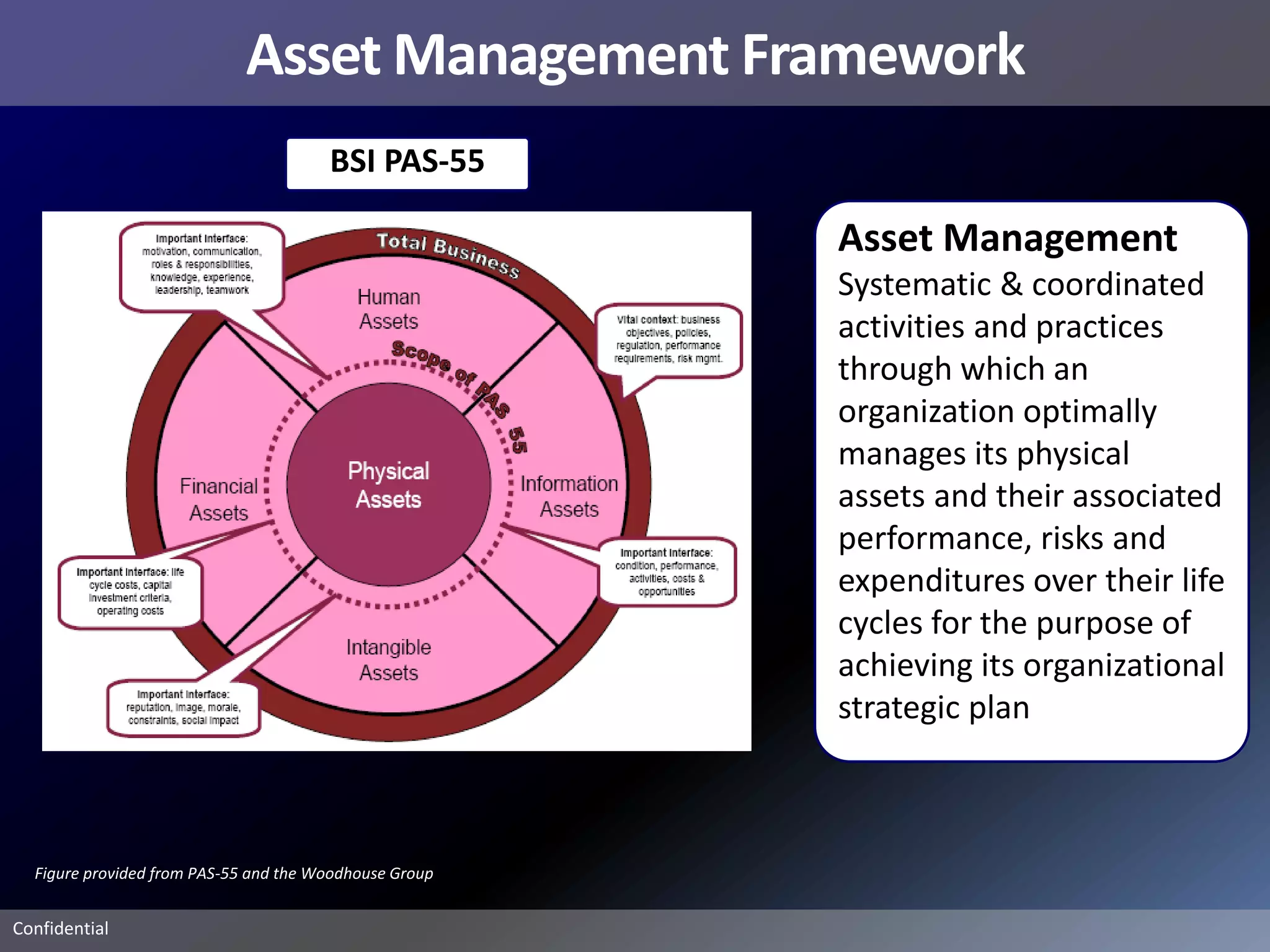

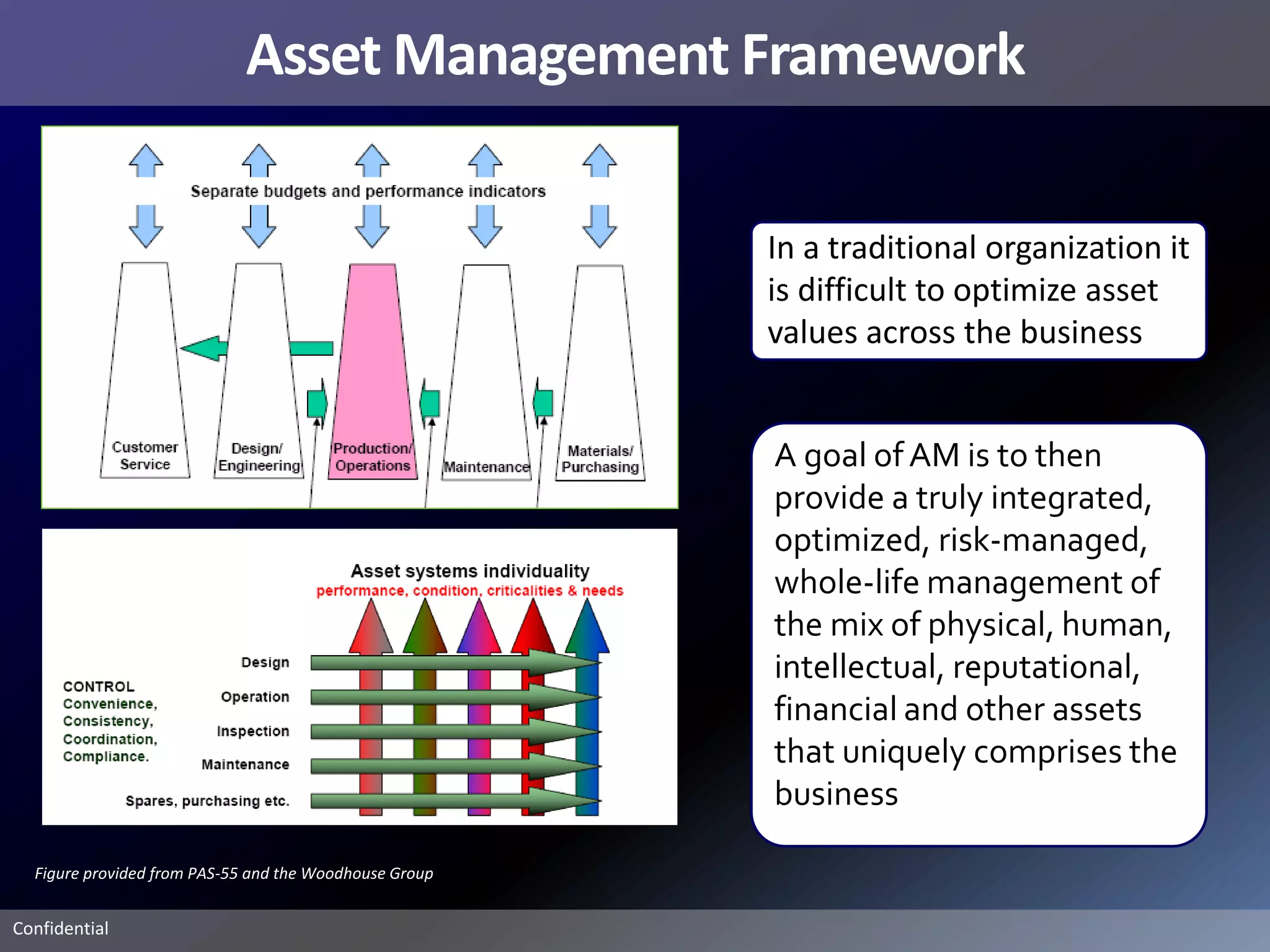

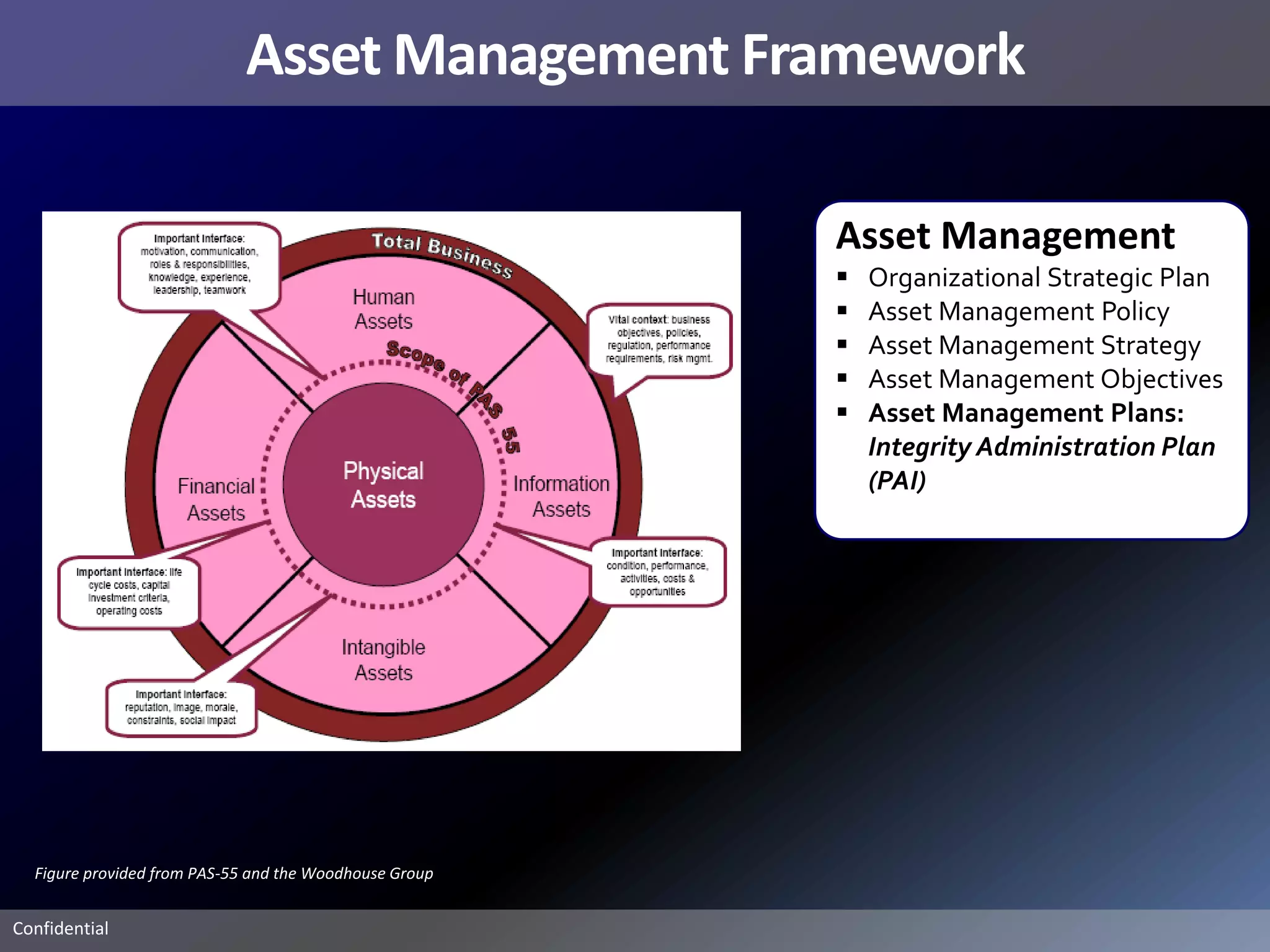

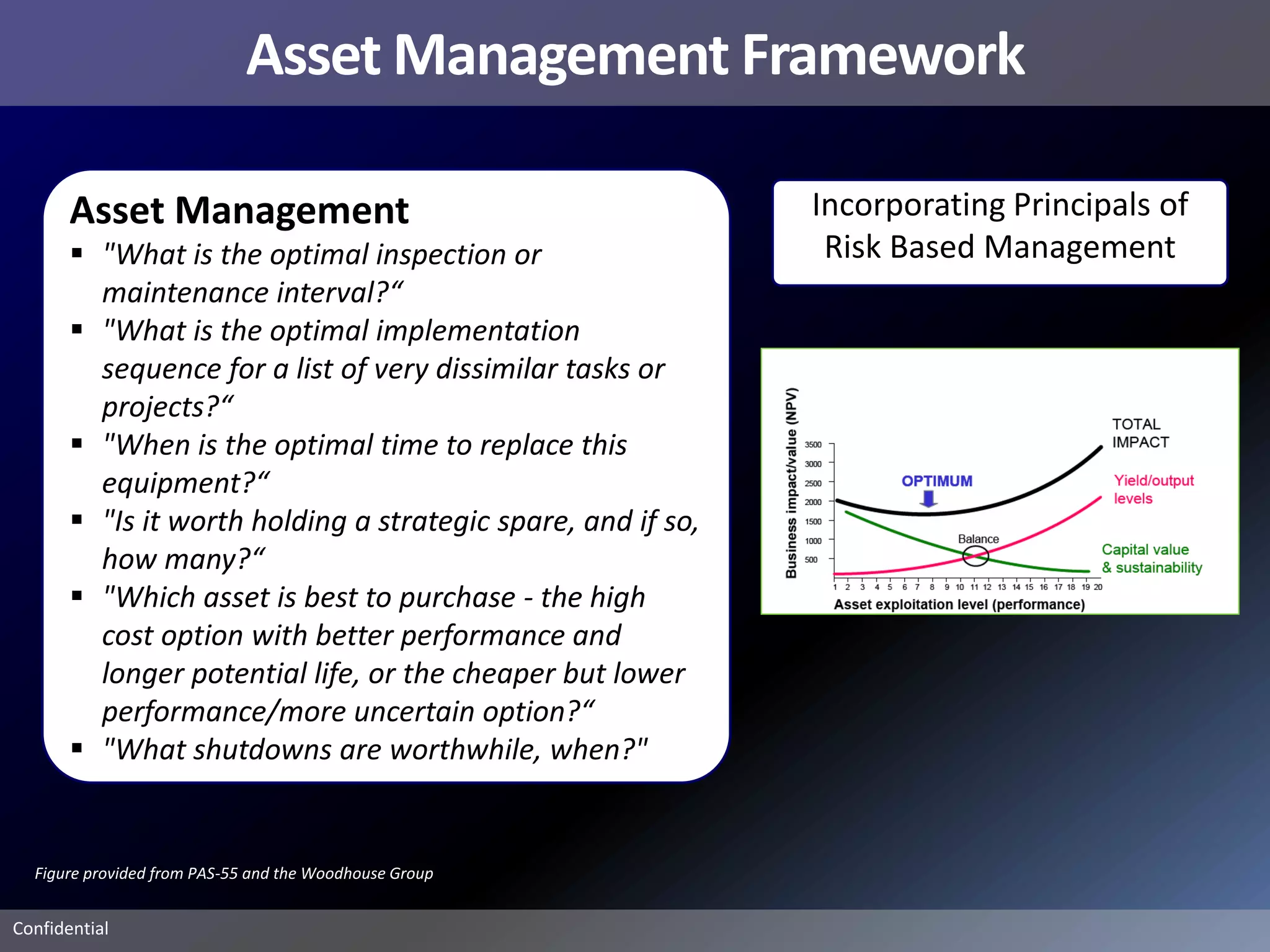

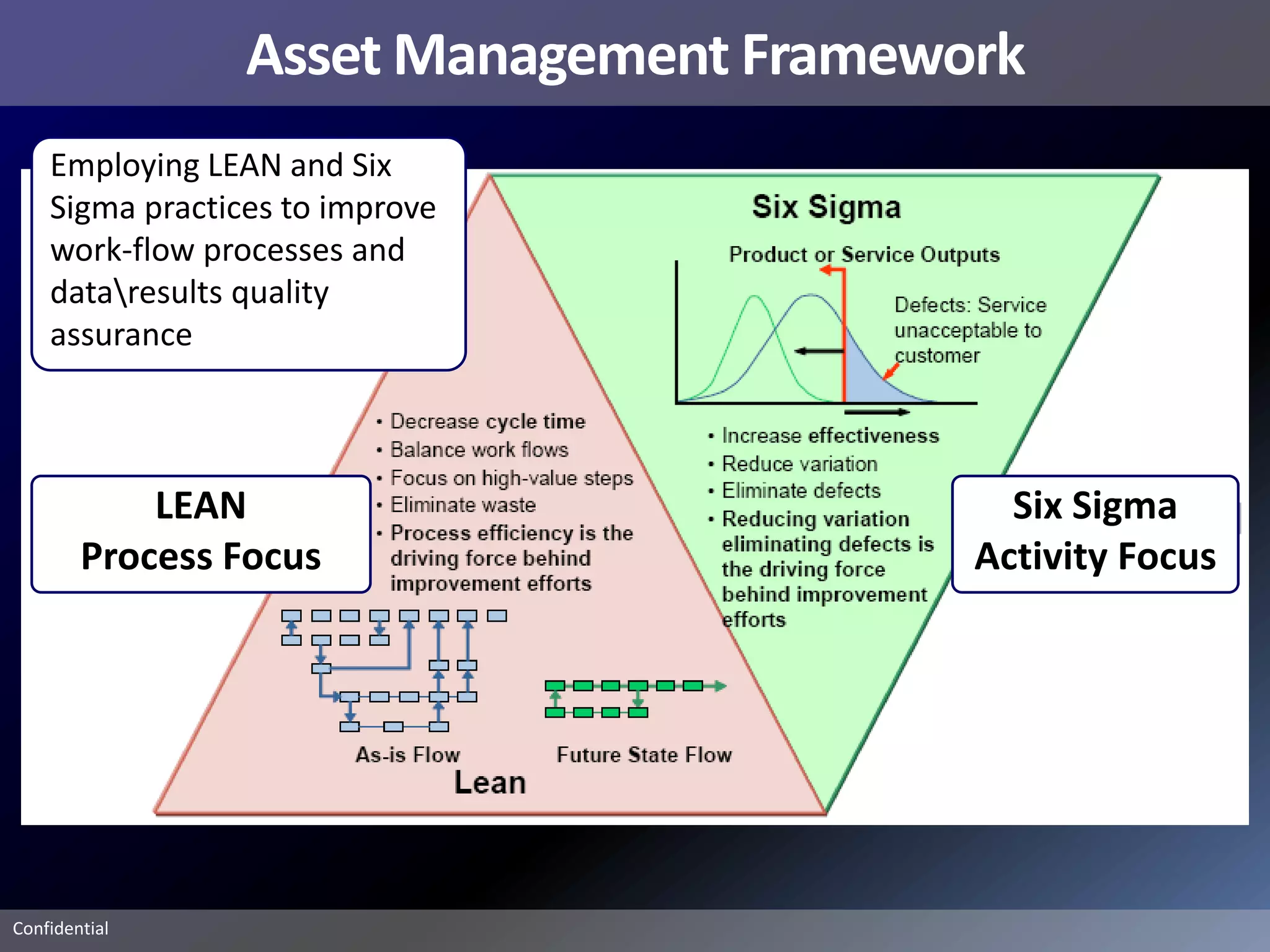

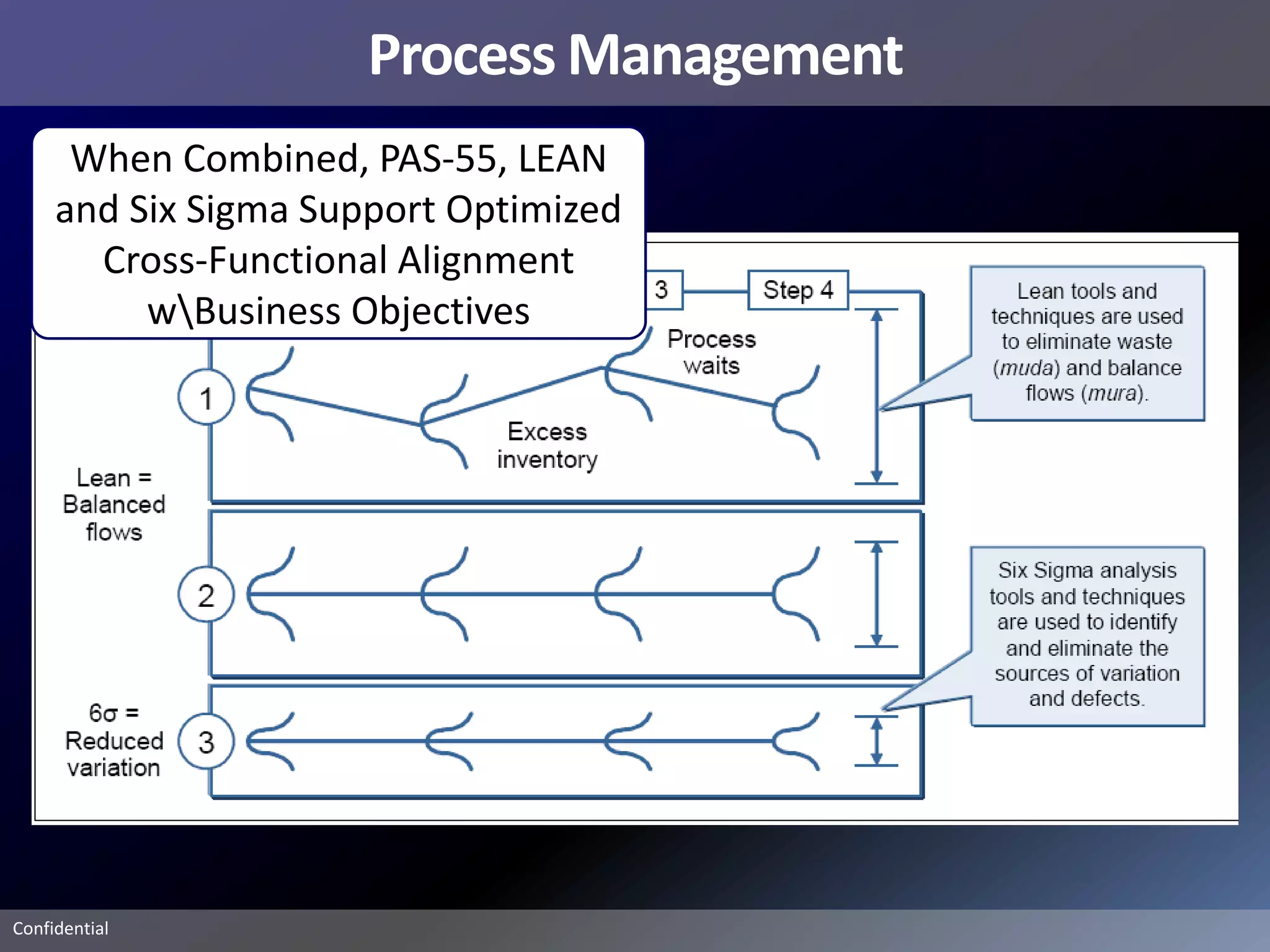

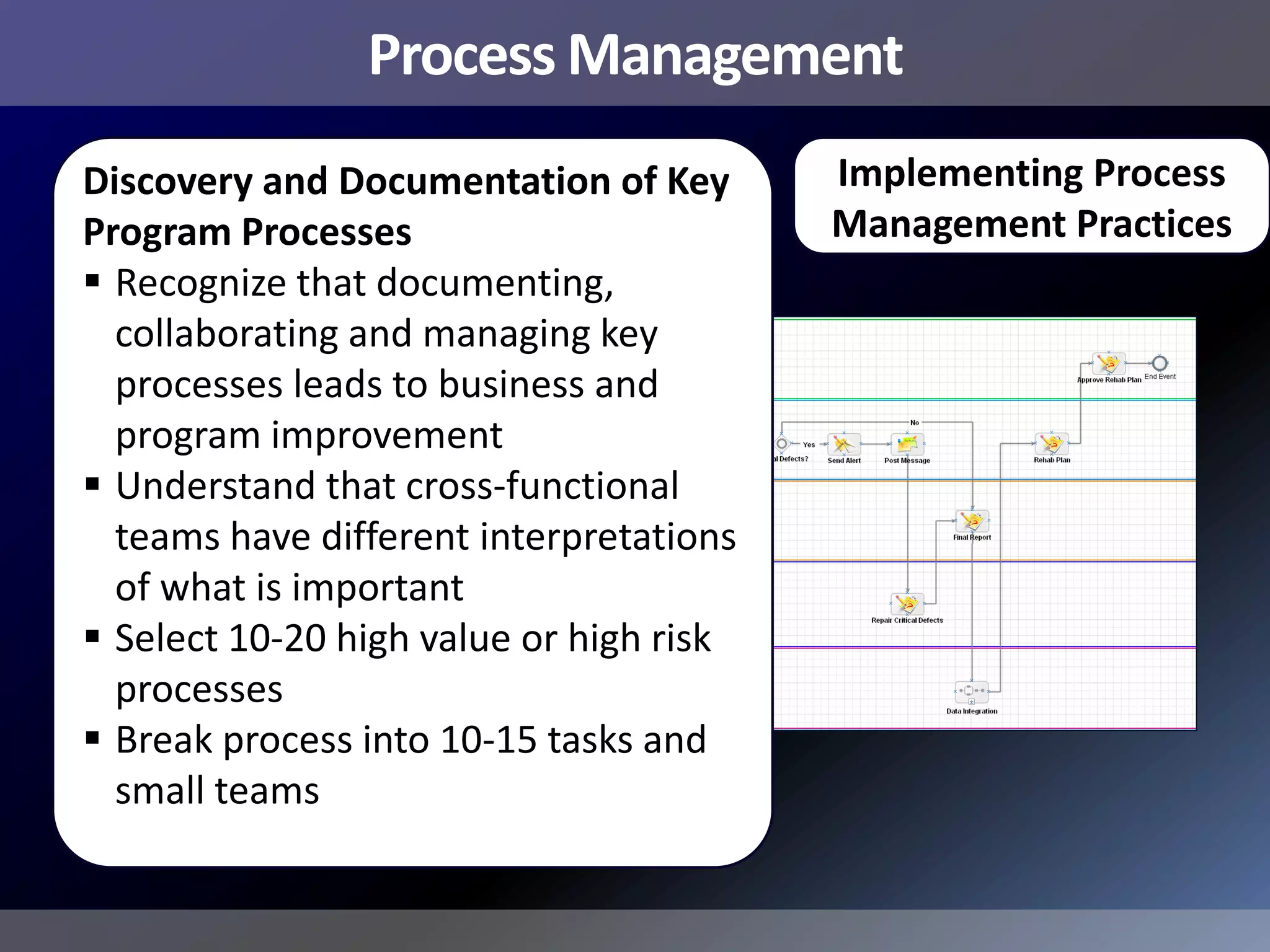

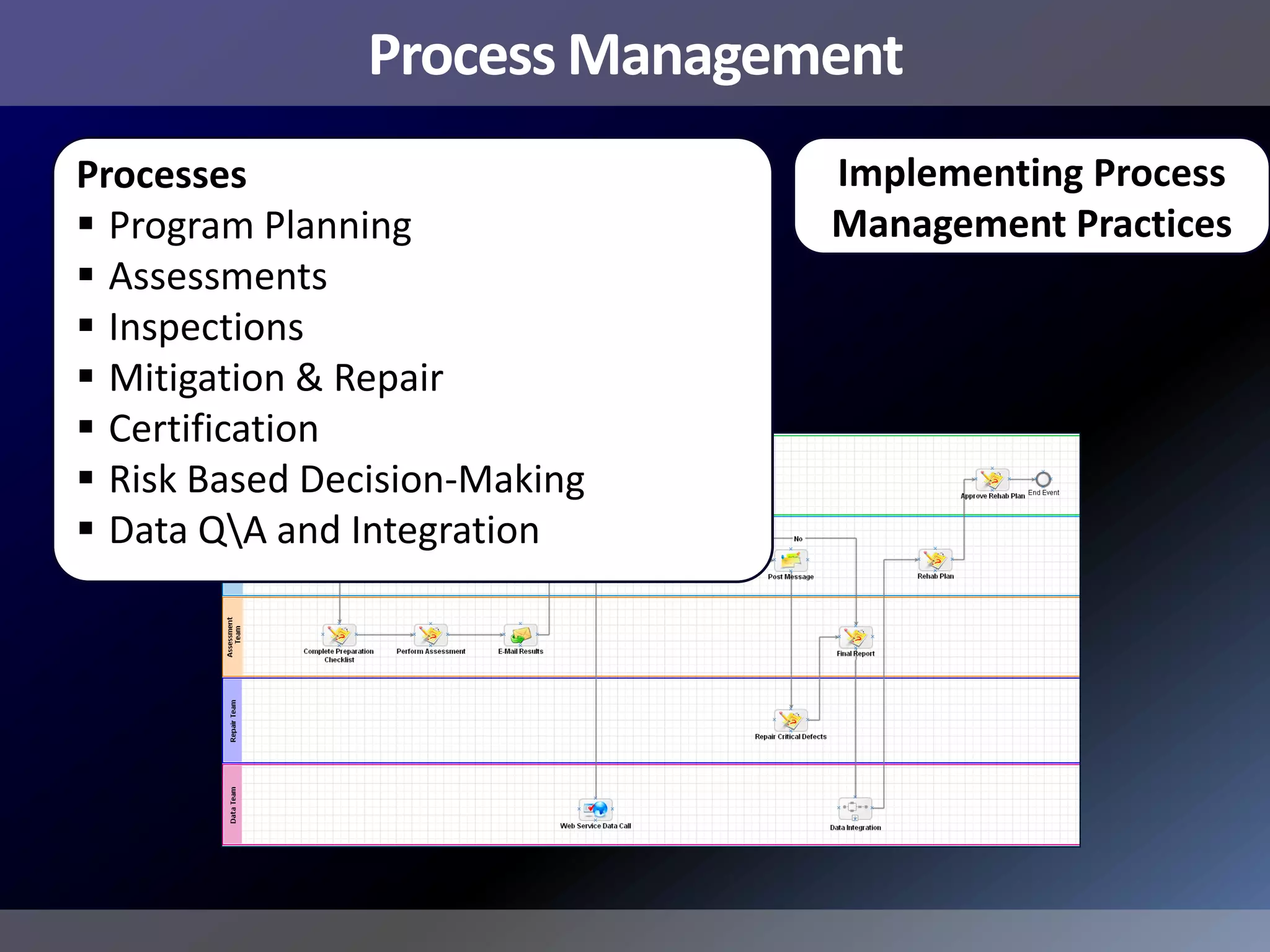

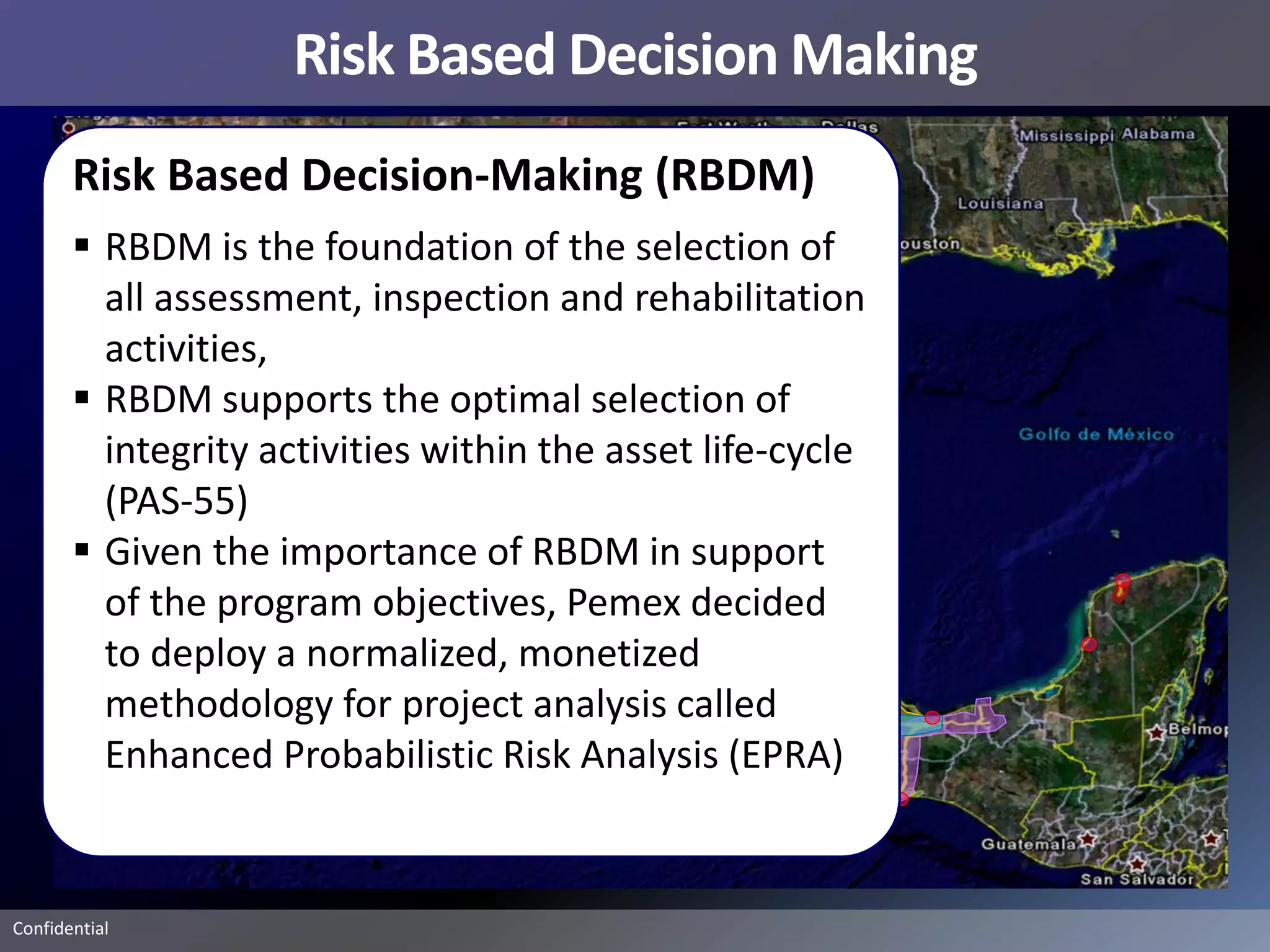

Pemex Refining is implementing a best practices pipeline integrity management program for its 14,000 km pipeline system. It is using an asset management framework based on BSI PAS-55 standards and risk-based decision making. It has selected key processes to document and improve using Lean and Six Sigma. It is supporting the program with a web-based integrity management system to manage the asset lifecycle and risk-based activities.

![Risk Based Decision Making

PFIM LOF Algorithm Structure

Broaden KPI’s to AM Life-

Threat EC IC SCC TPD WOF MFG CON IO

Cycle

EQ

Categories

What is value of asset

given it’s operational risk

Variable Exposure Mitigation Resistance

profile, required

Categories

maintenance investments

Attributes and business value?

Attribute

Score E1 E2 E3 M1 M2 M3 R1 R2 R3

Variable

Weight WE1 WE2 WE3

Exposure = Mitigation = Resistance =

(VariableE1 * WE1) + … 1 – [(1 - VariableM1) * … 1 – [(1 - VariableR1) * …

(VariableEn * WEn) (1 - VariableMn) (1 - VariableRn)

WOF Threat Score = (Exposure) * (1 - Mitigation) * (1 – Resistance)

LOF Score = 1 – [(1-EC) * (1-IC) * (1-SCC) * (1-TPD) * (1-WOF) * (1-MFG) * (1-CON) * (1-IO) * (1-EQ)]

ROF Score = LOF Score * COF Score

Confidential](https://image.slidesharecdn.com/imspemexcasestudy-monterrey2009-120325212513-phpapp02/75/Process-Centric-Integrity-Management-20-2048.jpg)