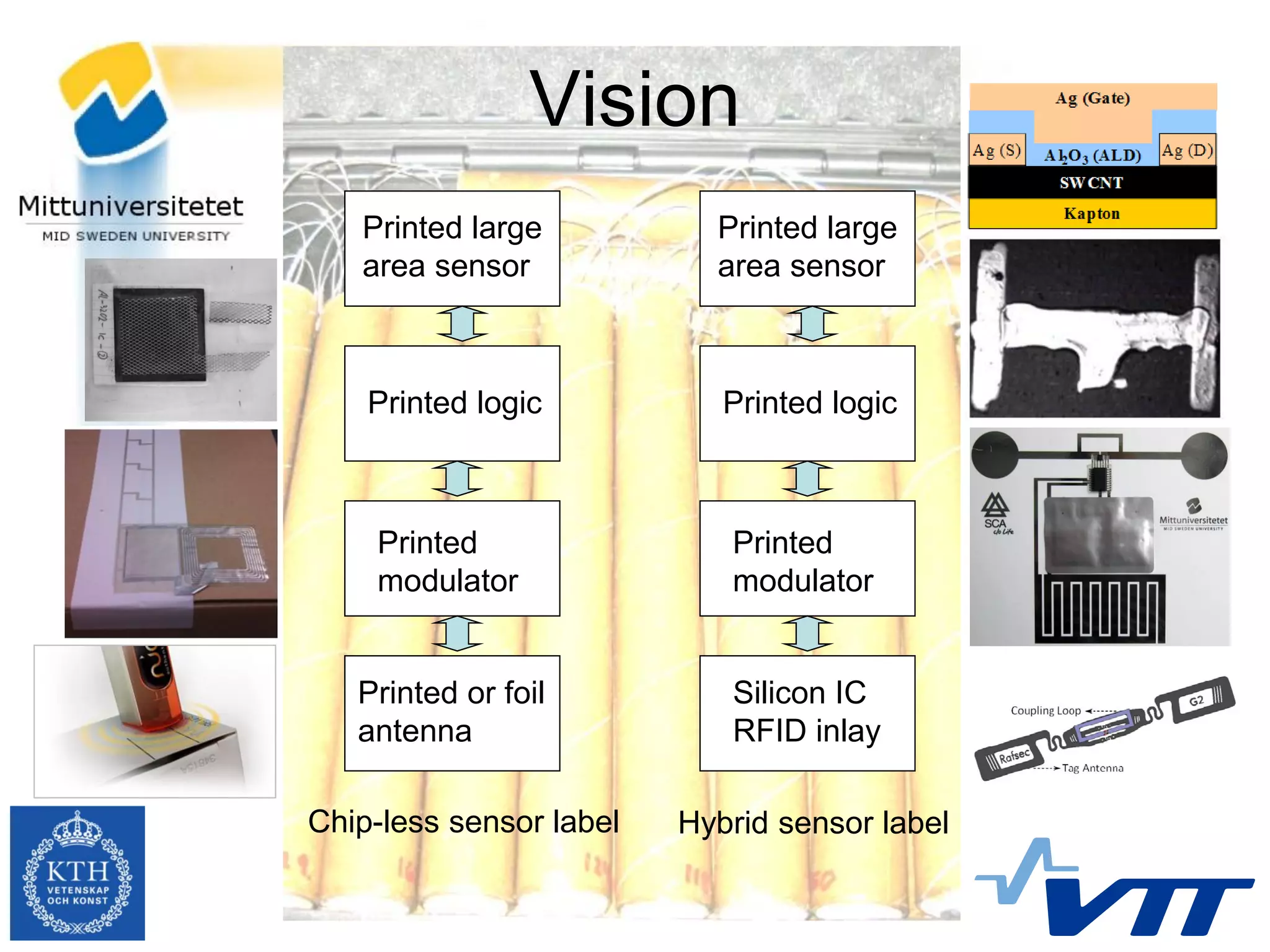

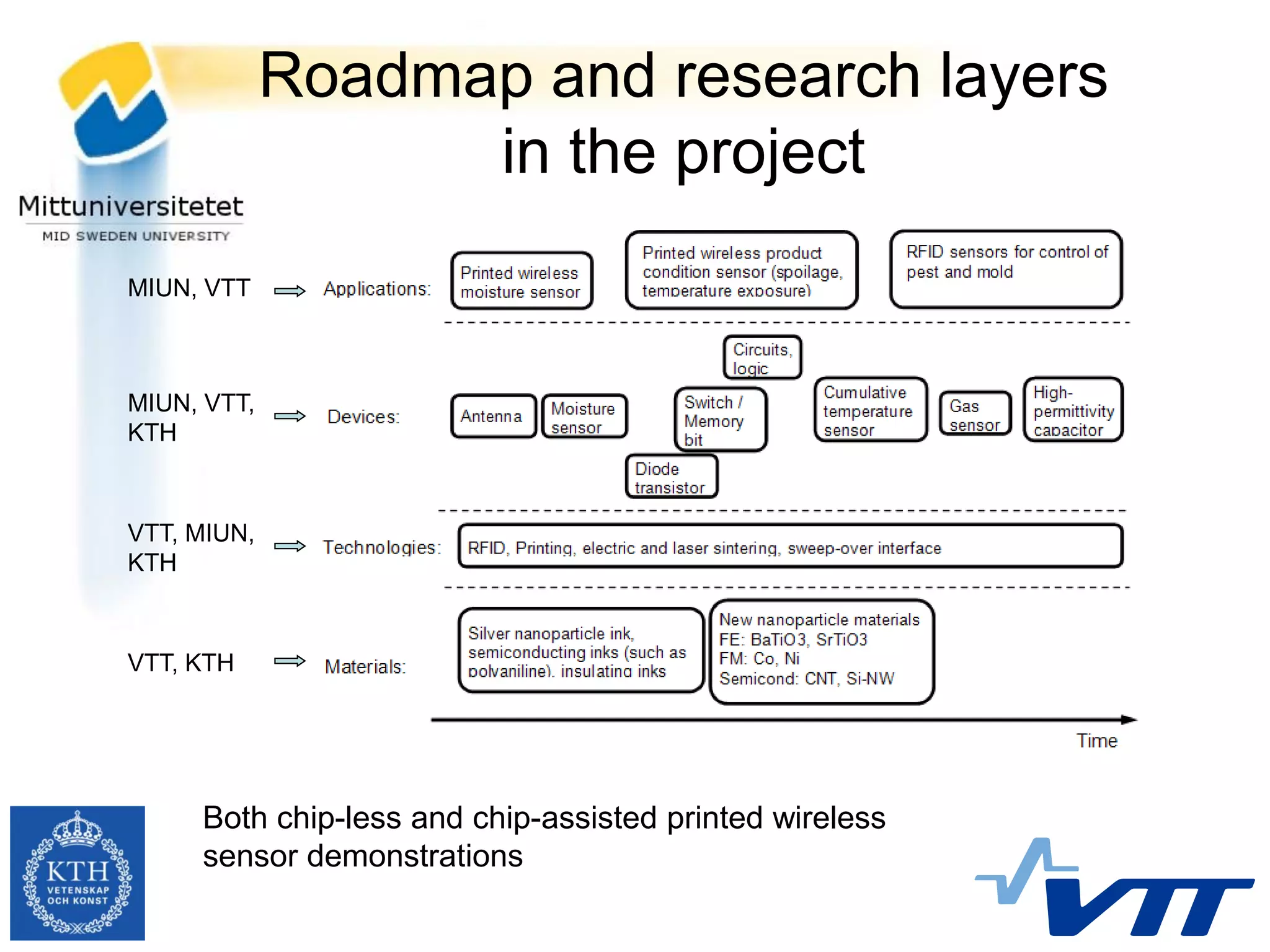

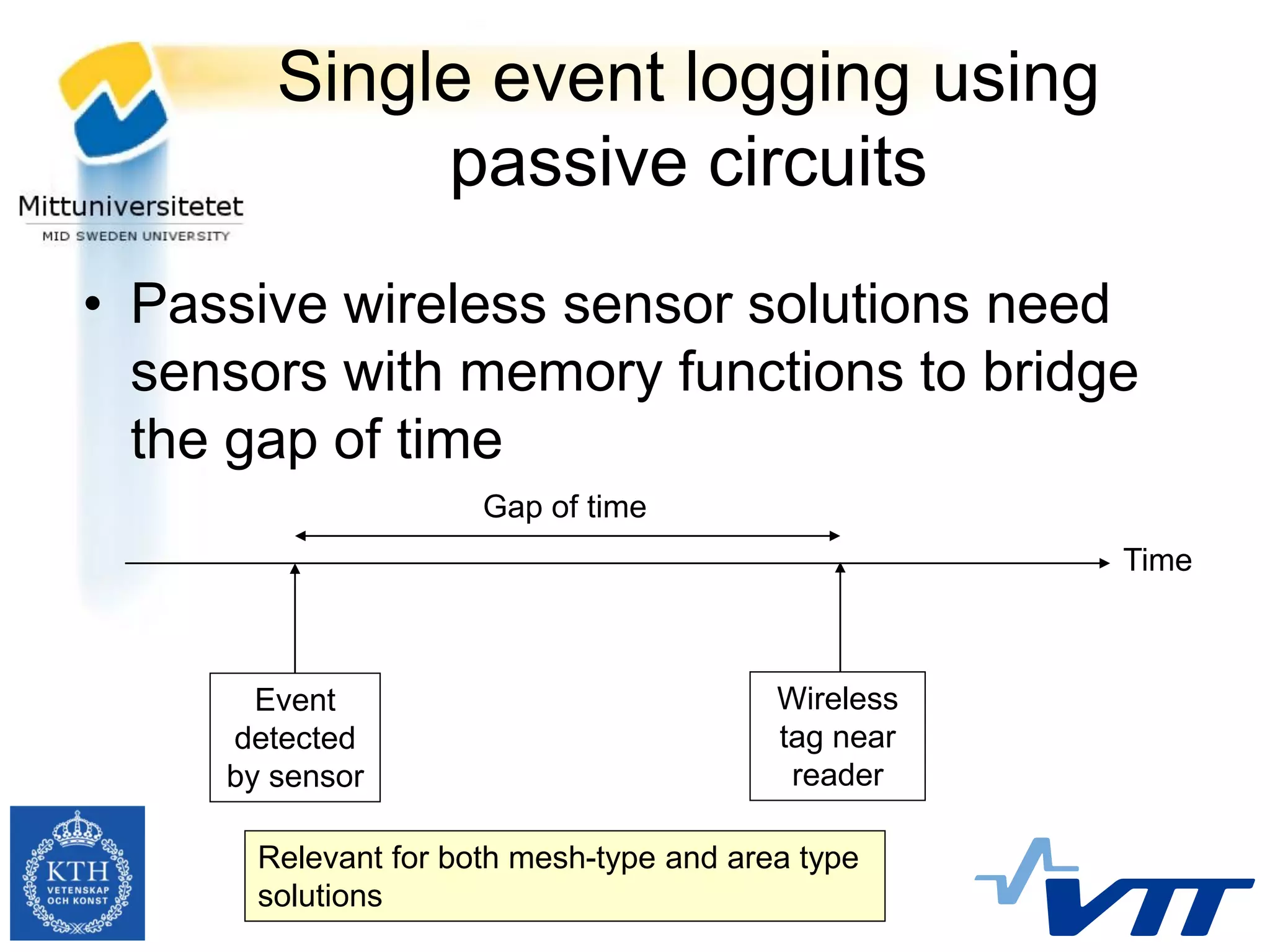

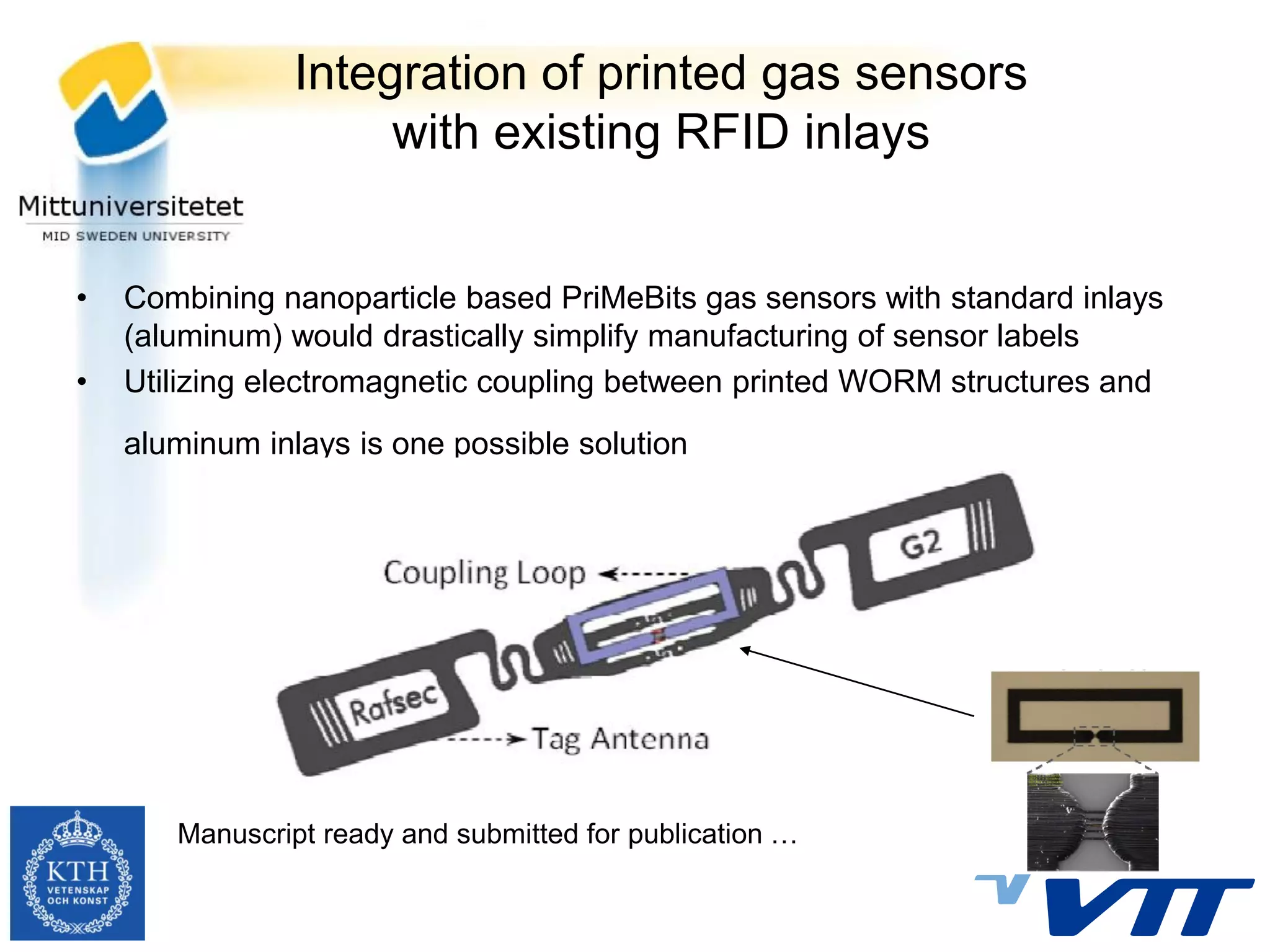

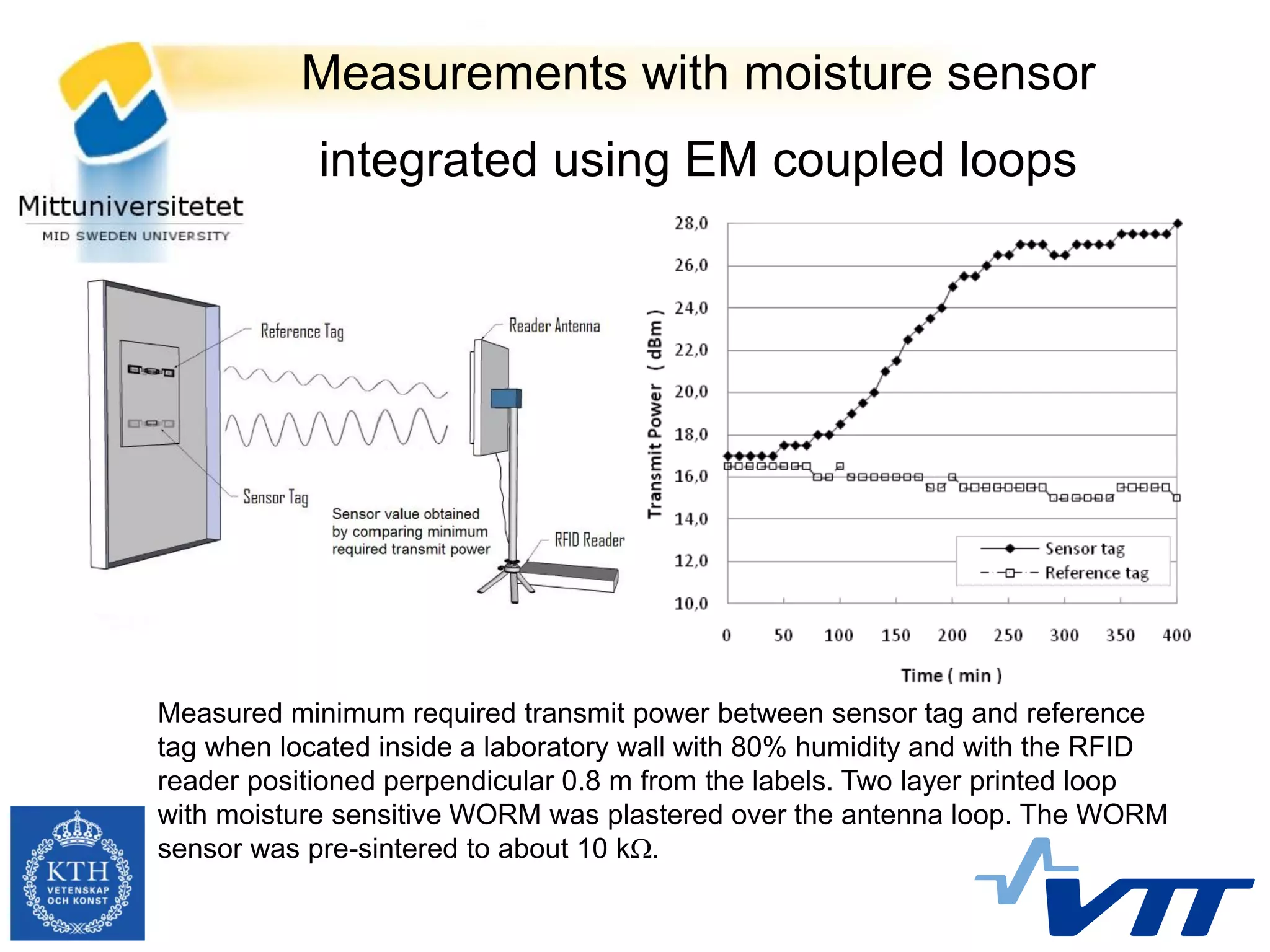

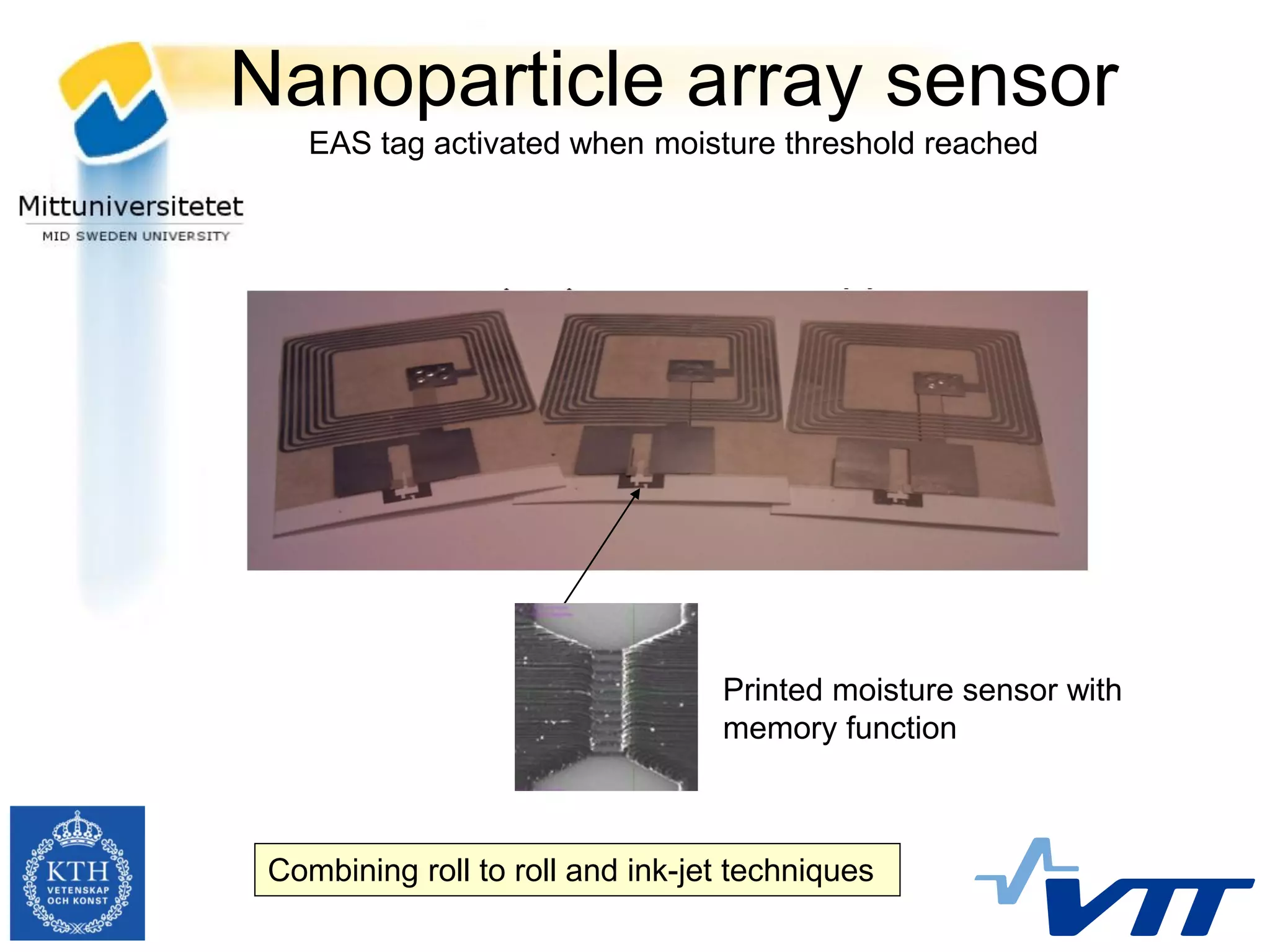

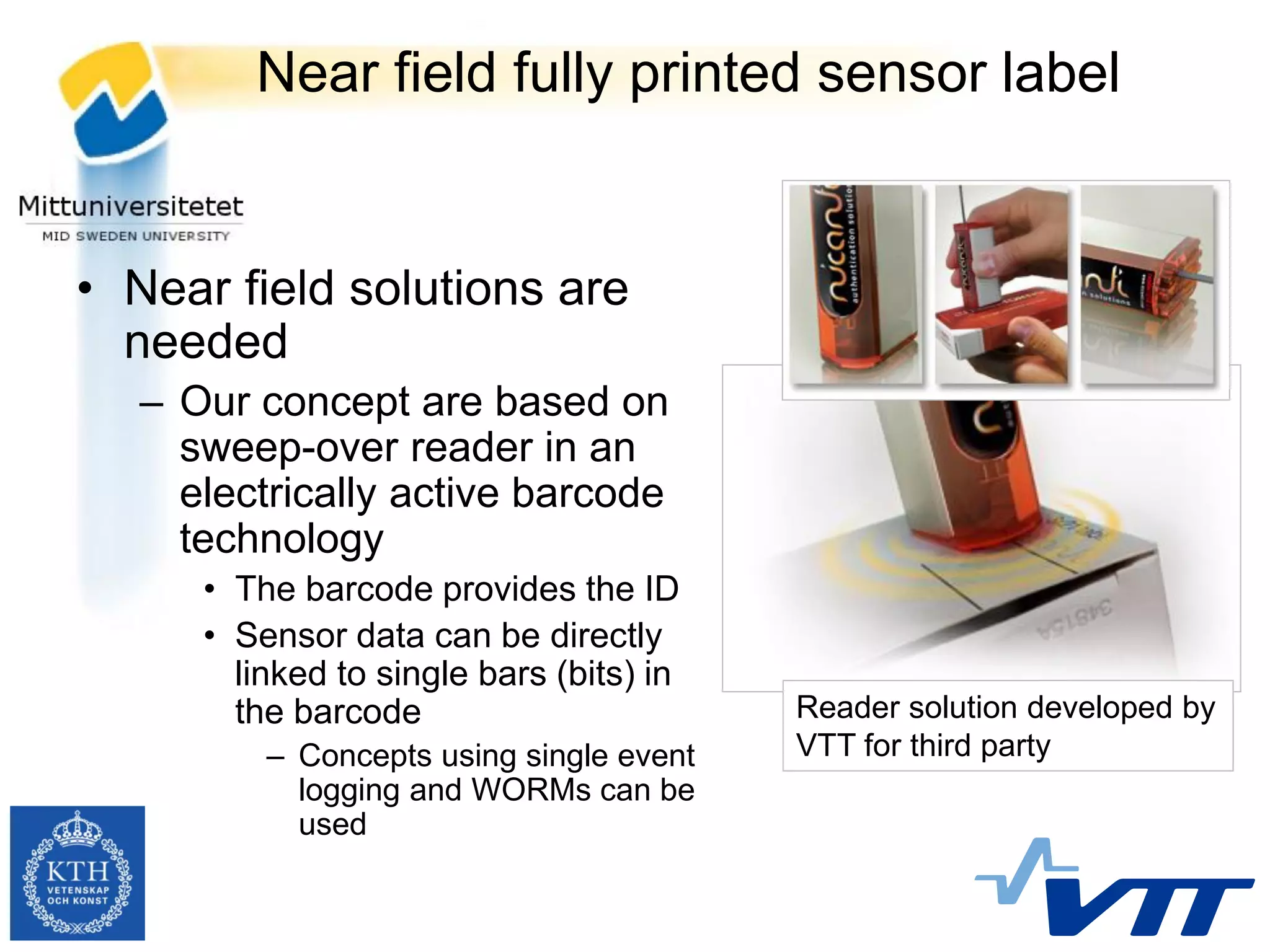

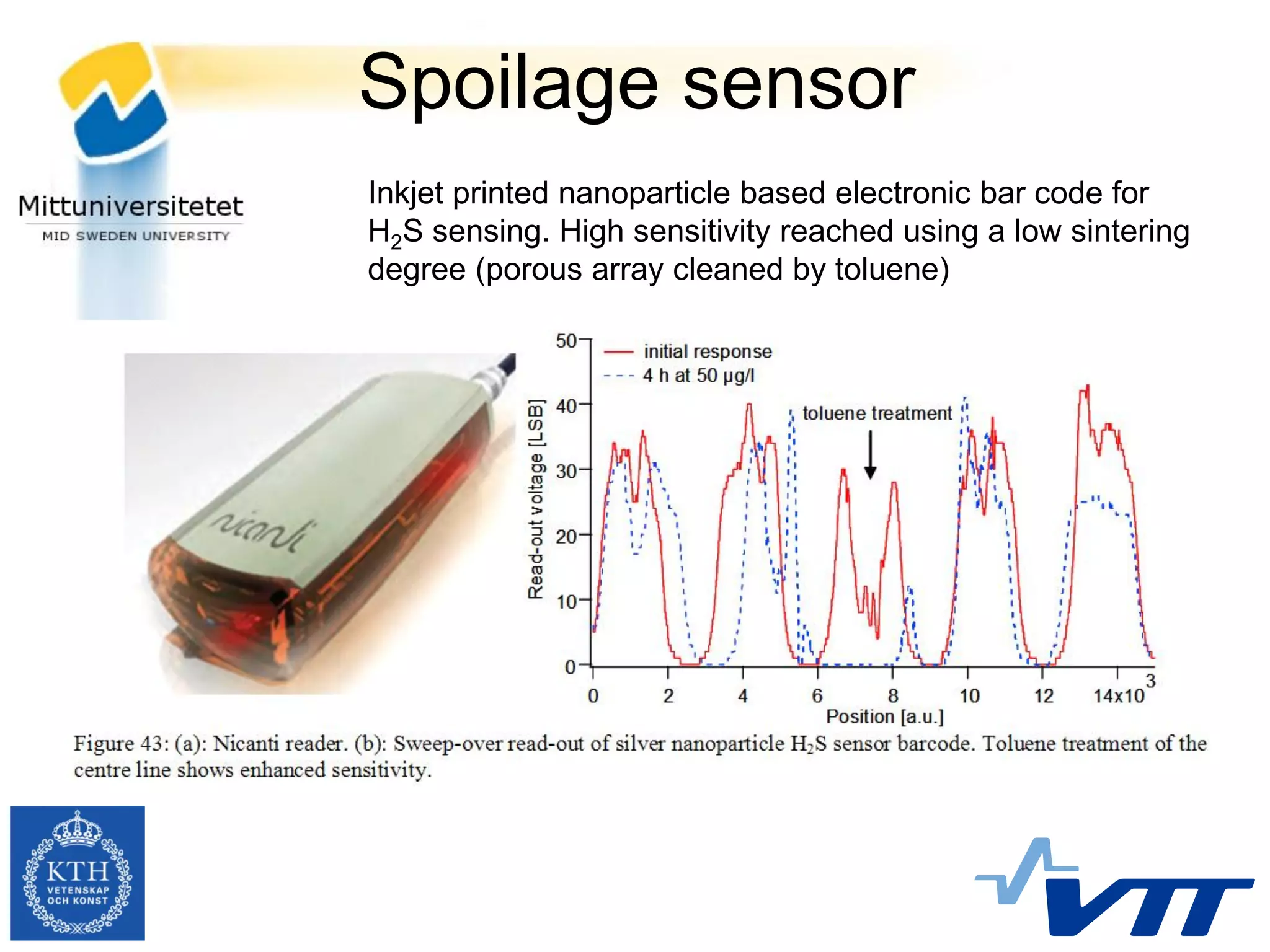

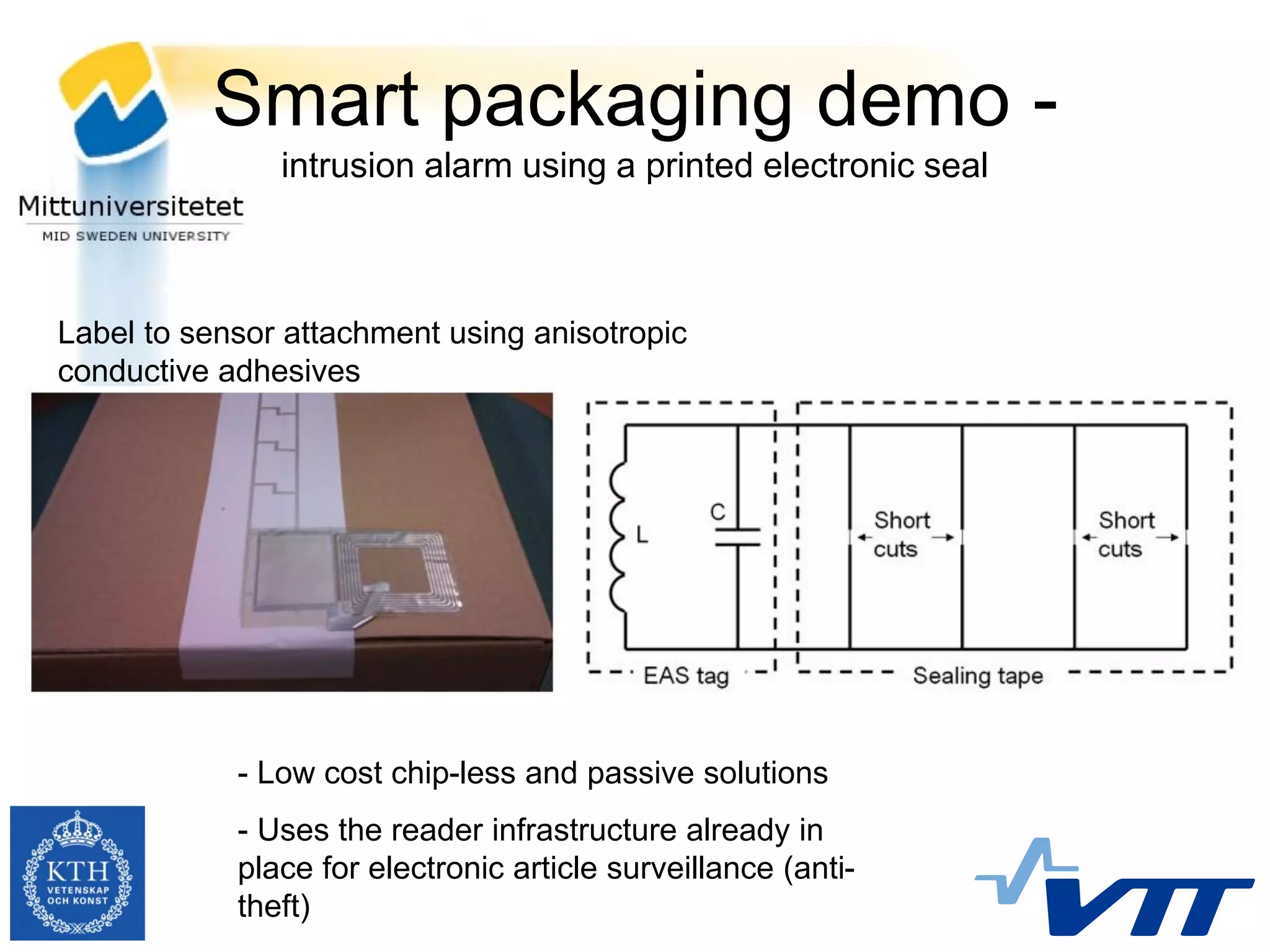

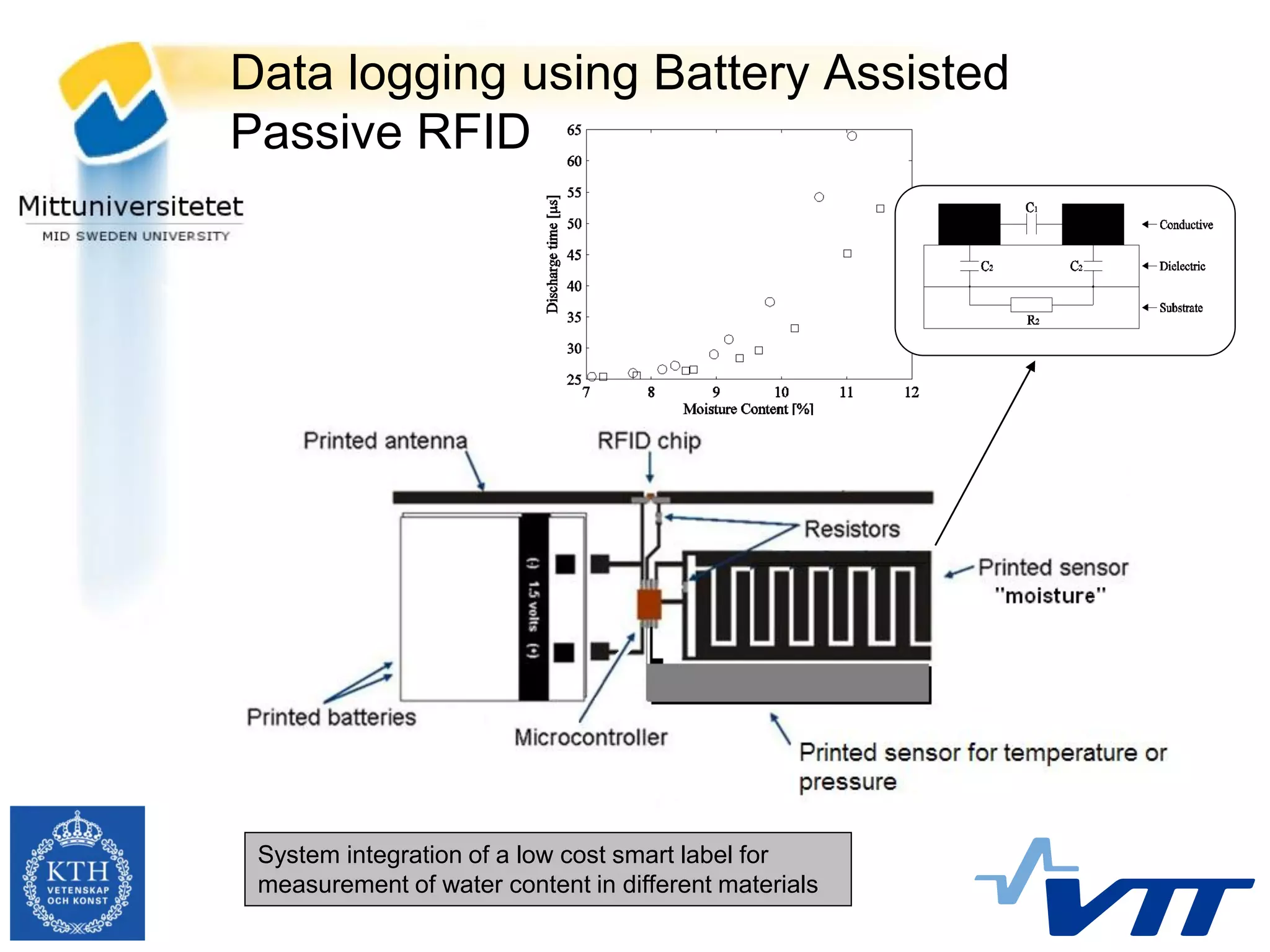

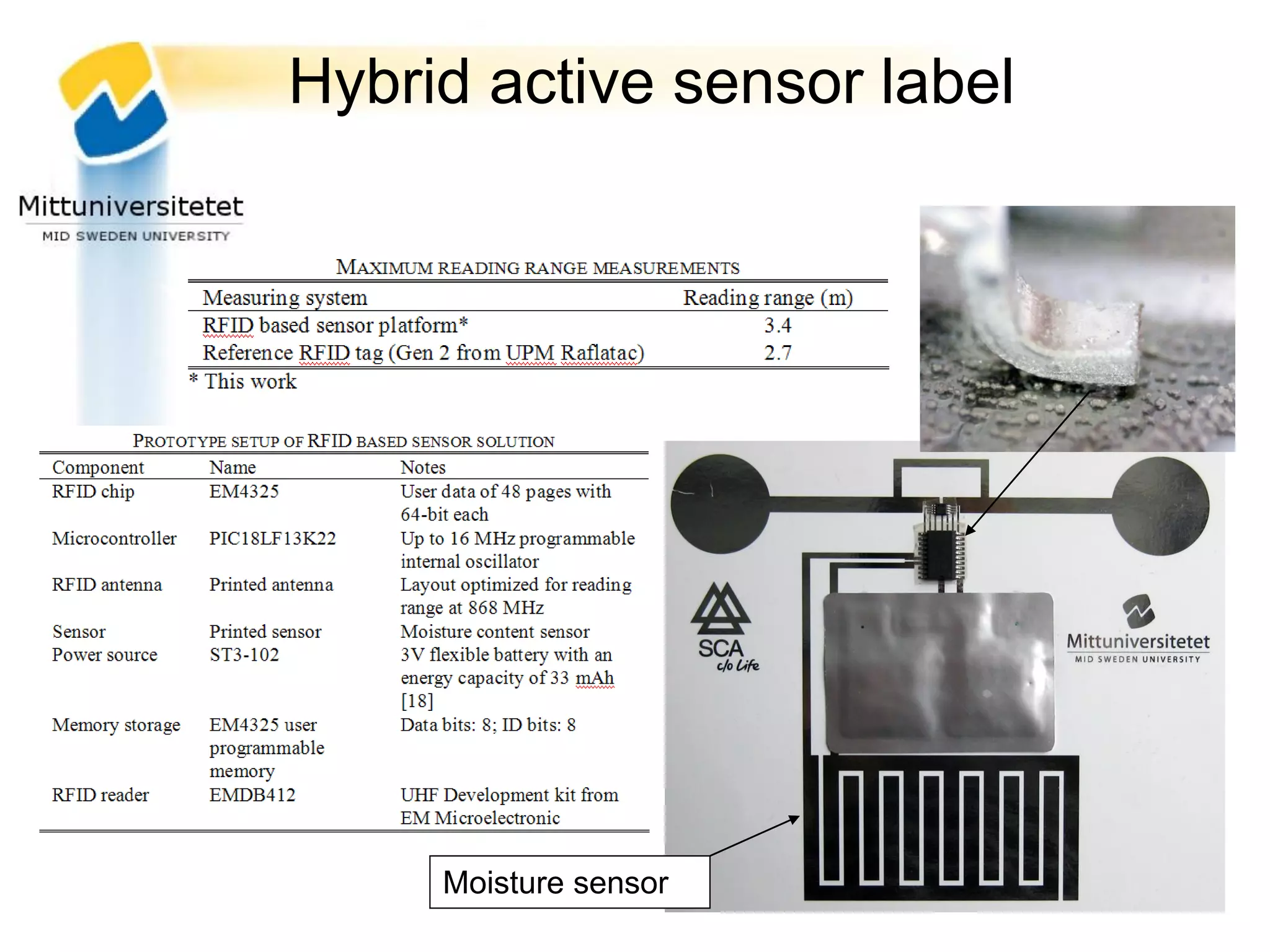

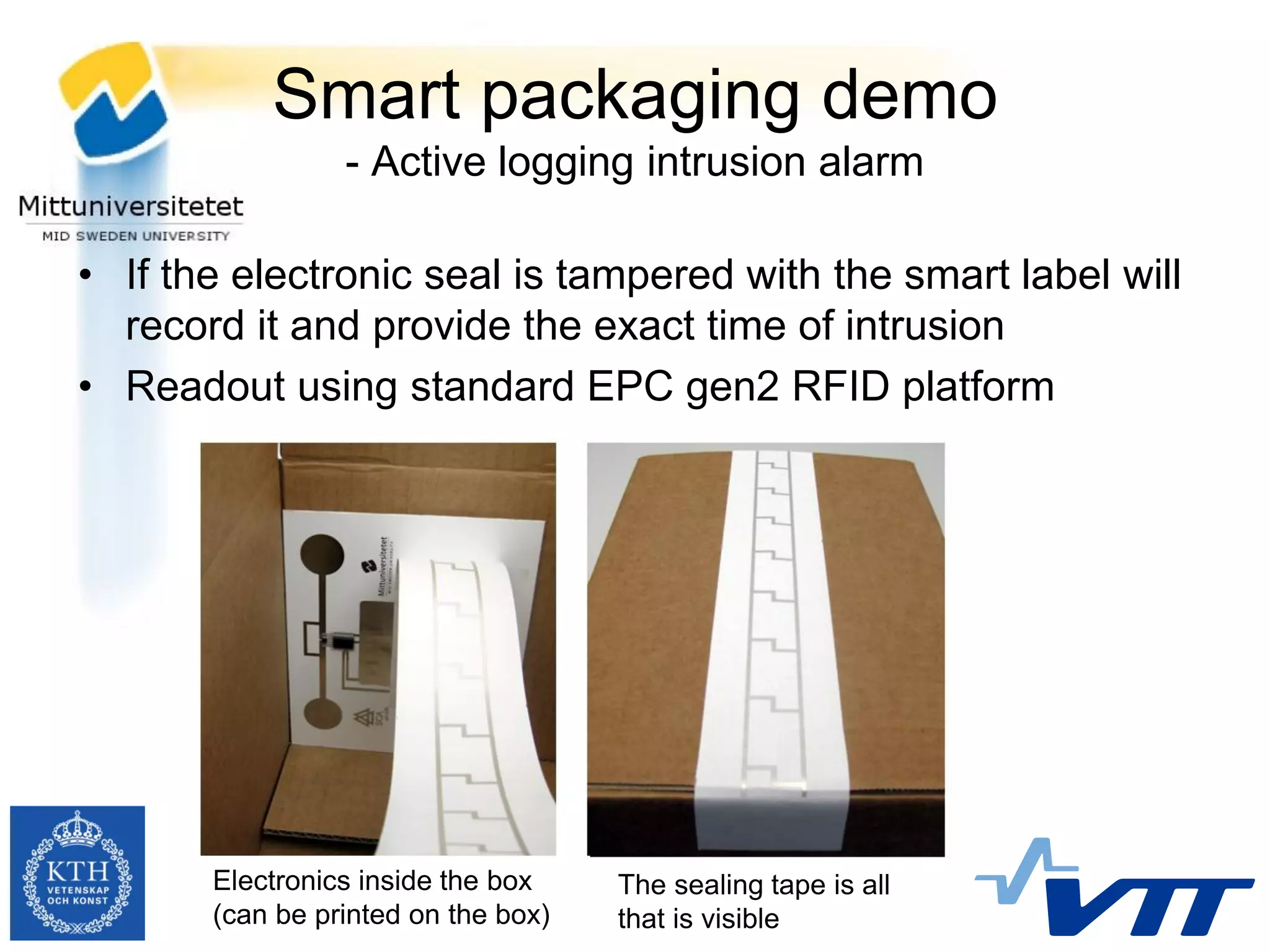

This document discusses the objectives and progress of the Nordite project, which aims to develop printed wireless sensor solutions and RFID tags. The goals are to 1) create tools for integrating printed sensors, logics and wireless communication, 2) develop printed RFID sensors cheaper than EPC tags, and 3) integrate printed sensors into sweep-over and EAS readers. Several demonstrations were created, including moisture and gas sensors integrated with RFID tags to monitor goods. The roadmap included both chipless and chip-assisted sensors. In conclusions, printed sensors and memories were successfully evaluated and integrated with RFID for applications like smart packaging.