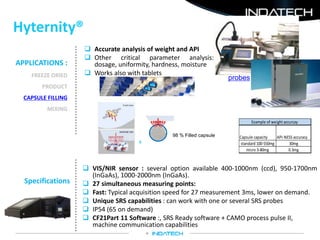

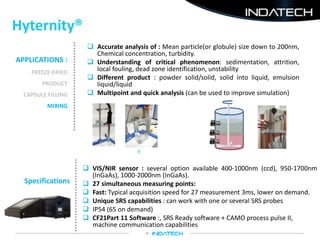

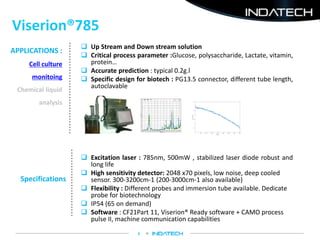

Indatech specializes in designing, building, and selling optical solutions for process development and monitoring, focusing on industries such as pharmaceuticals and biotechnology. The company offers unique patented technologies including spatially resolved spectroscopy (SRS) for real-time chemical and physical property measurement. Established in 2009 and located in Clapiers, France, Indatech's innovations have been validated through collaborations with major multinational companies and are aimed at enhancing process efficiency and safety.