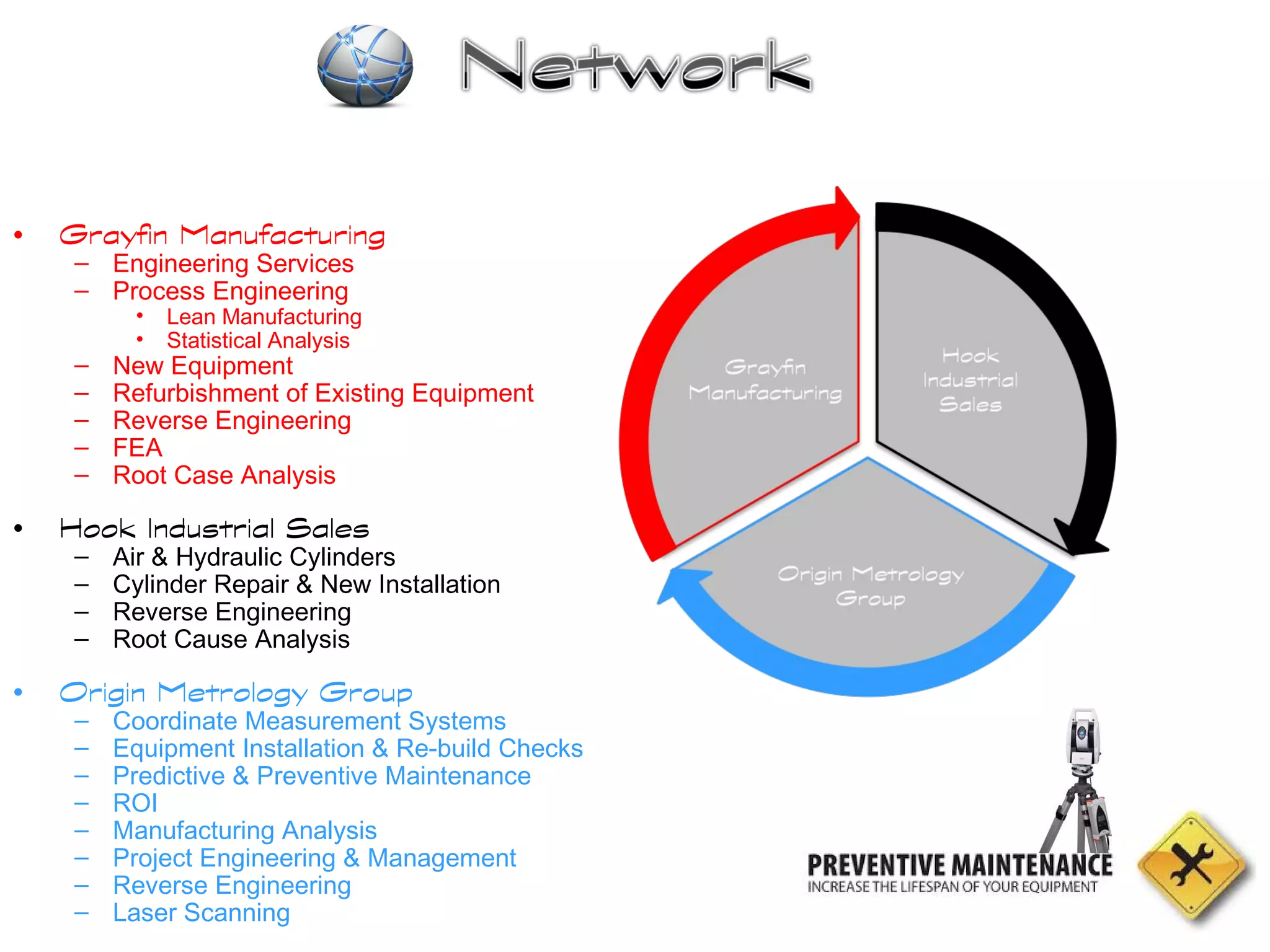

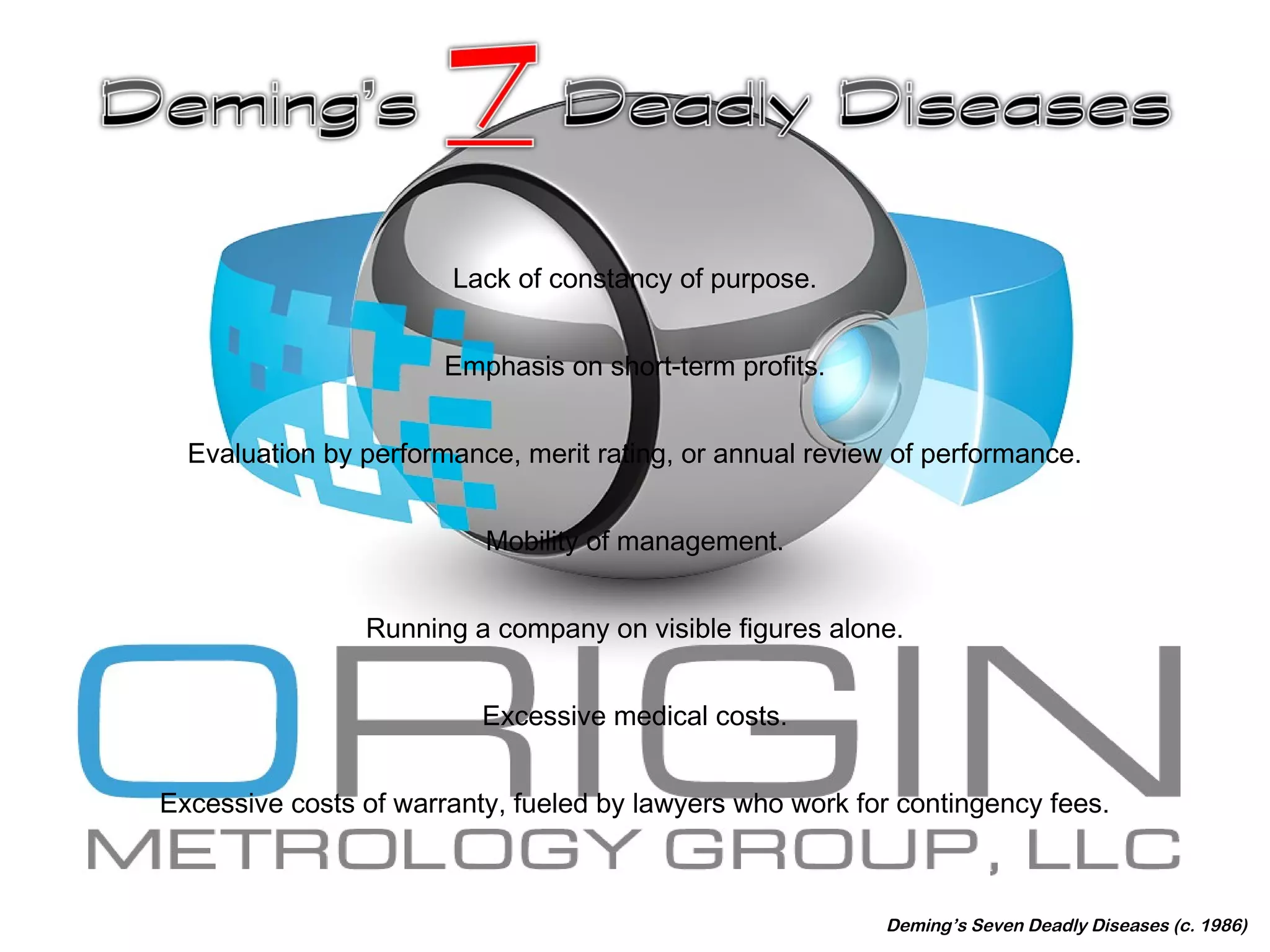

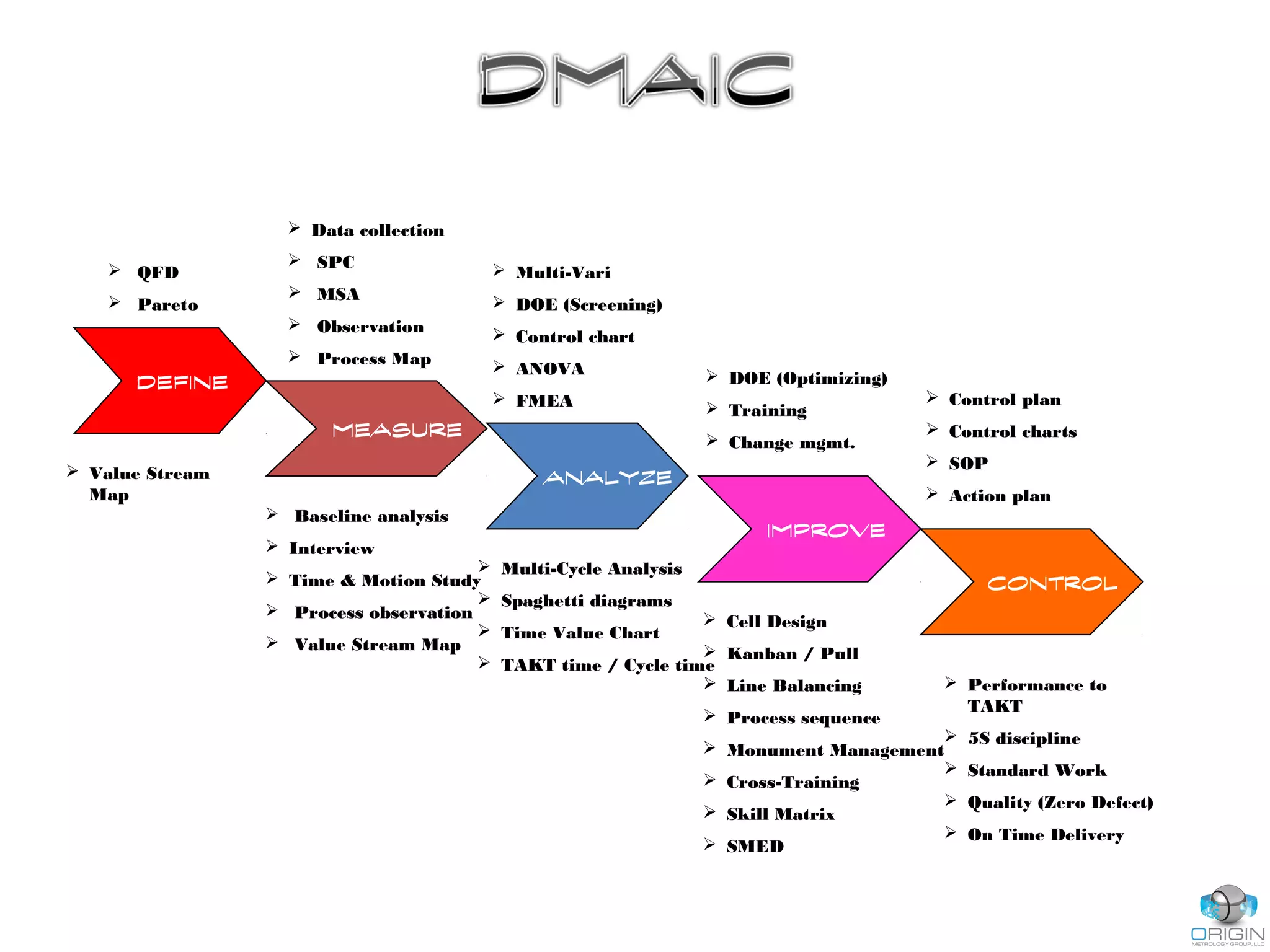

The document outlines the capabilities and philosophy of a network of engineers and professionals focused on providing engineering, manufacturing, and maintenance solutions while emphasizing continuous improvement and reduction of waste through methodologies like Lean Manufacturing and Six Sigma. It highlights the importance of integrating the Theory of Constraints and utilizing project management techniques to enhance organizational efficiency and achieve customer satisfaction. Additionally, it stresses the commitment to ongoing education and the application of Dr. W. Edwards Deming's principles in fostering a culture of excellence and innovation.