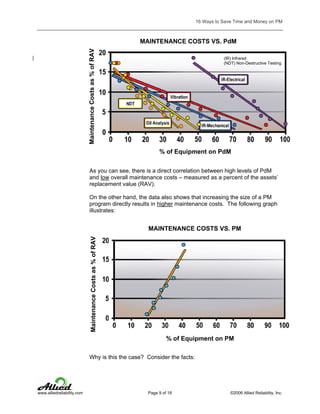

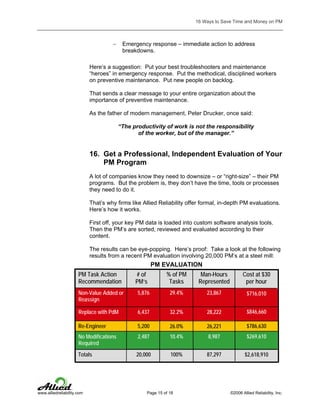

This document provides 16 ways to save time and money on preventive maintenance programs. It suggests that many PM programs are larger than needed and consume too many resources while still resulting in unexpected equipment failures. It recommends first considering predictive maintenance technologies before adding more PMs. Other tips include removing unnecessary PMs, questioning if PMs actually help productivity, getting data from PMs that can be trended over time, and ensuring PMs are completed within 10% of their scheduled due date. The goal of PM should be to detect small problems to plan repairs, not just prevent failures.