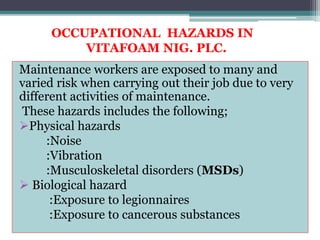

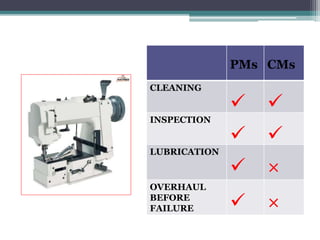

The document discusses maintenance and occupational safety. It defines maintenance as actions taken to retain or restore equipment to a working state. Preventive maintenance aims to avoid failures through scheduled repairs and is more cost effective than corrective maintenance, which only fixes existing issues. The document also outlines various occupational hazards for maintenance workers like noise, vibration, and exposure to hazardous substances. It recommends enforcing protective equipment, risk assessments, safety information, and injury prevention programs to promote occupational safety.

![COST OF MAINTENANCE ON CAPITAL

INVESTMENT RETURN

The cost of maintenance can send your business

broke. If your annual maintenance cost is higher

than 5% of your asset value you are in trouble.

Total Maintenance Cost per RAV (%) = [Total

Maintenance Cost ($) × 100] ÷ Replacement Asset

Value ($)

The total maintenance cost depends on the quality

of the equipment used and how much

maintenance it requires.](https://image.slidesharecdn.com/185e549a-b534-4e35-a459-aaa802c906ed-161219143051/85/MAINTENANCE-AND-OCCUPATIONAL-SAFETY-17-320.jpg)