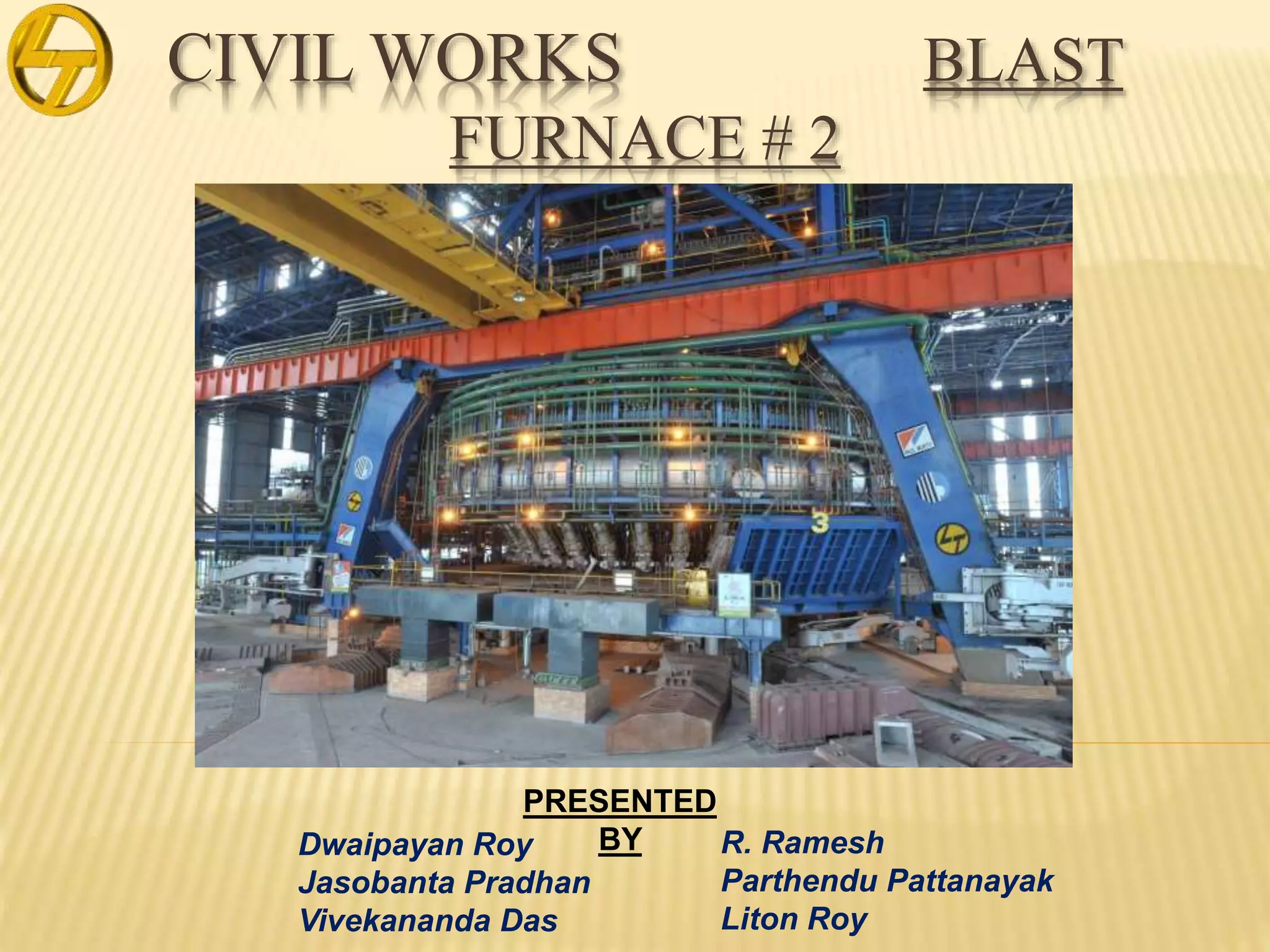

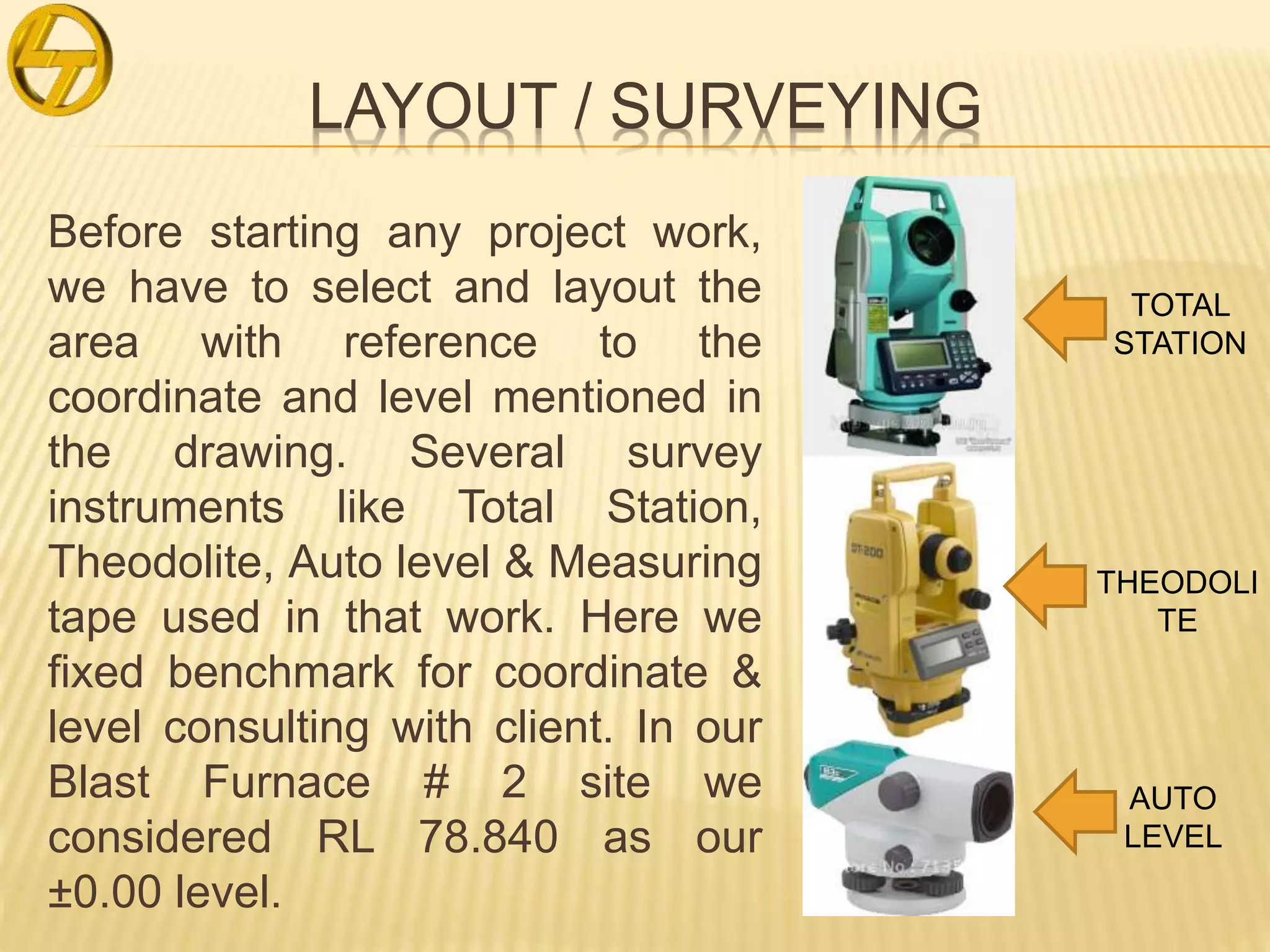

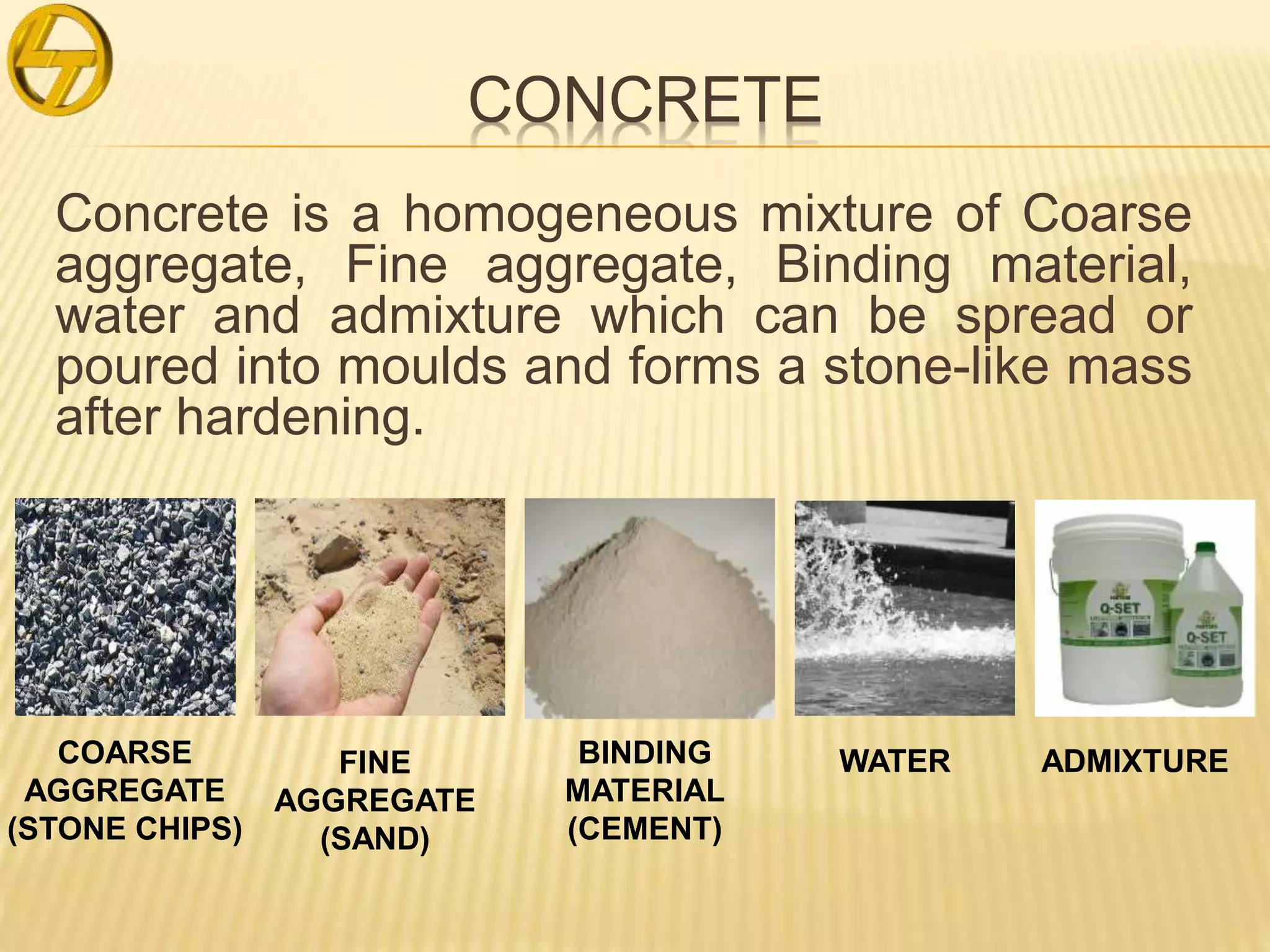

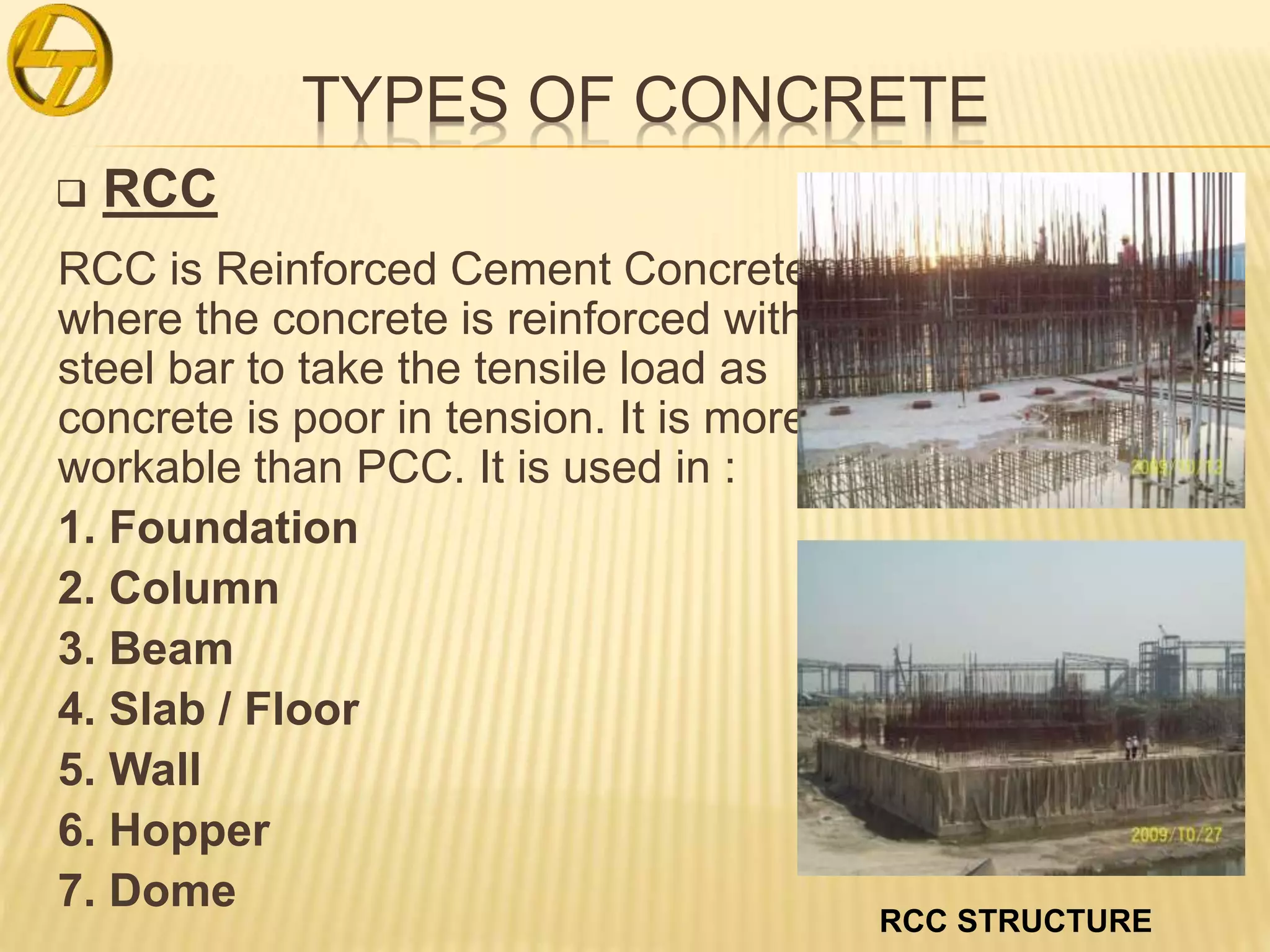

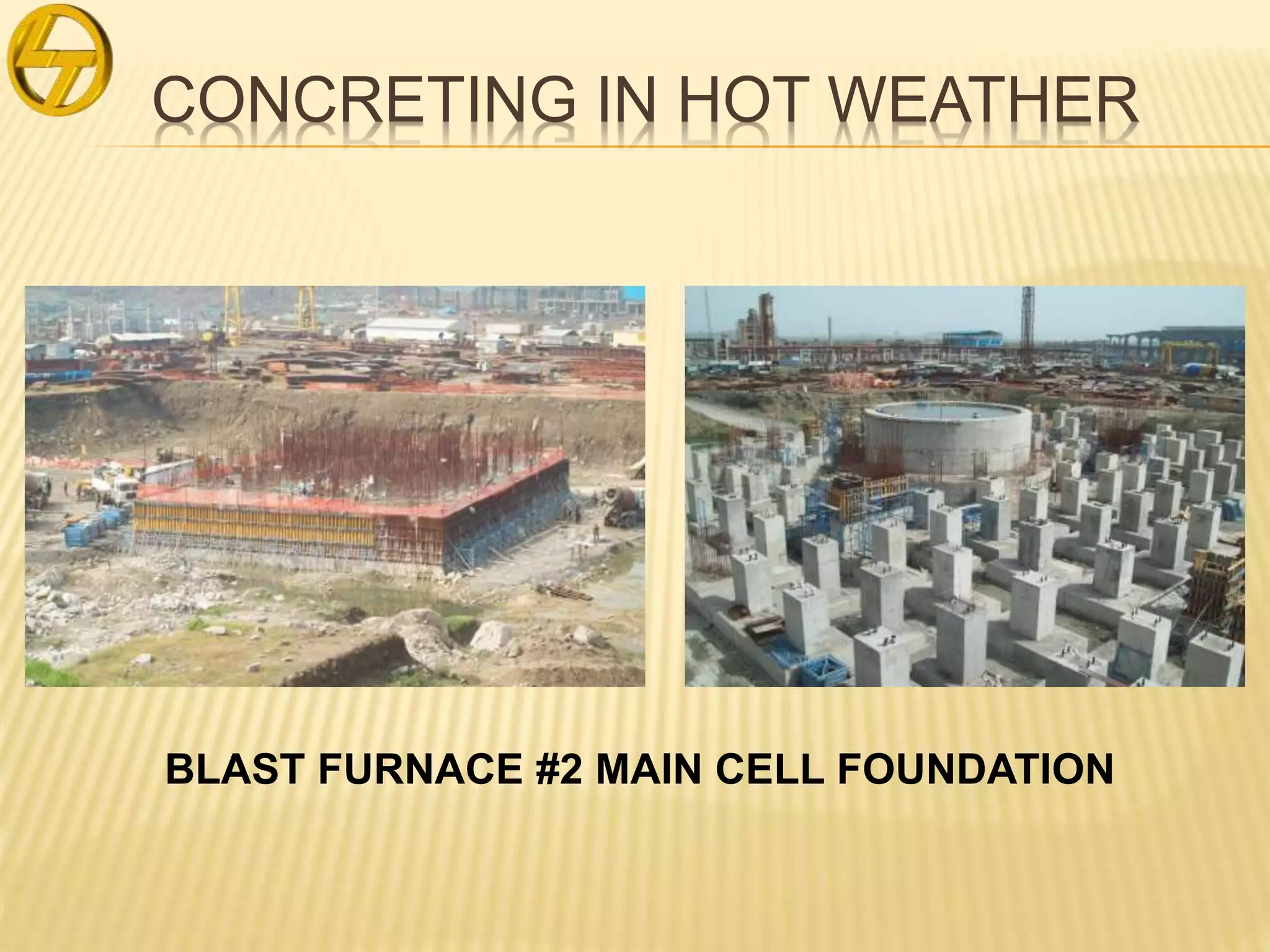

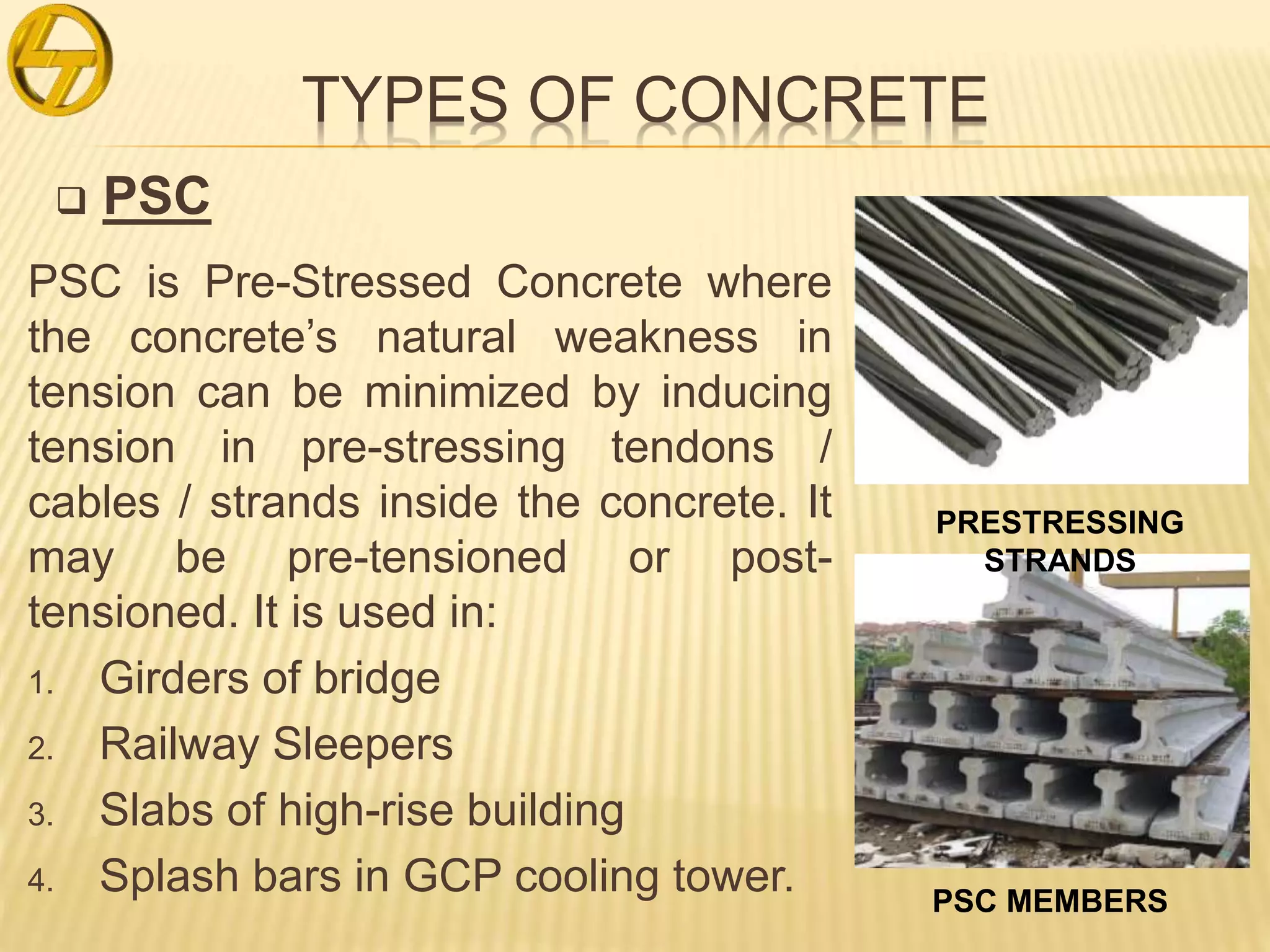

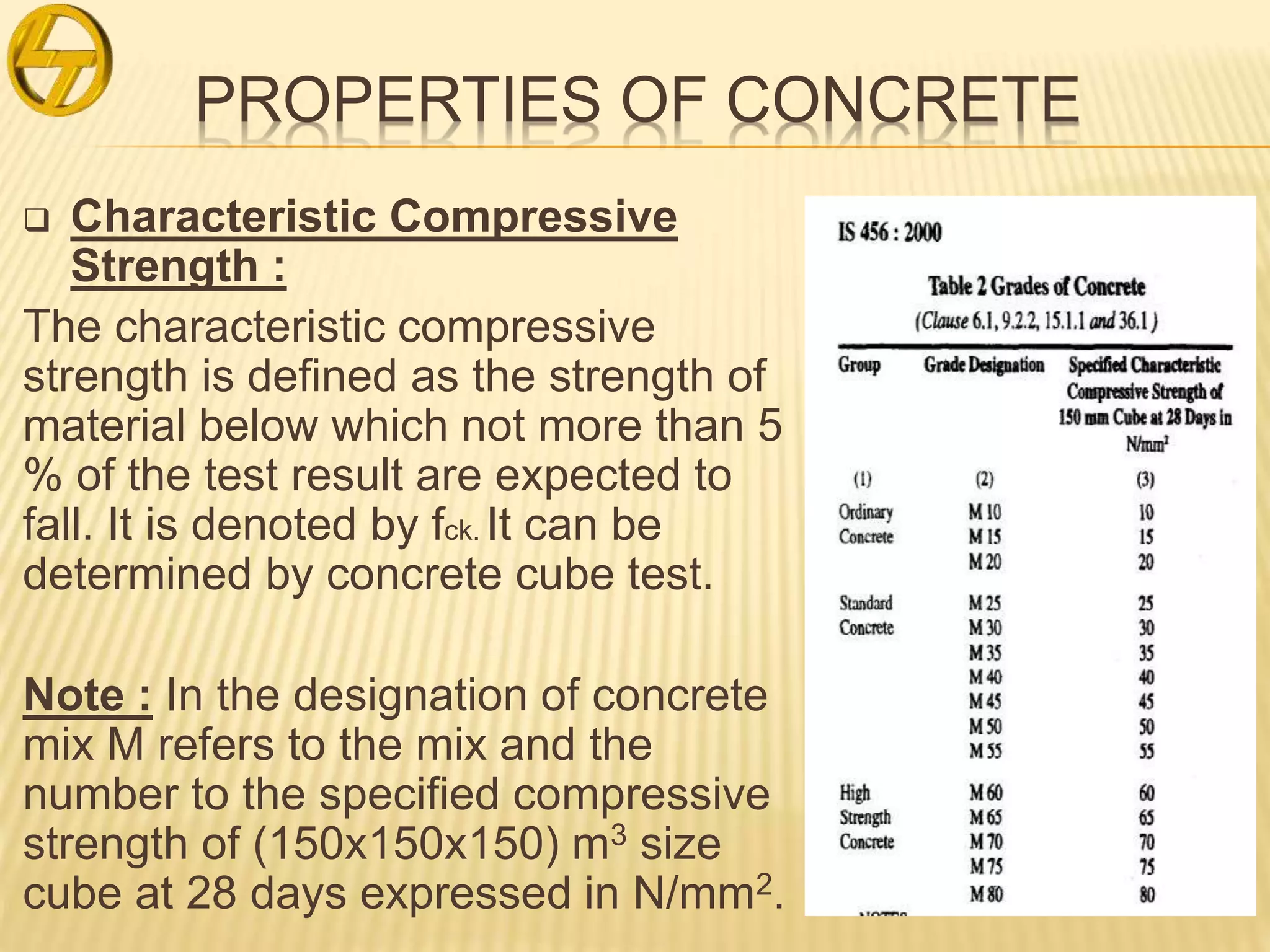

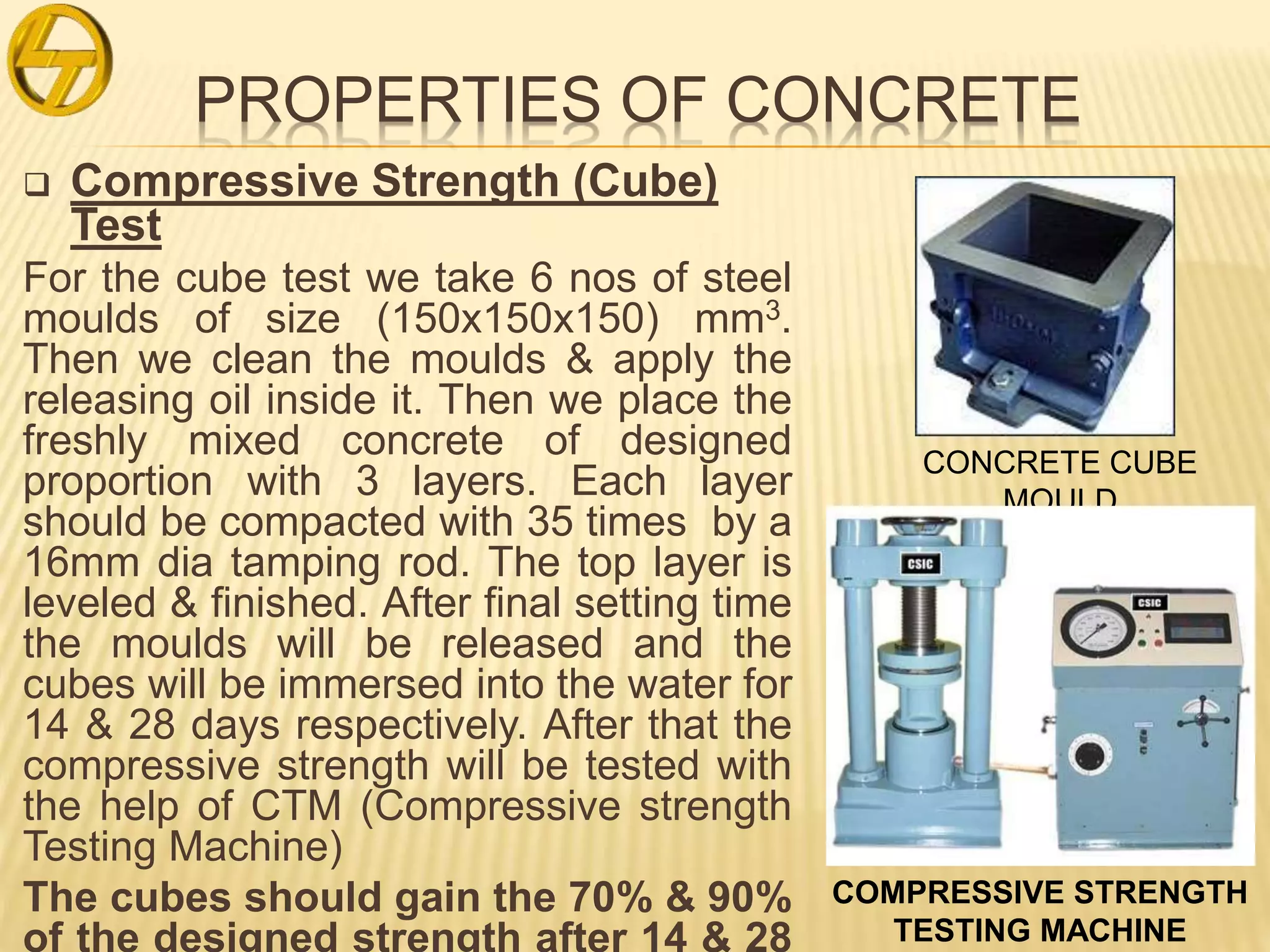

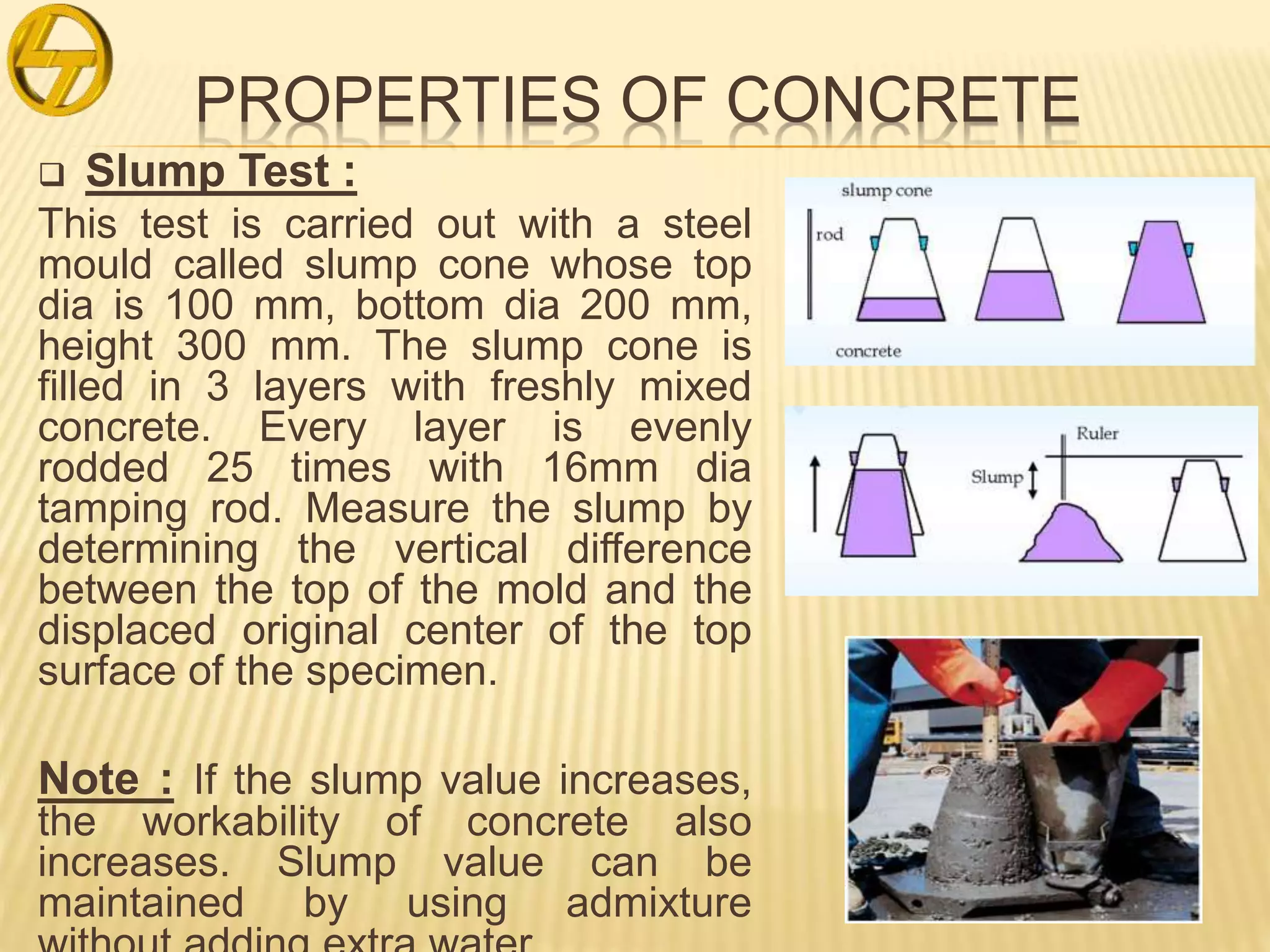

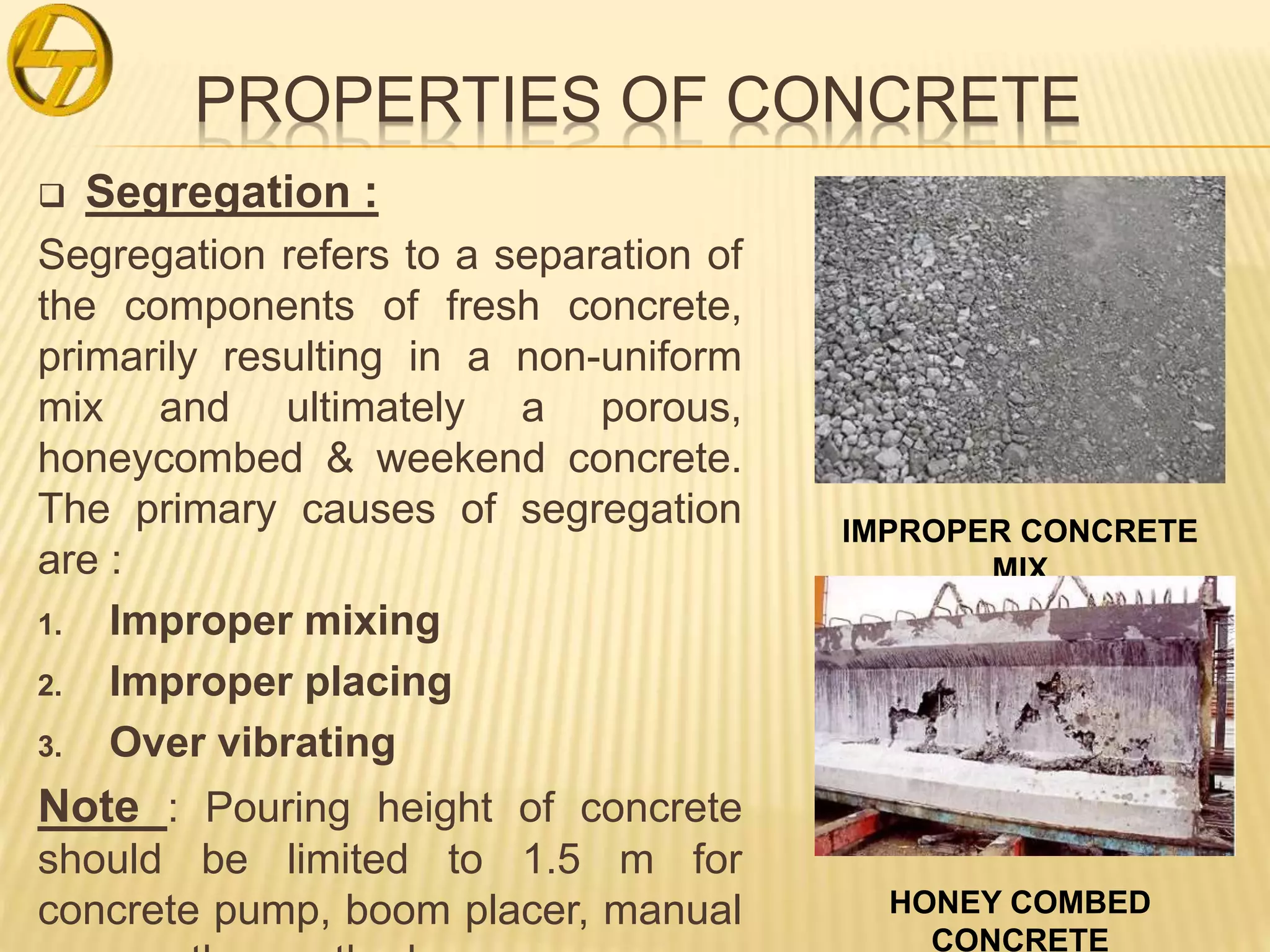

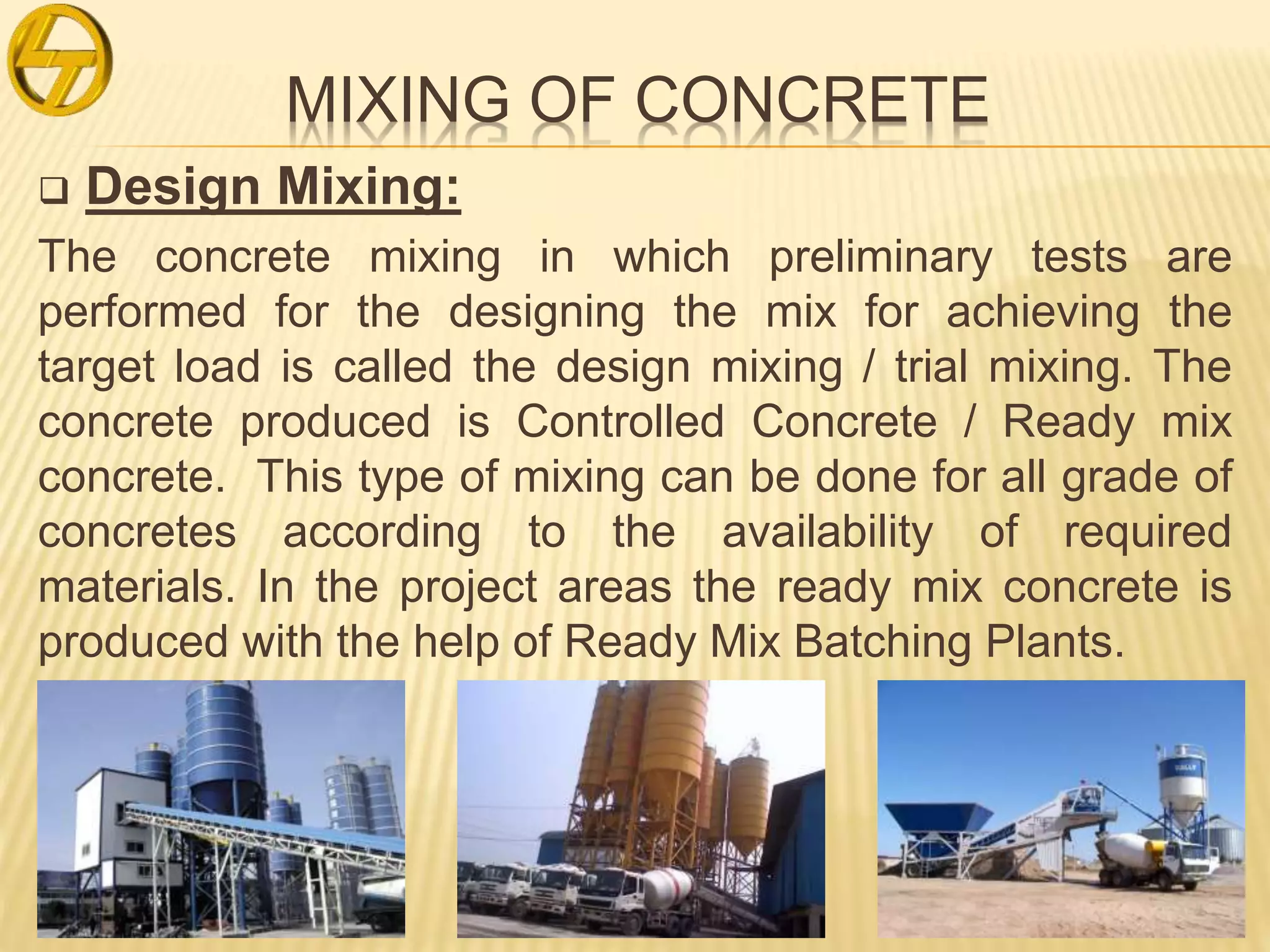

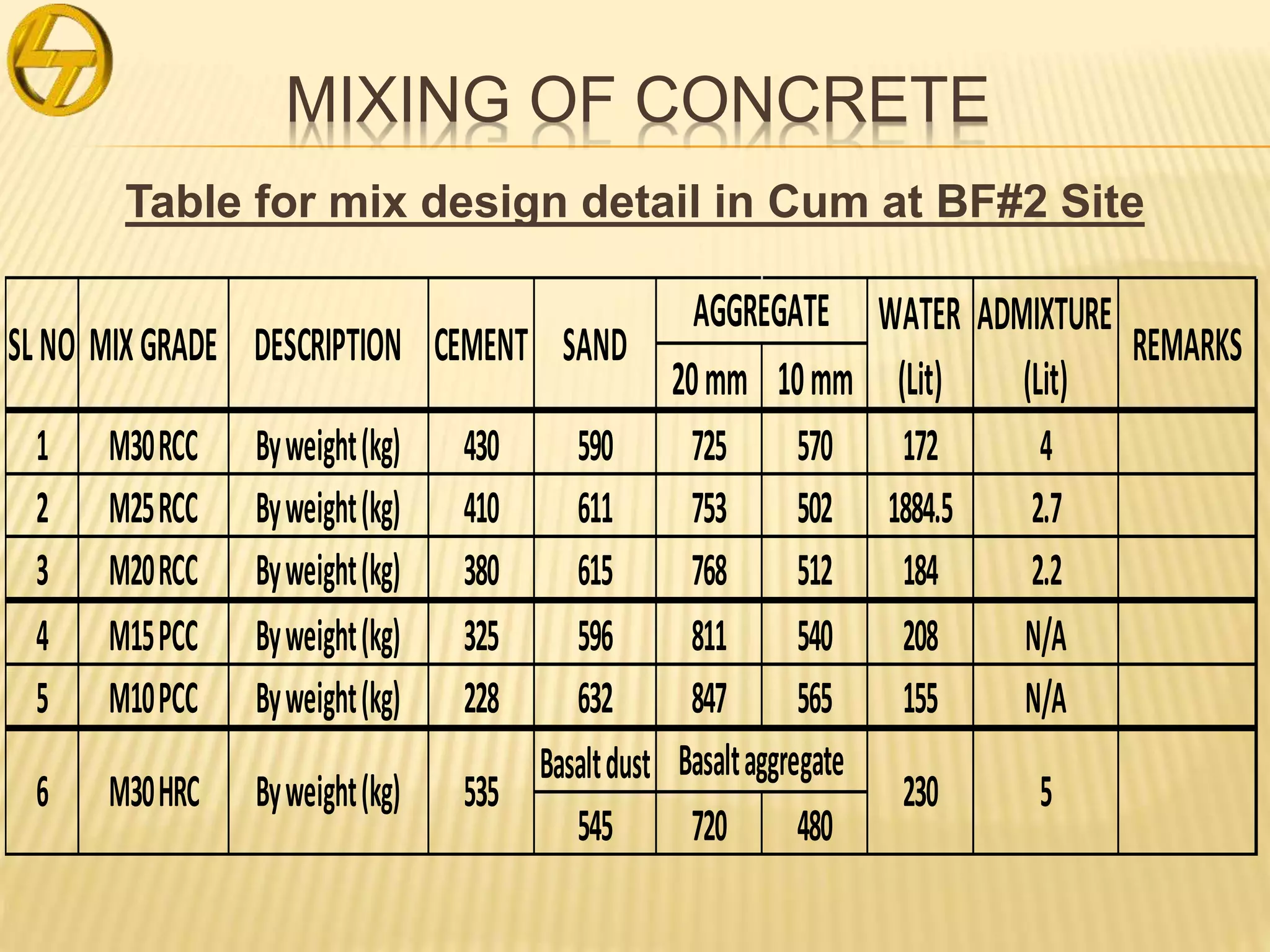

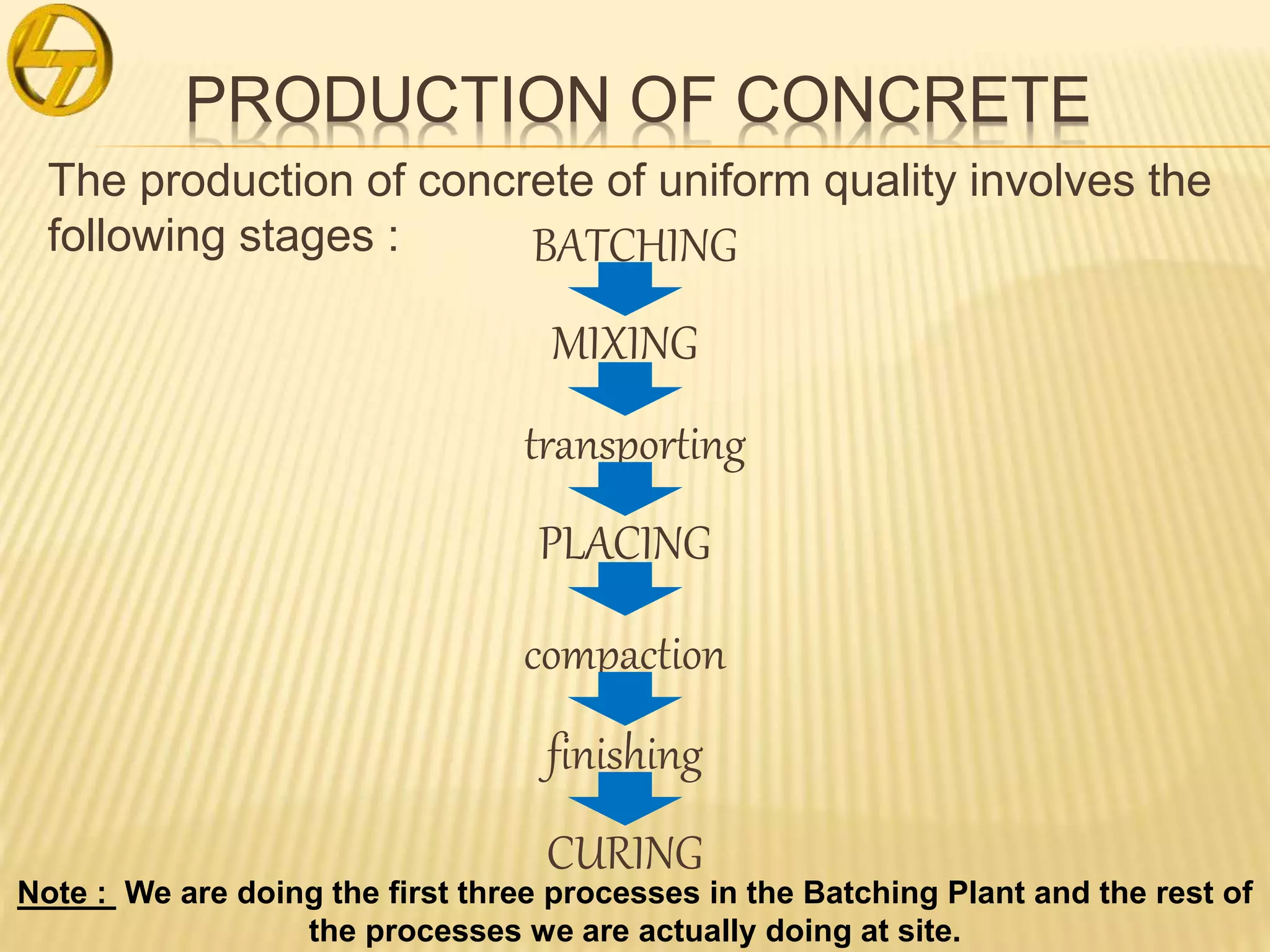

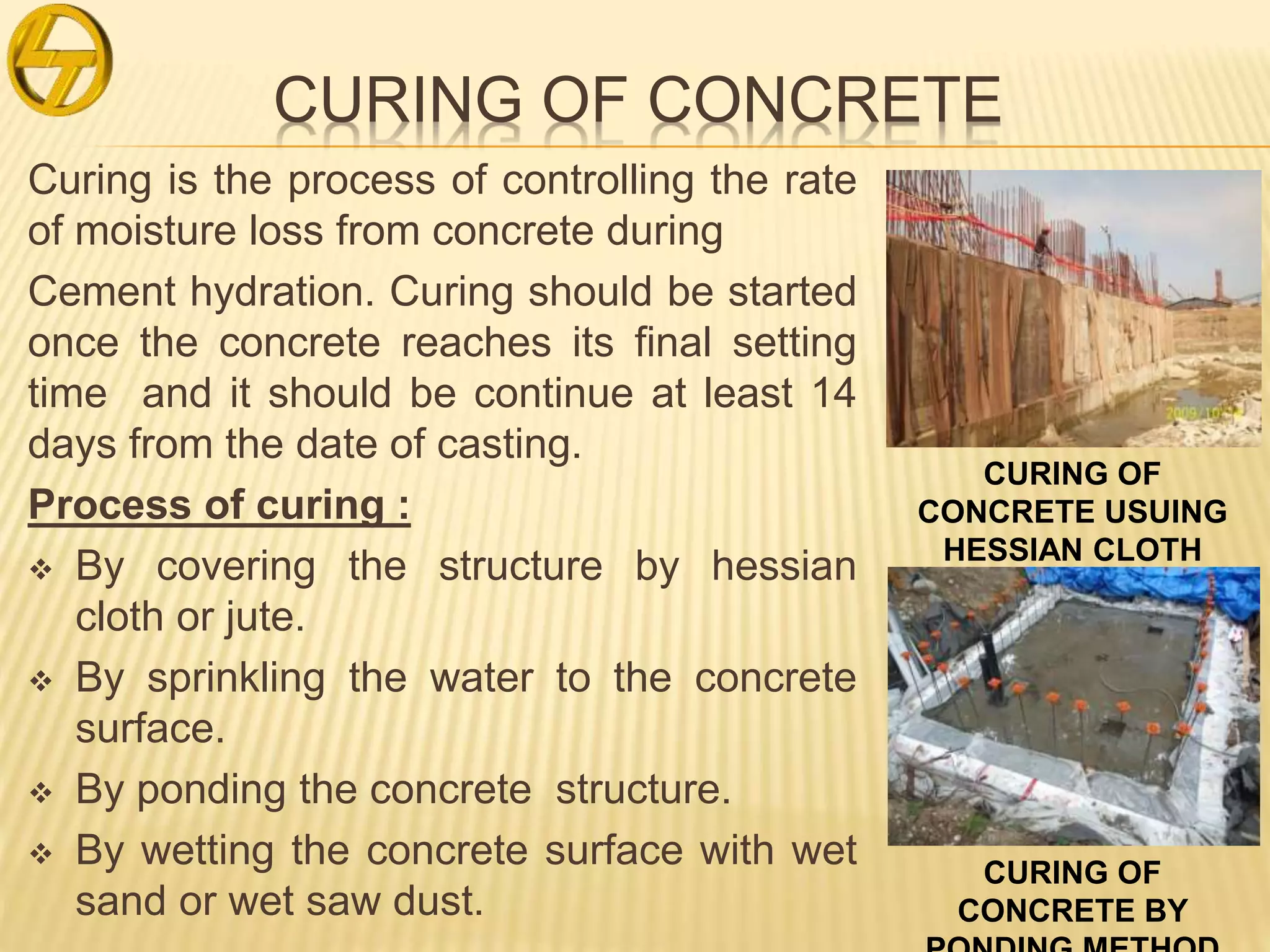

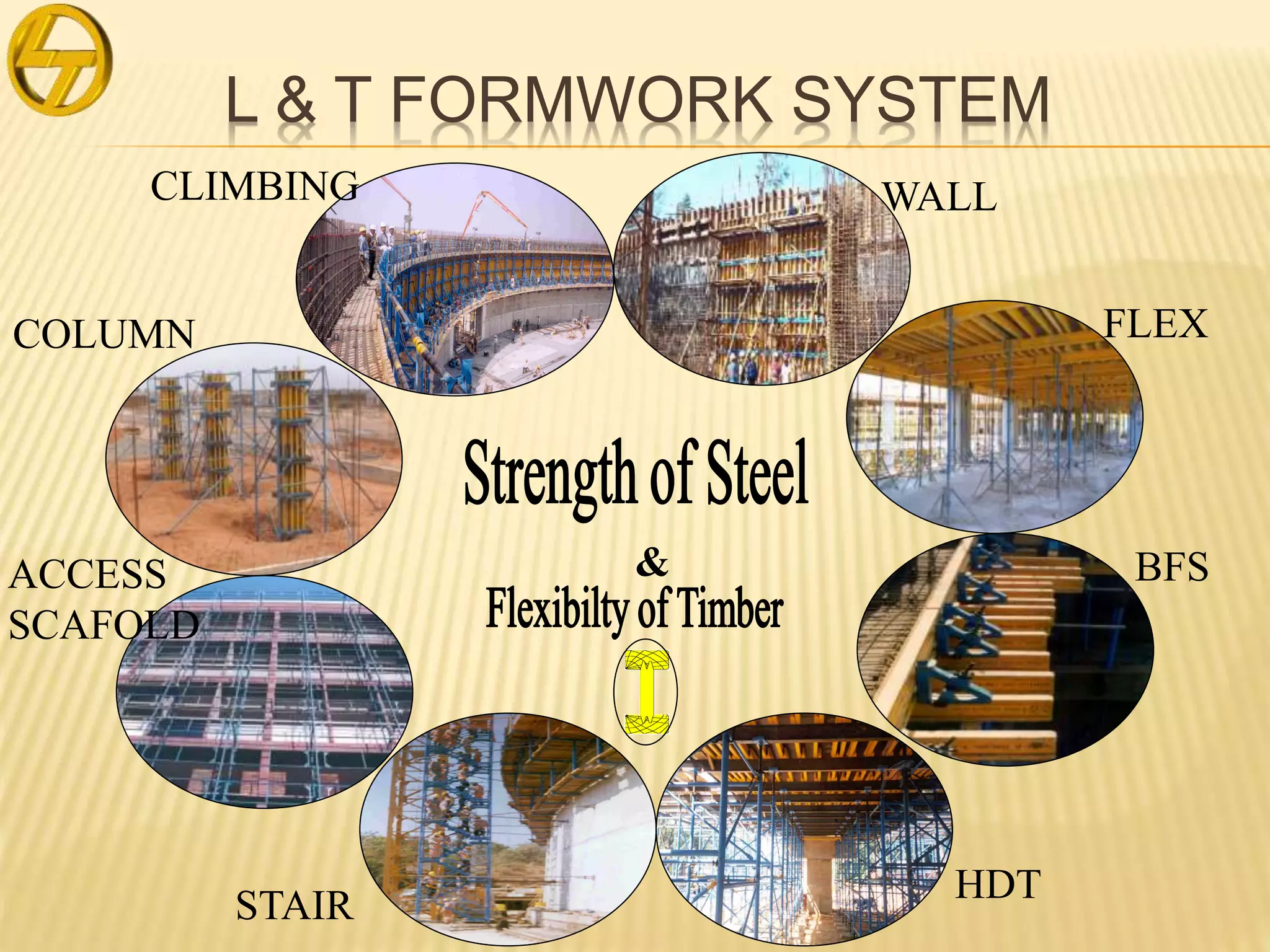

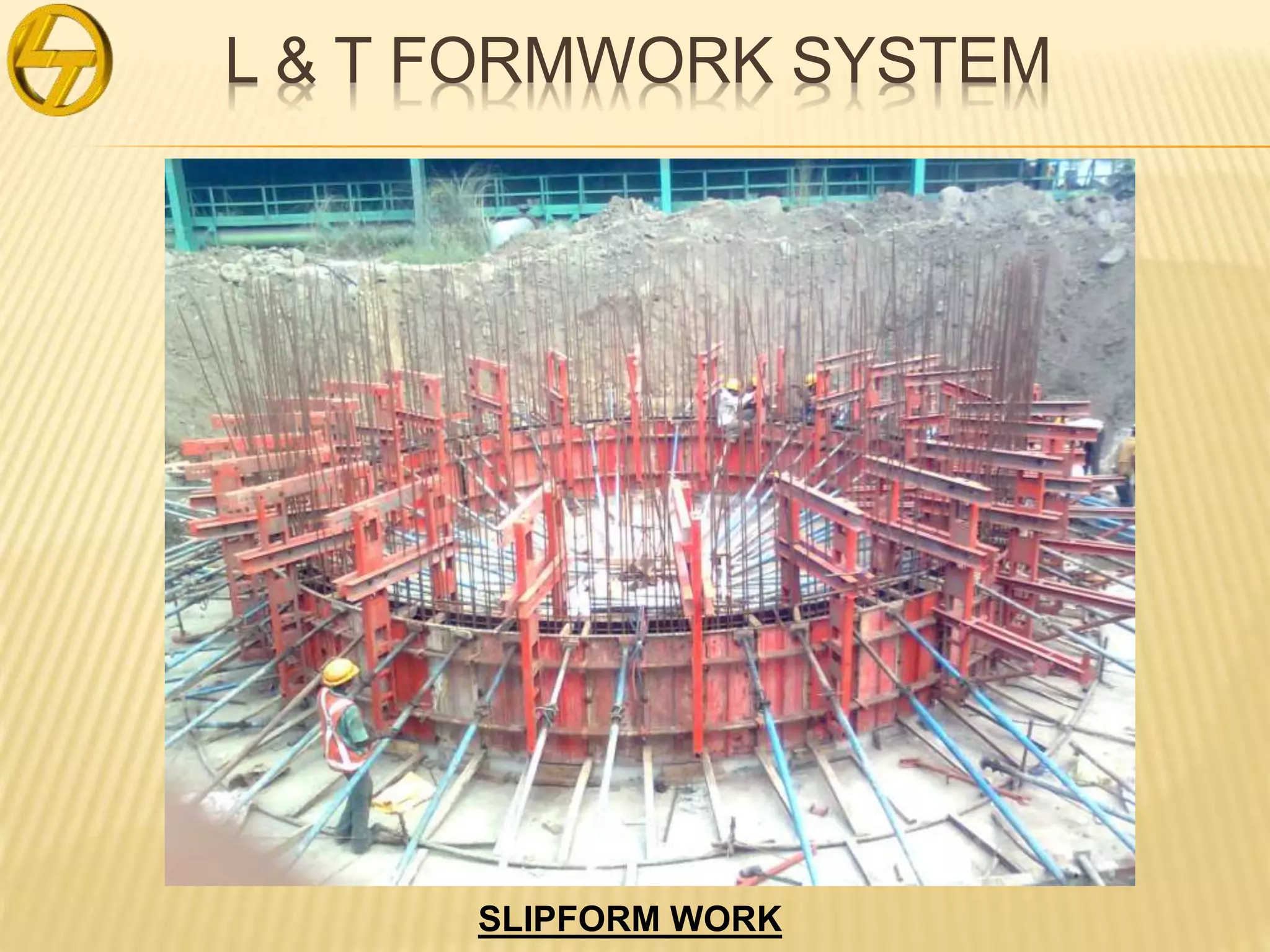

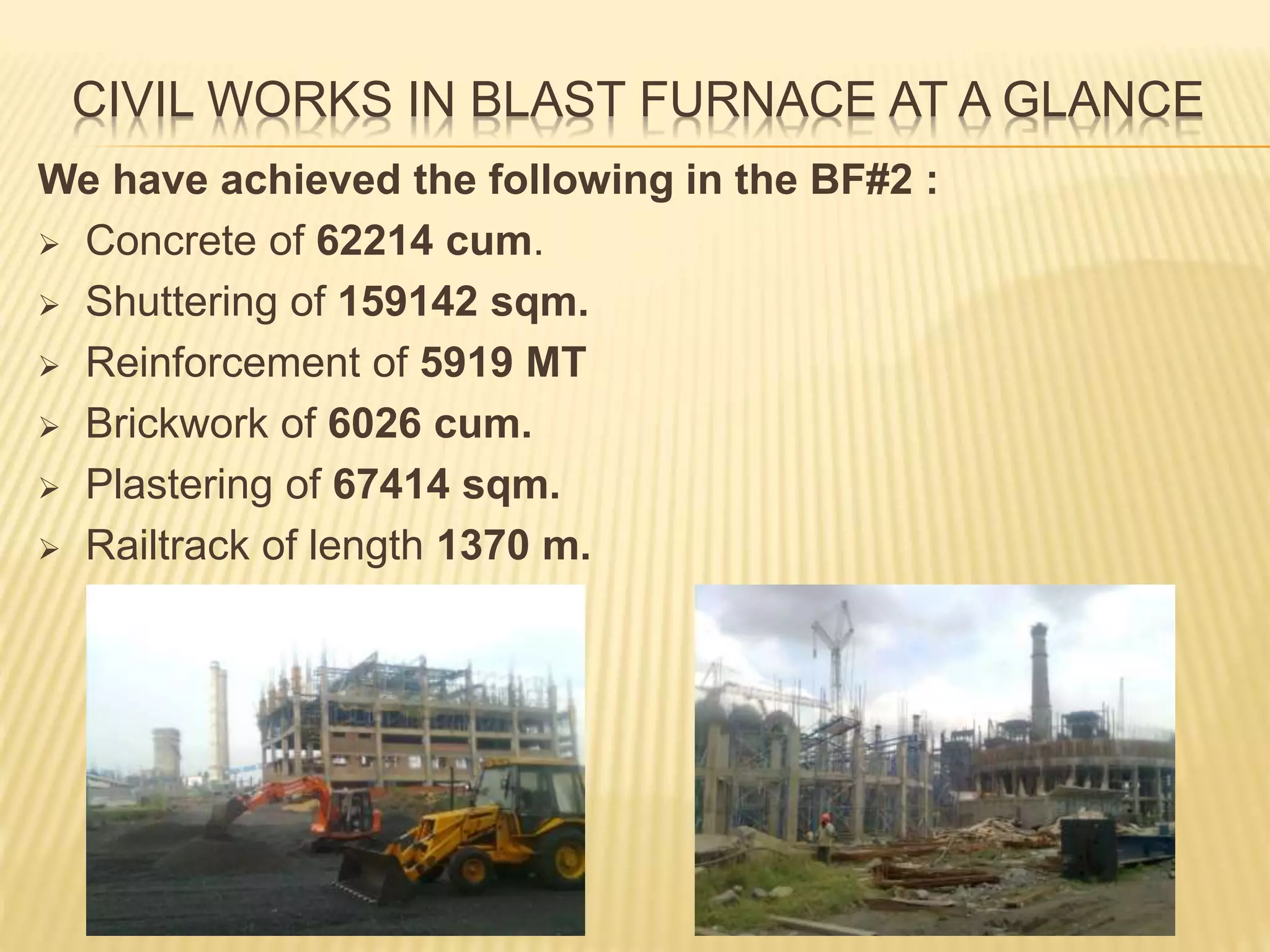

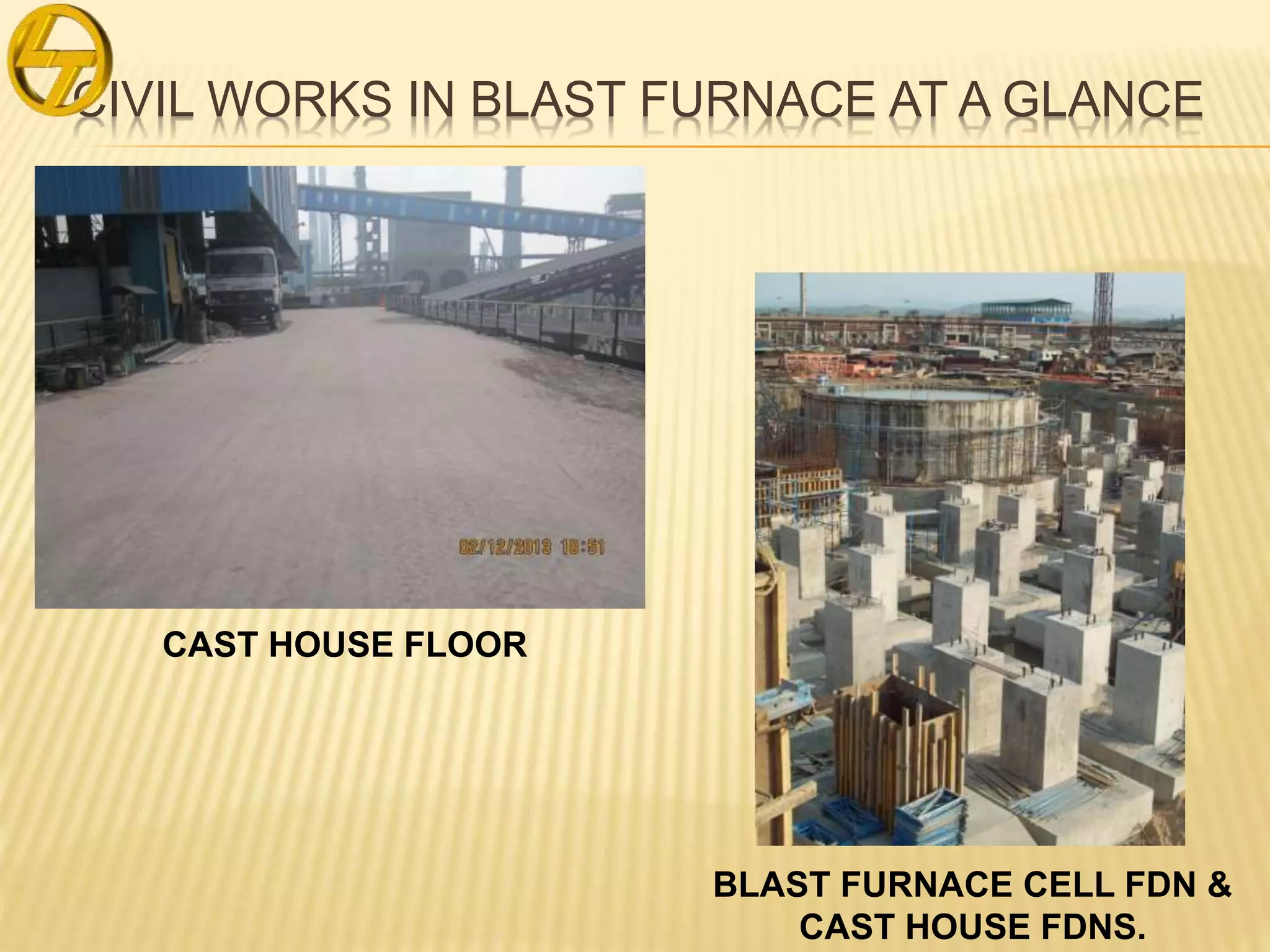

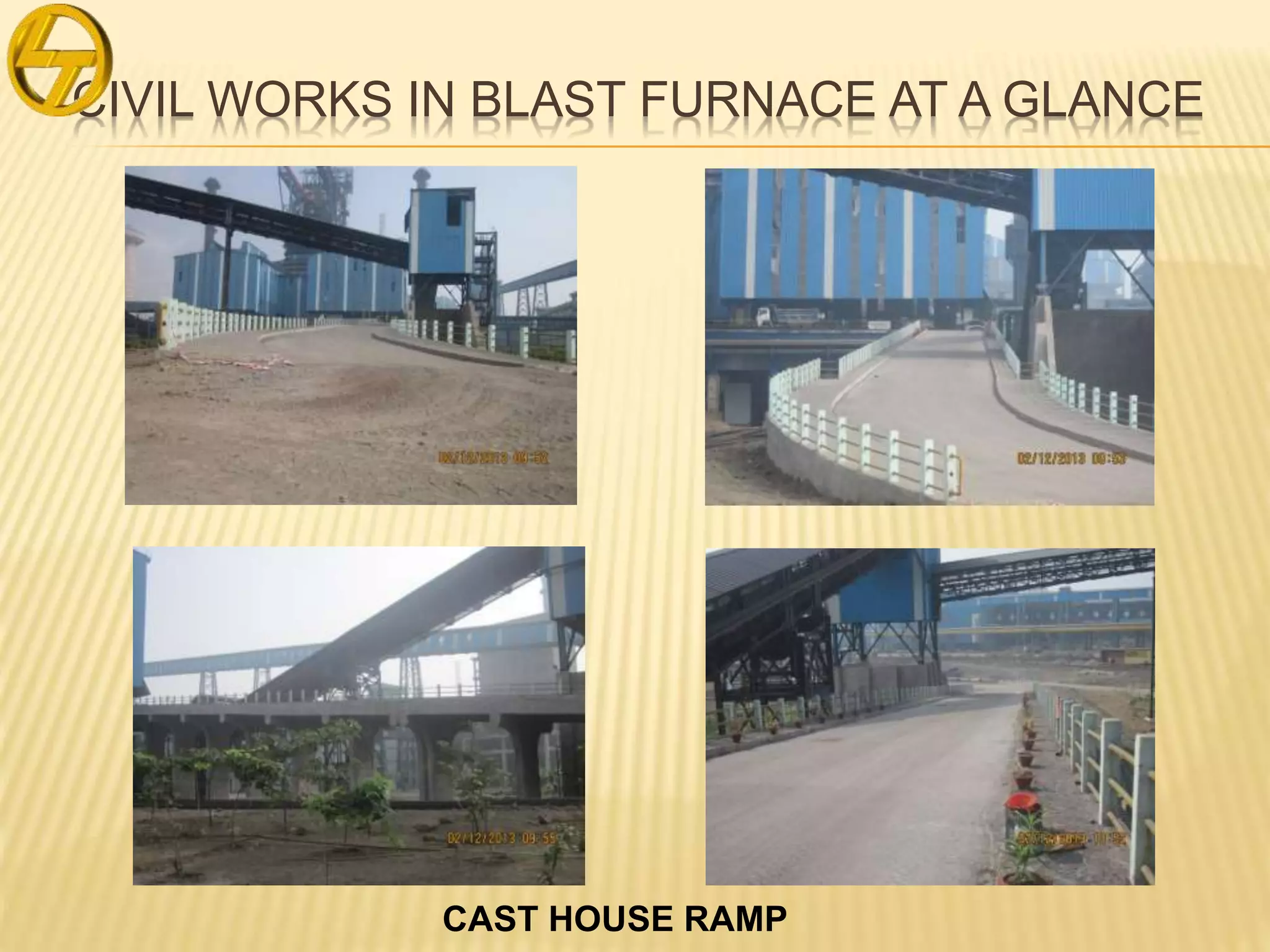

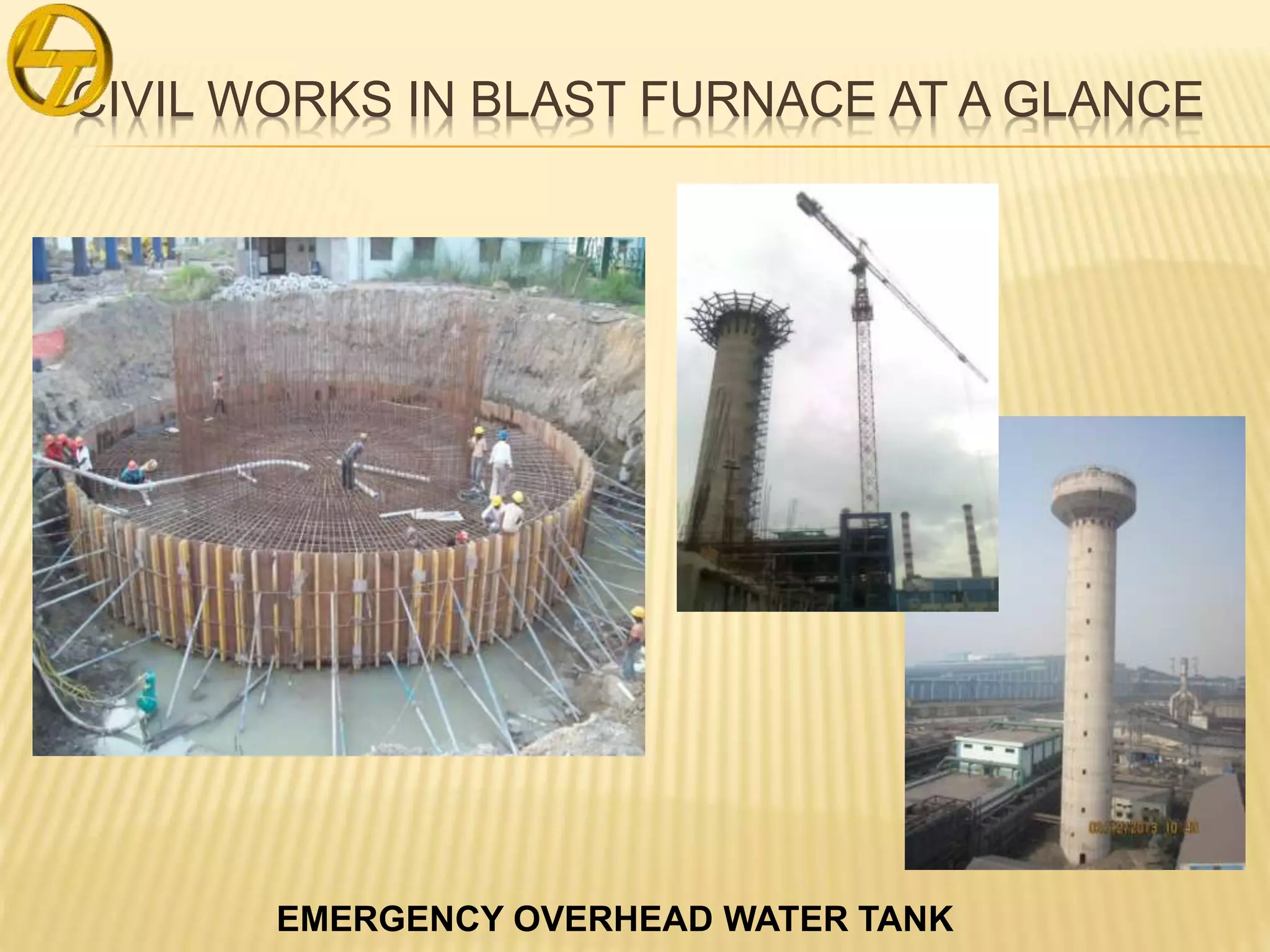

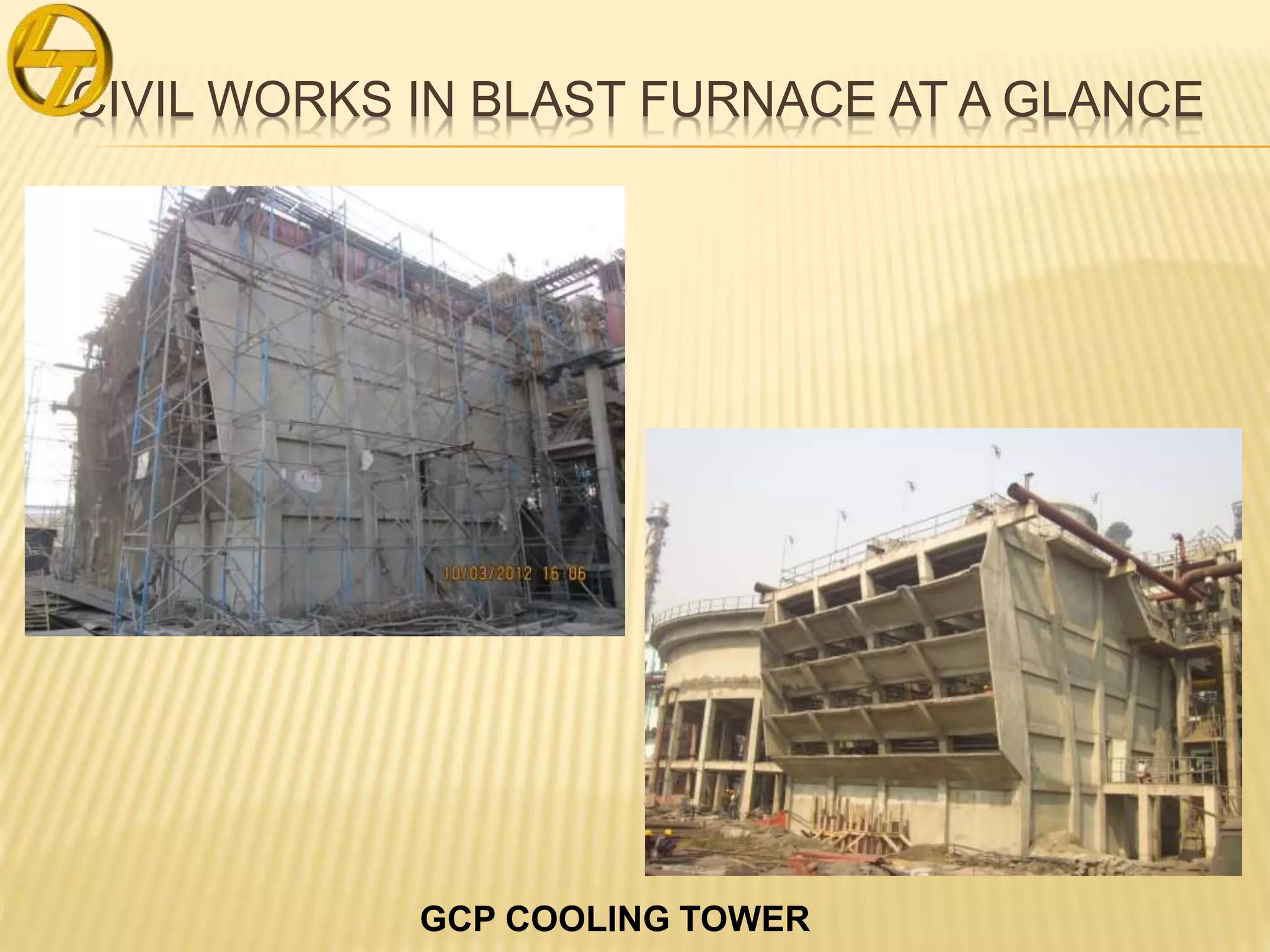

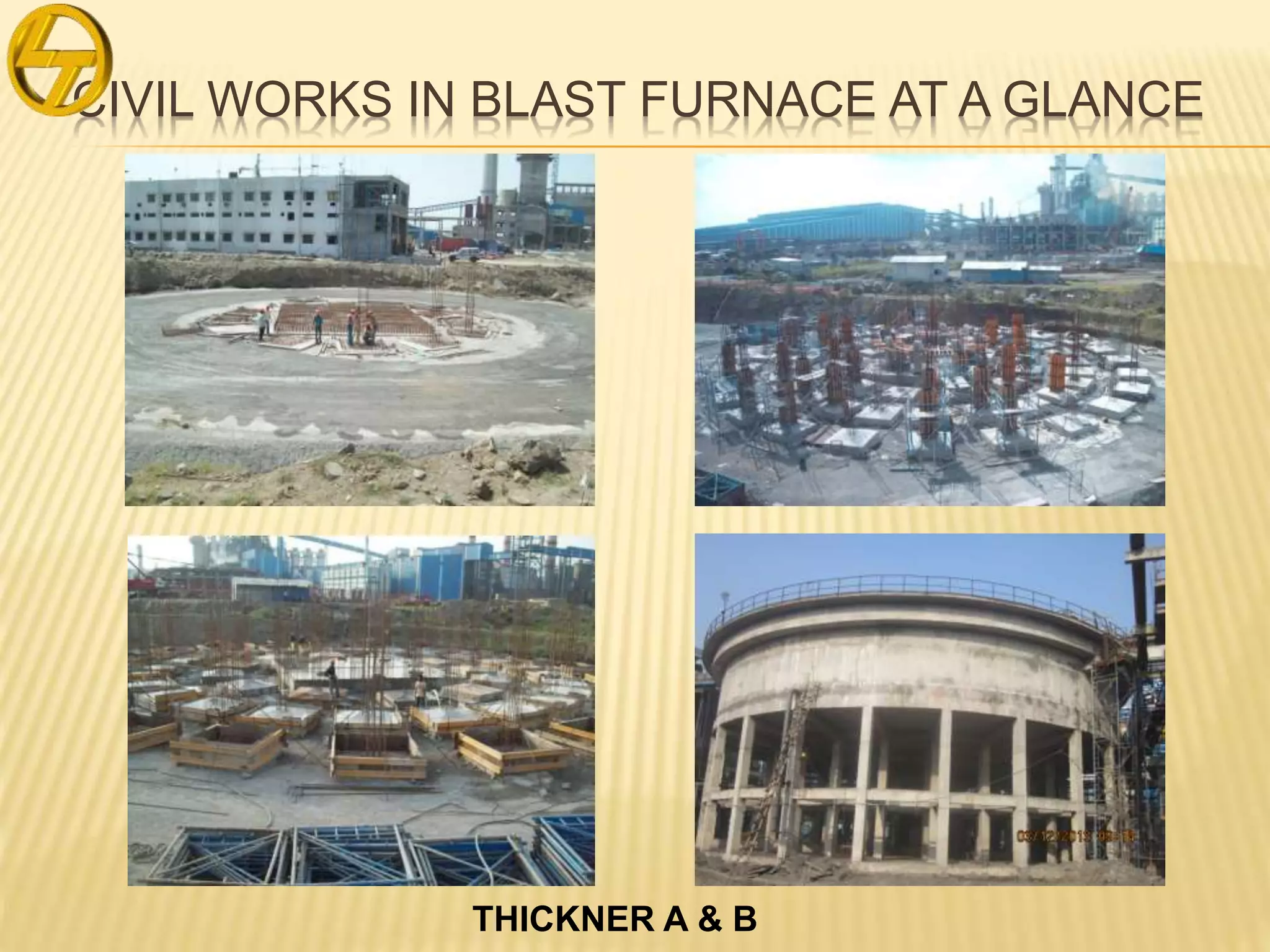

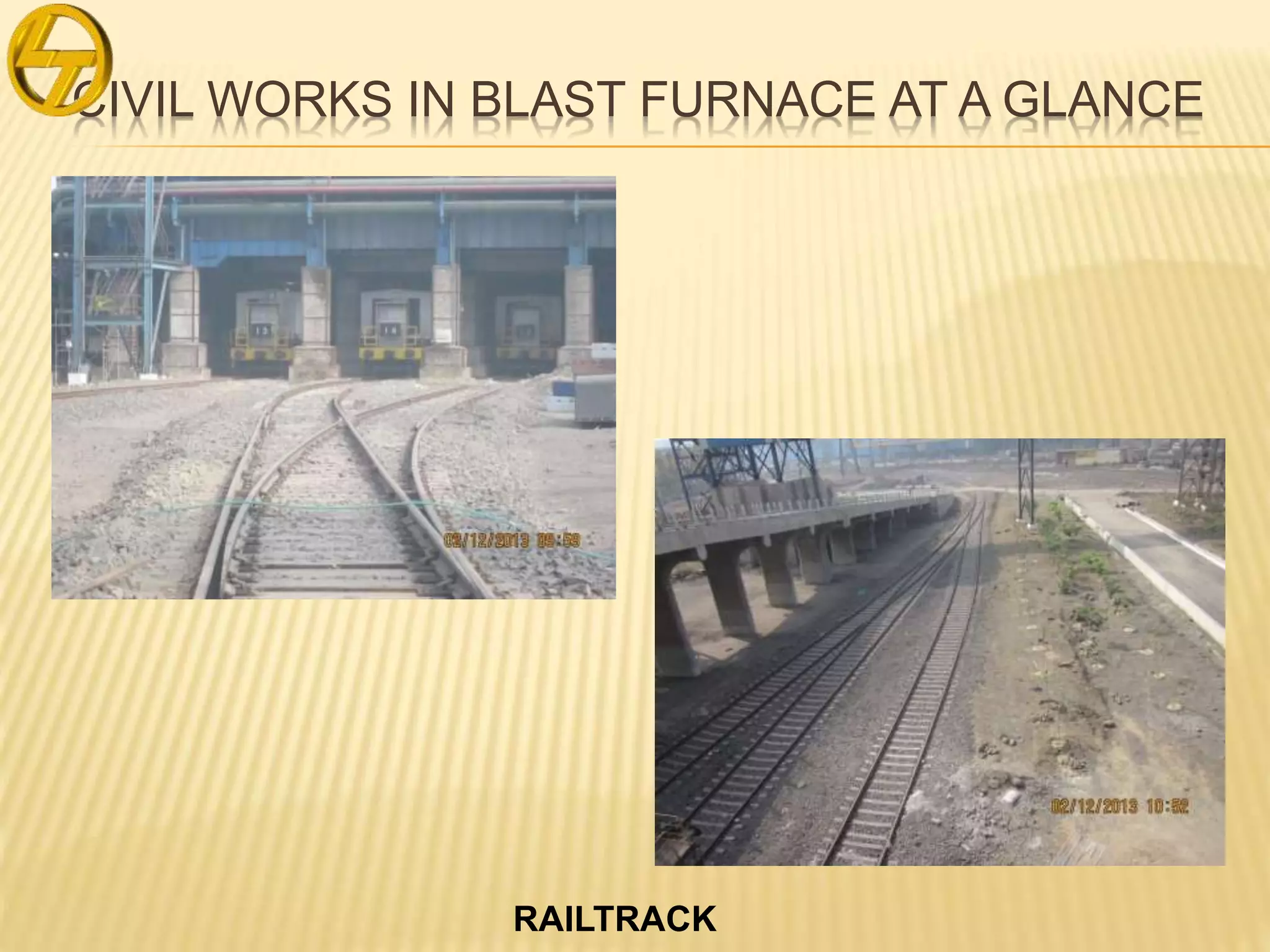

The document outlines the civil works involved in the construction of Blast Furnace #2, detailing various processes such as layout, excavation, reinforcement, and concrete mixing. It discusses different types of concrete, their mixtures, properties, and advantages, including PCC, RCC, HRC, and PSC. Additionally, it provides insights into specific construction methods and requirements for quality assurance in a large-scale industrial project.