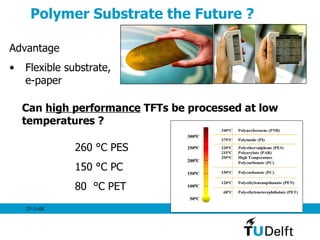

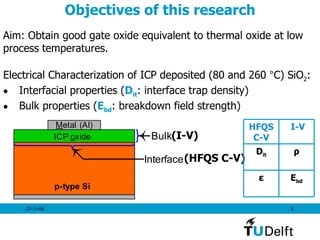

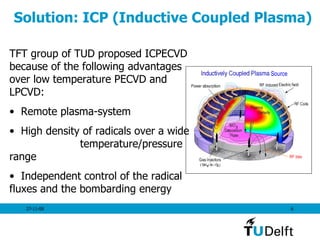

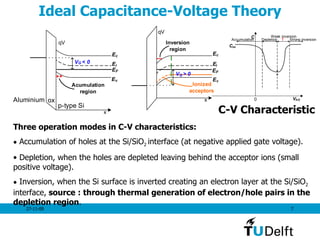

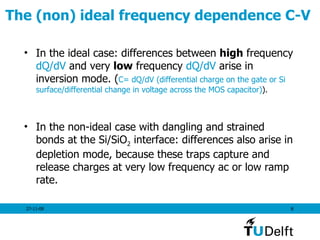

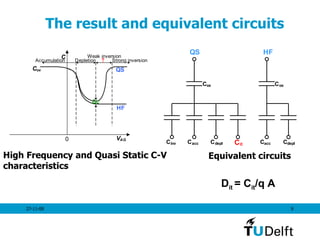

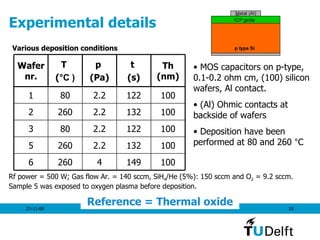

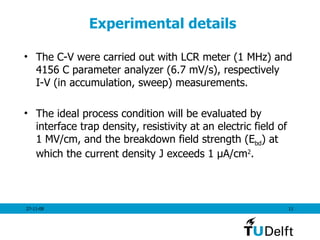

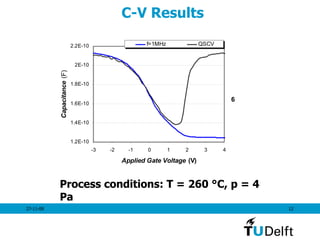

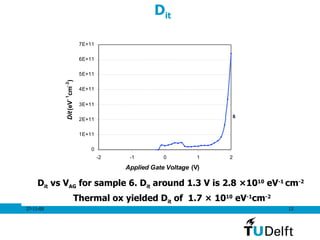

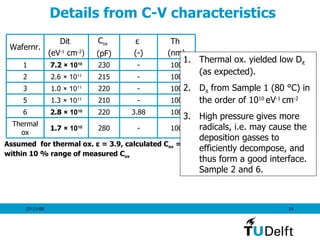

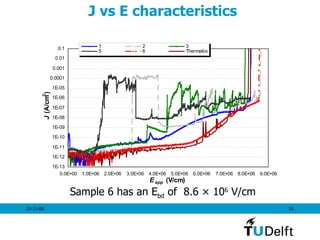

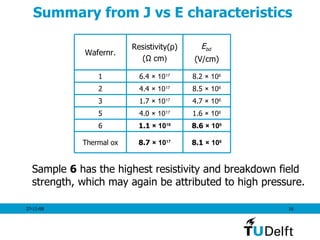

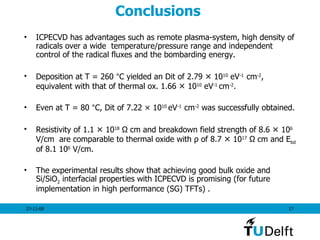

The document discusses electrical characterization of silicon dioxide films deposited by inductively coupled plasma at various temperatures. Capacitance-voltage and current-voltage measurements were performed on metal-oxide-semiconductor capacitors to analyze the interface trap density, resistivity, and breakdown field strength of the deposited films. The best results were obtained for a film deposited at 260°C, which had an interface trap density comparable to thermal oxide and a high resistivity and breakdown field strength. Even at a deposition temperature of 80°C, reasonably good electrical characteristics were achieved, demonstrating the potential of this method for low-temperature fabrication of high-performance thin-film transistors.