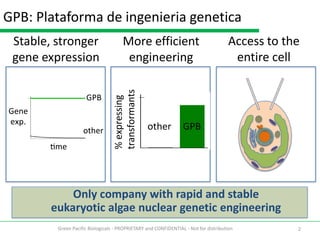

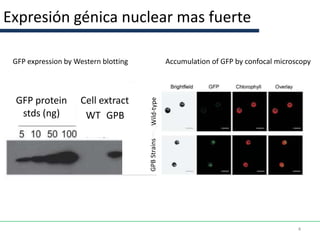

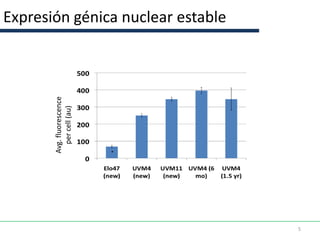

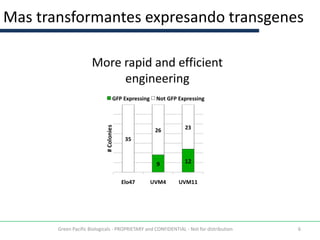

1) Green Pacific Biologicals has developed a genetic engineering platform that enables more stable and efficient nuclear gene expression in eukaryotic algae.

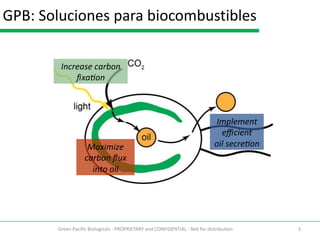

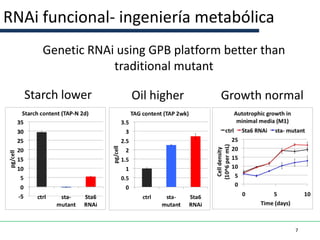

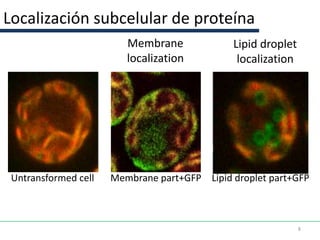

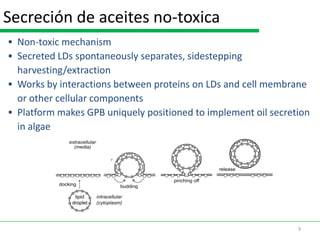

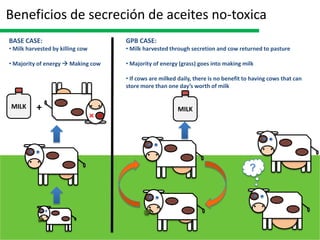

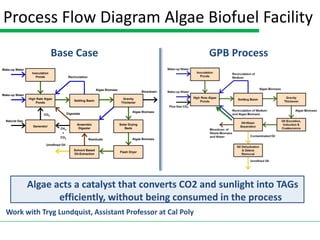

2) The platform allows for rapid genetic engineering of algae to increase carbon fixation and oil production through techniques such as increasing carbon flux into oil and implementing efficient oil secretion.

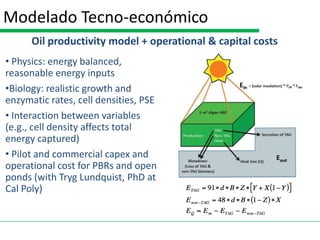

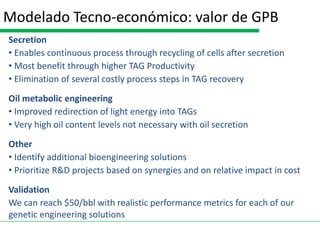

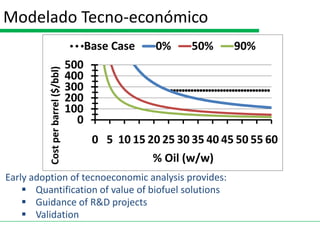

3) Modeling by Green Pacific Biologicals and a professor at Cal Poly suggests their oil secretion approach could lower the cost of algal biofuels production to $50 per barrel, compared to over $400 per barrel for conventional approaches.