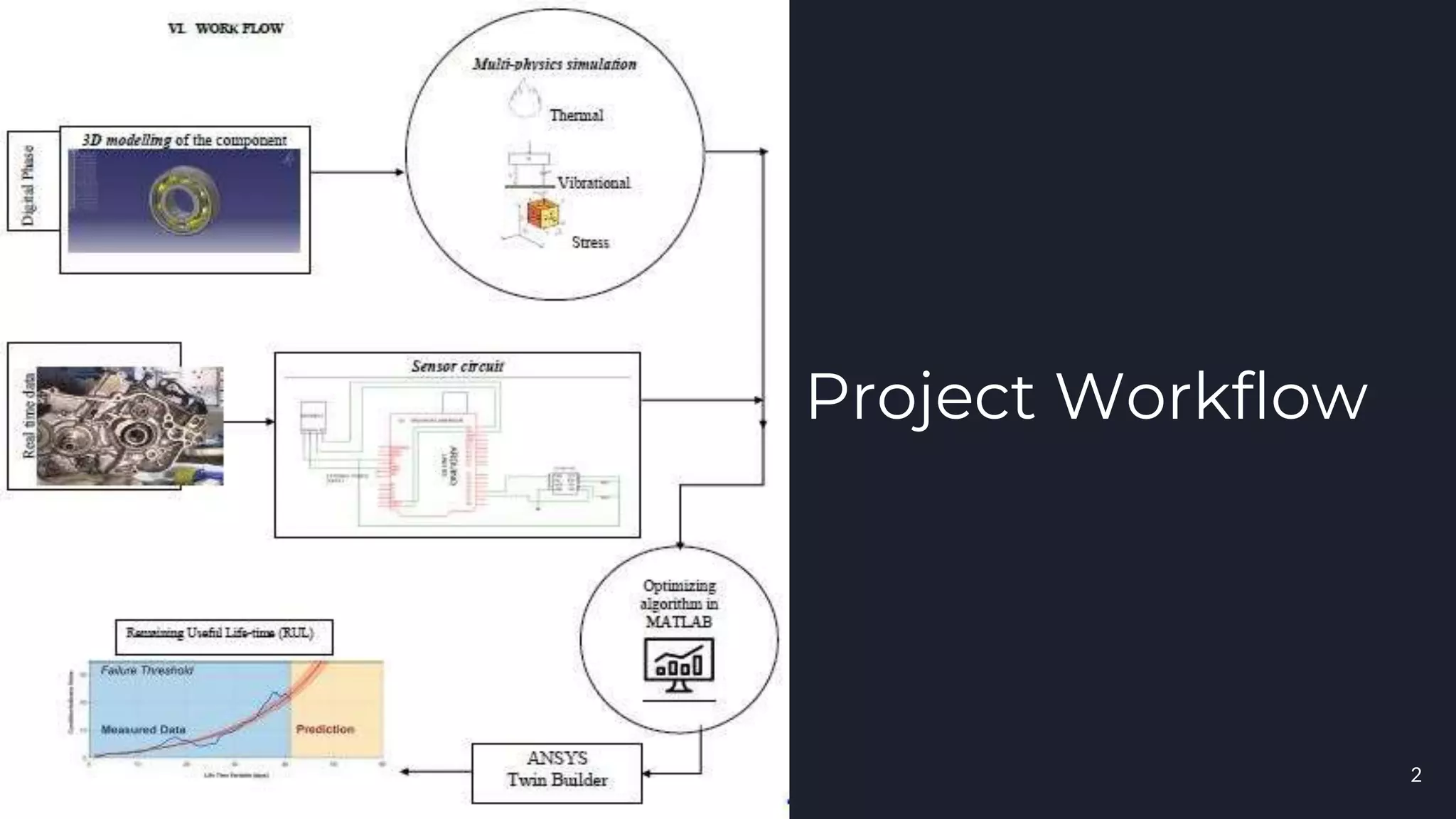

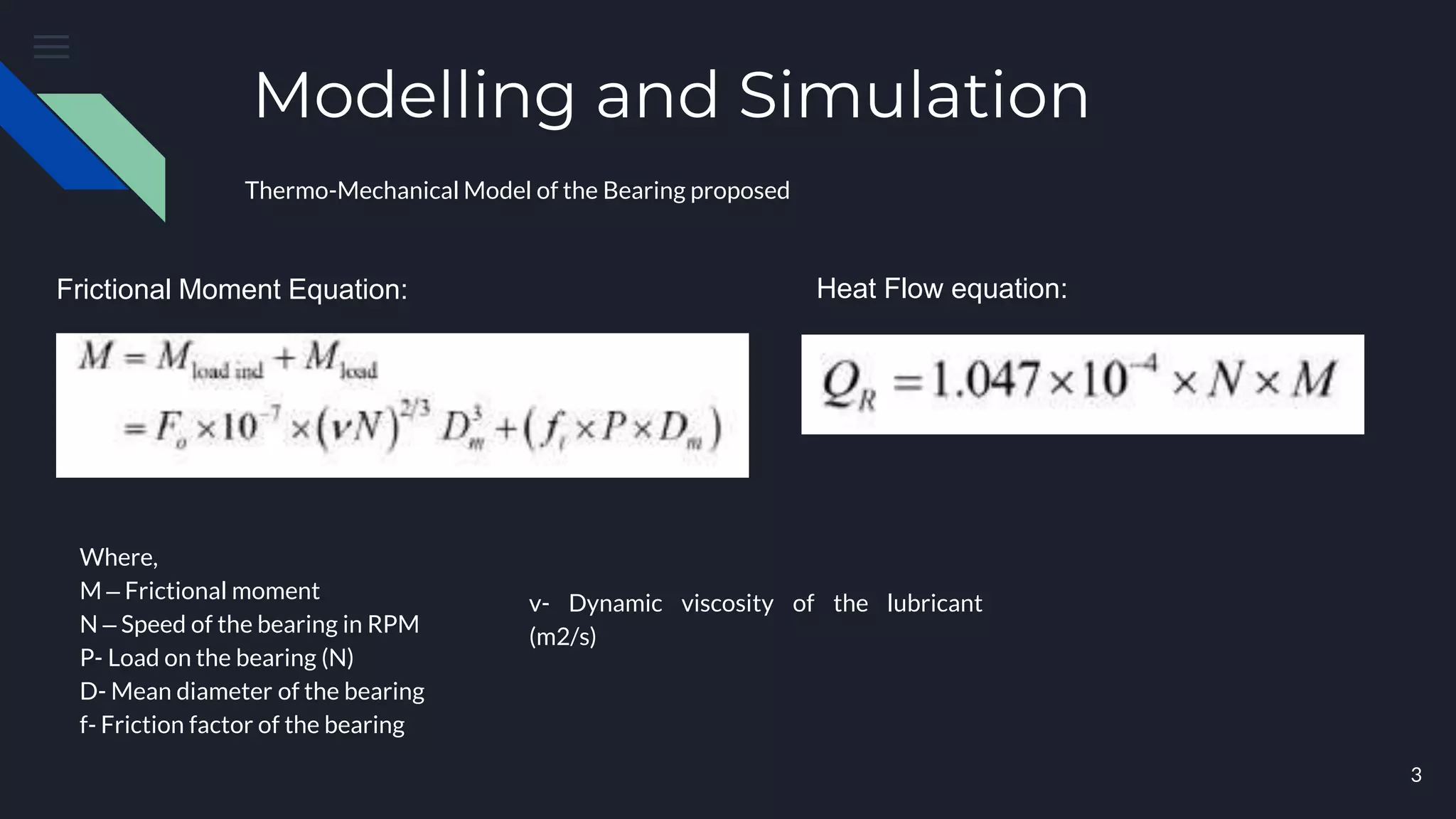

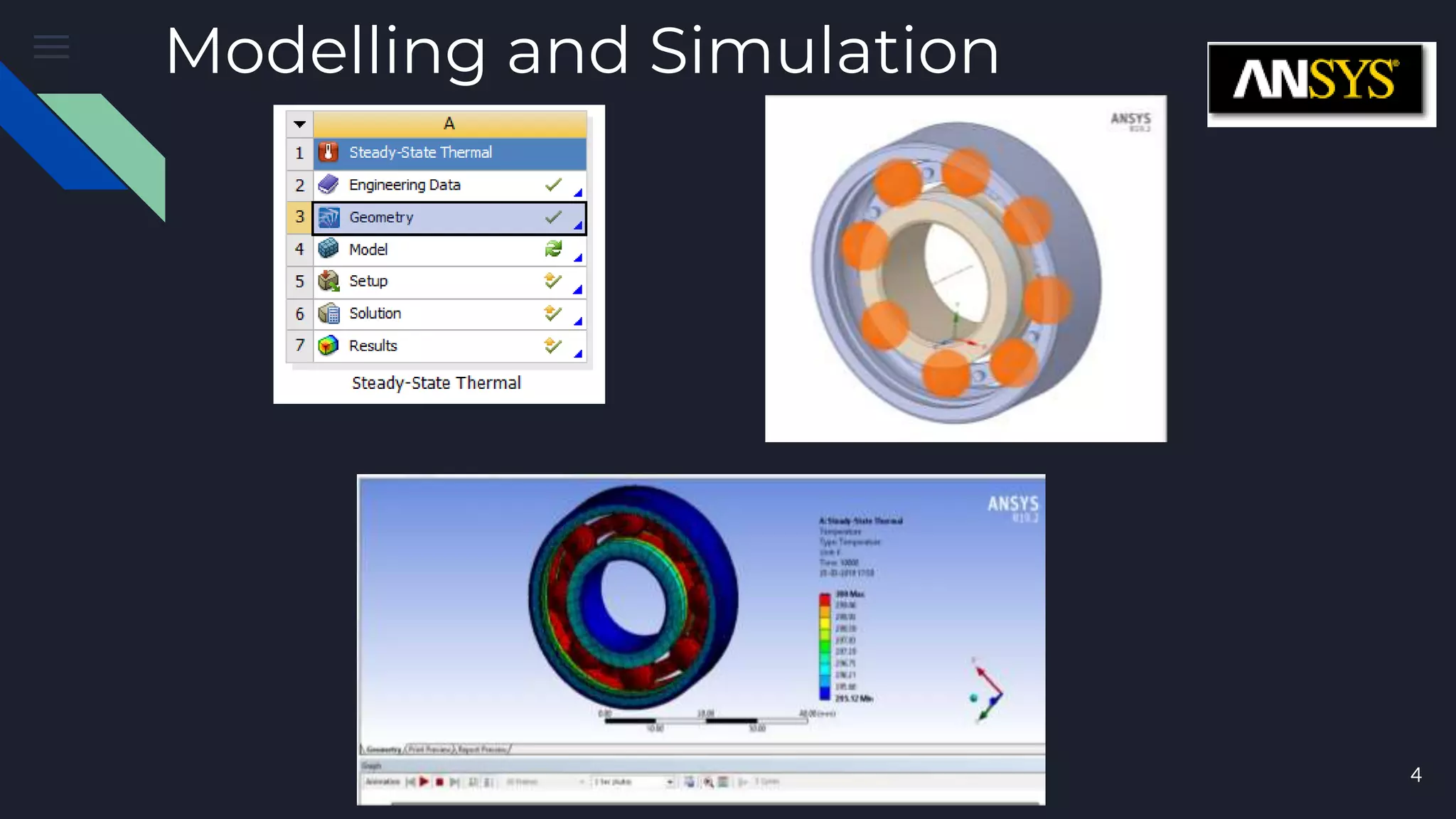

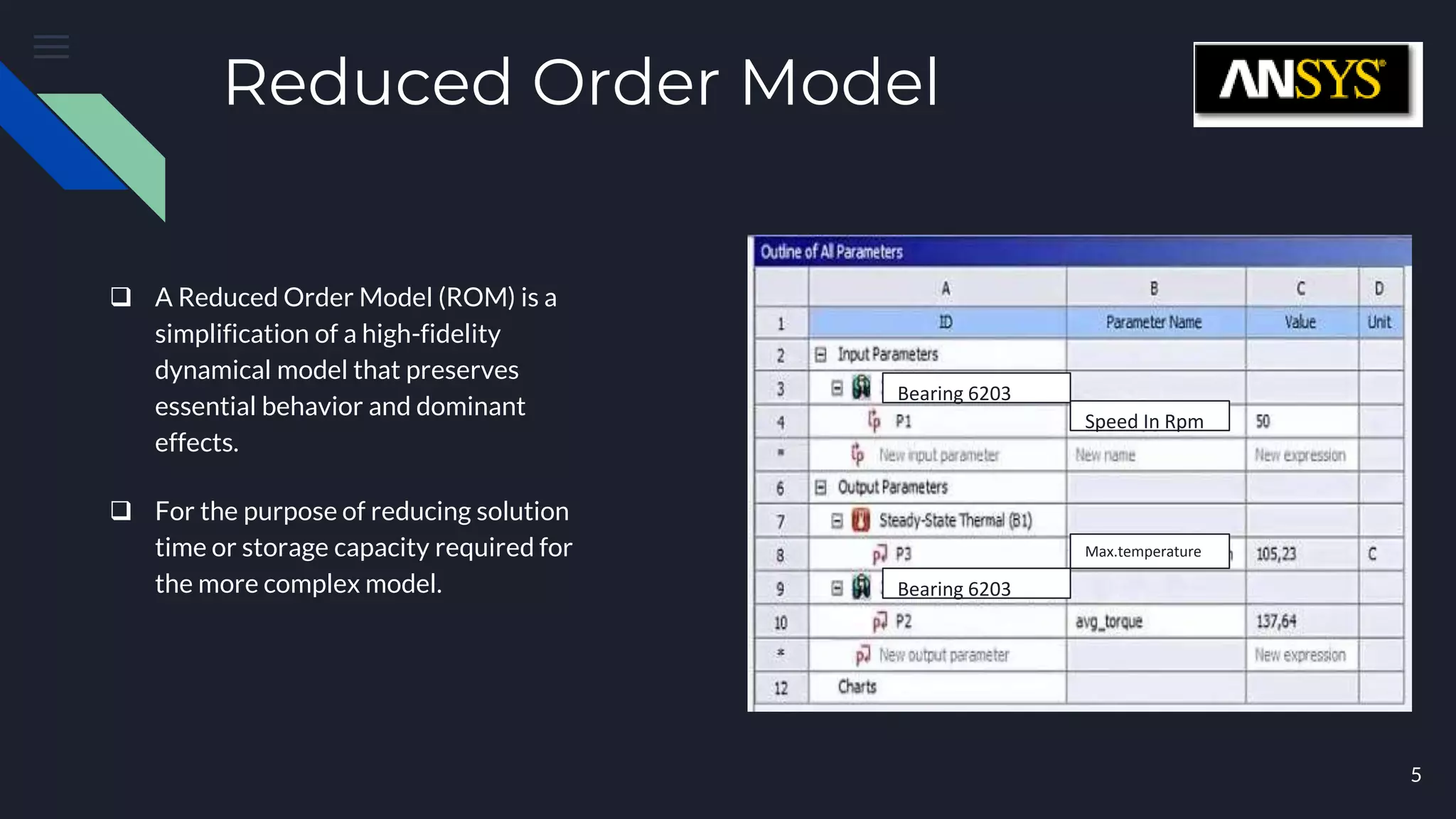

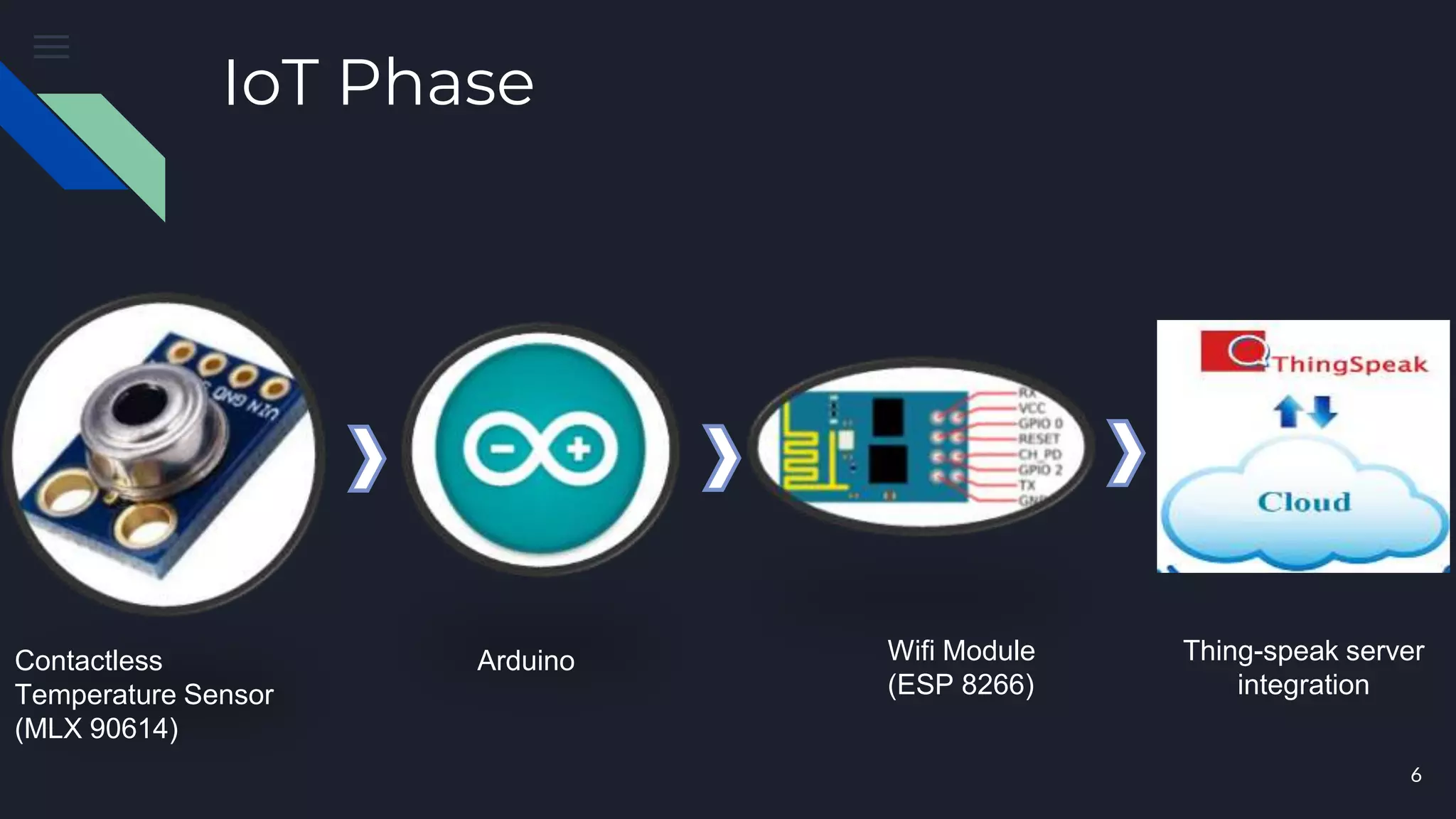

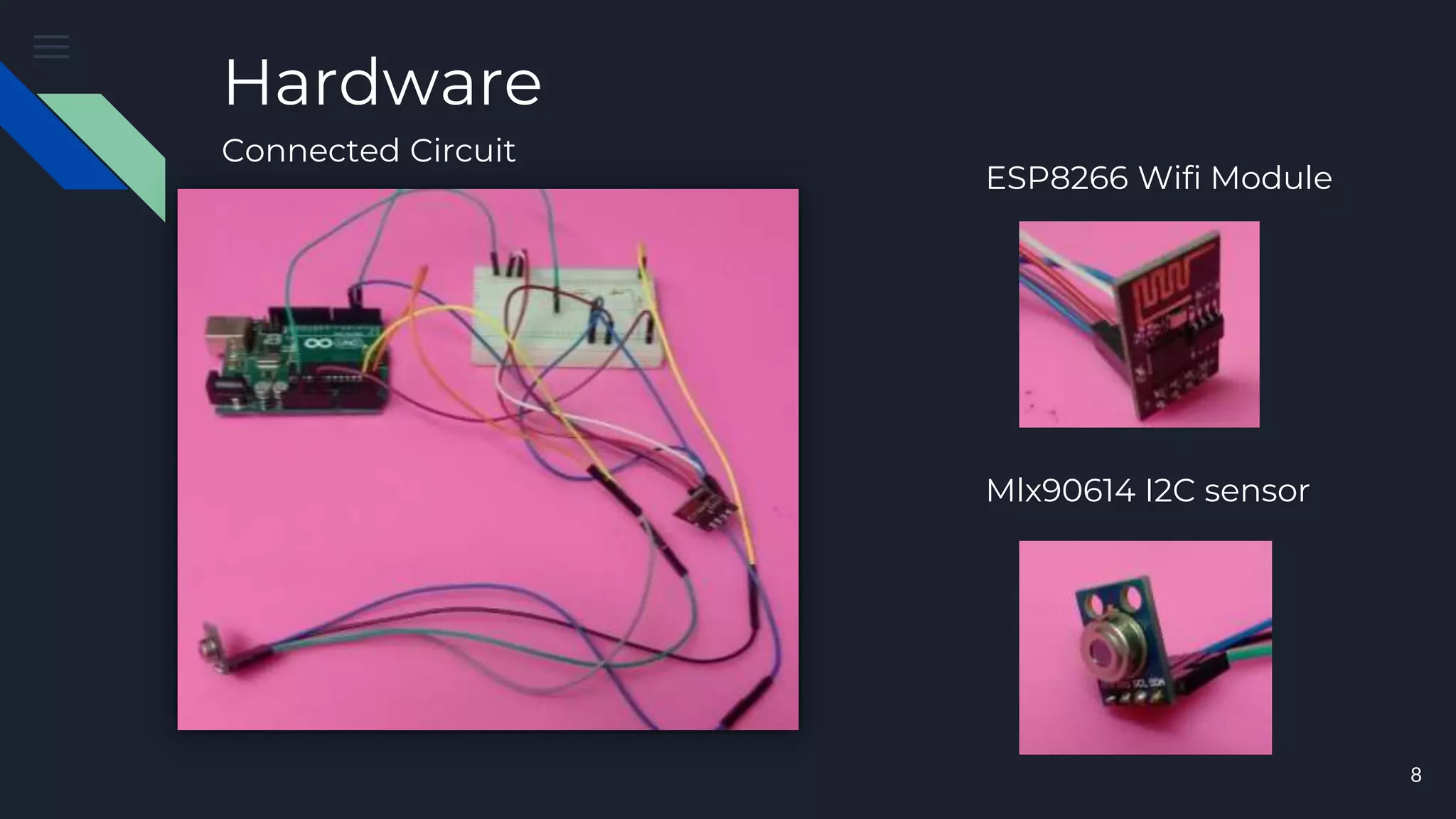

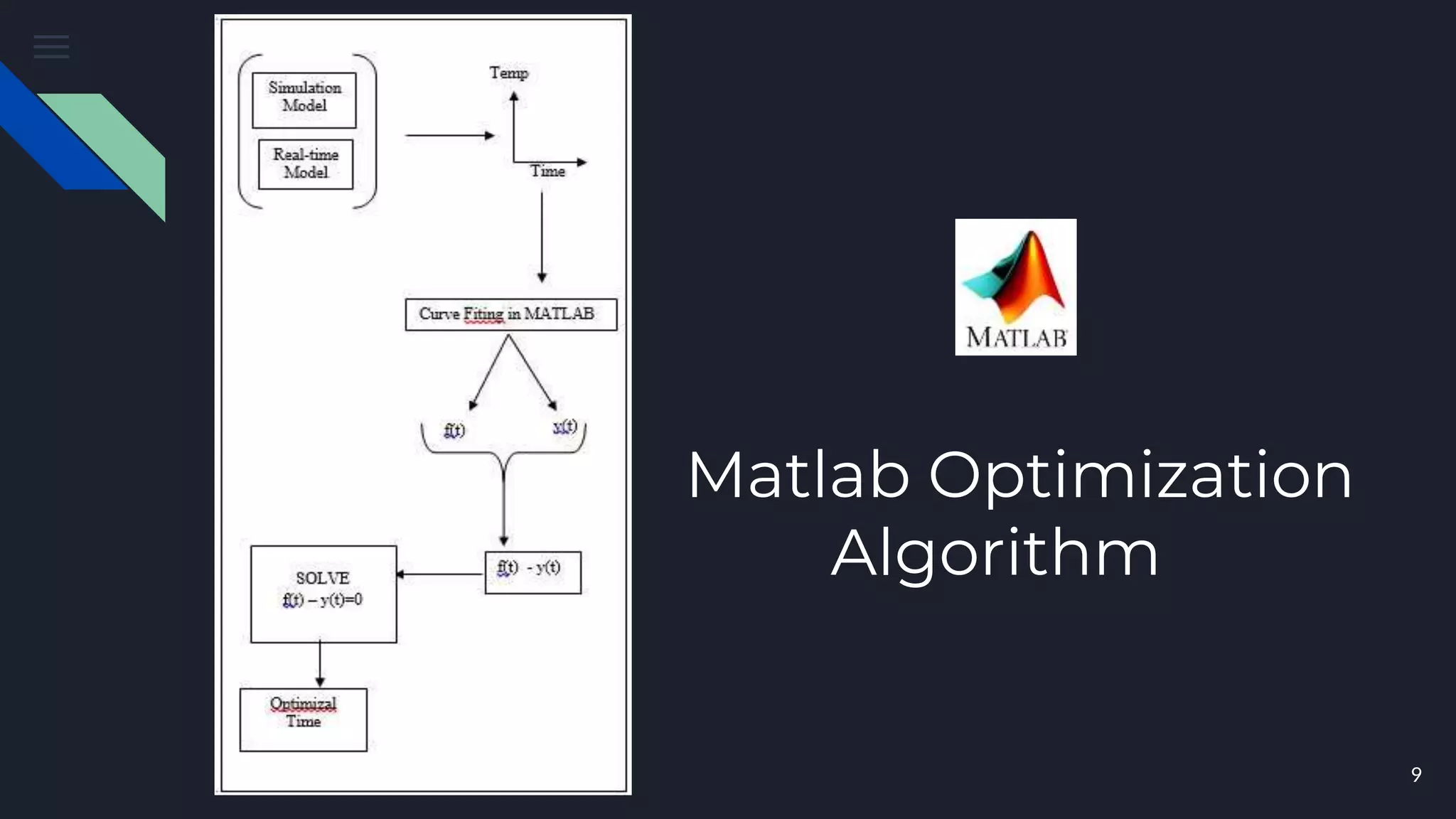

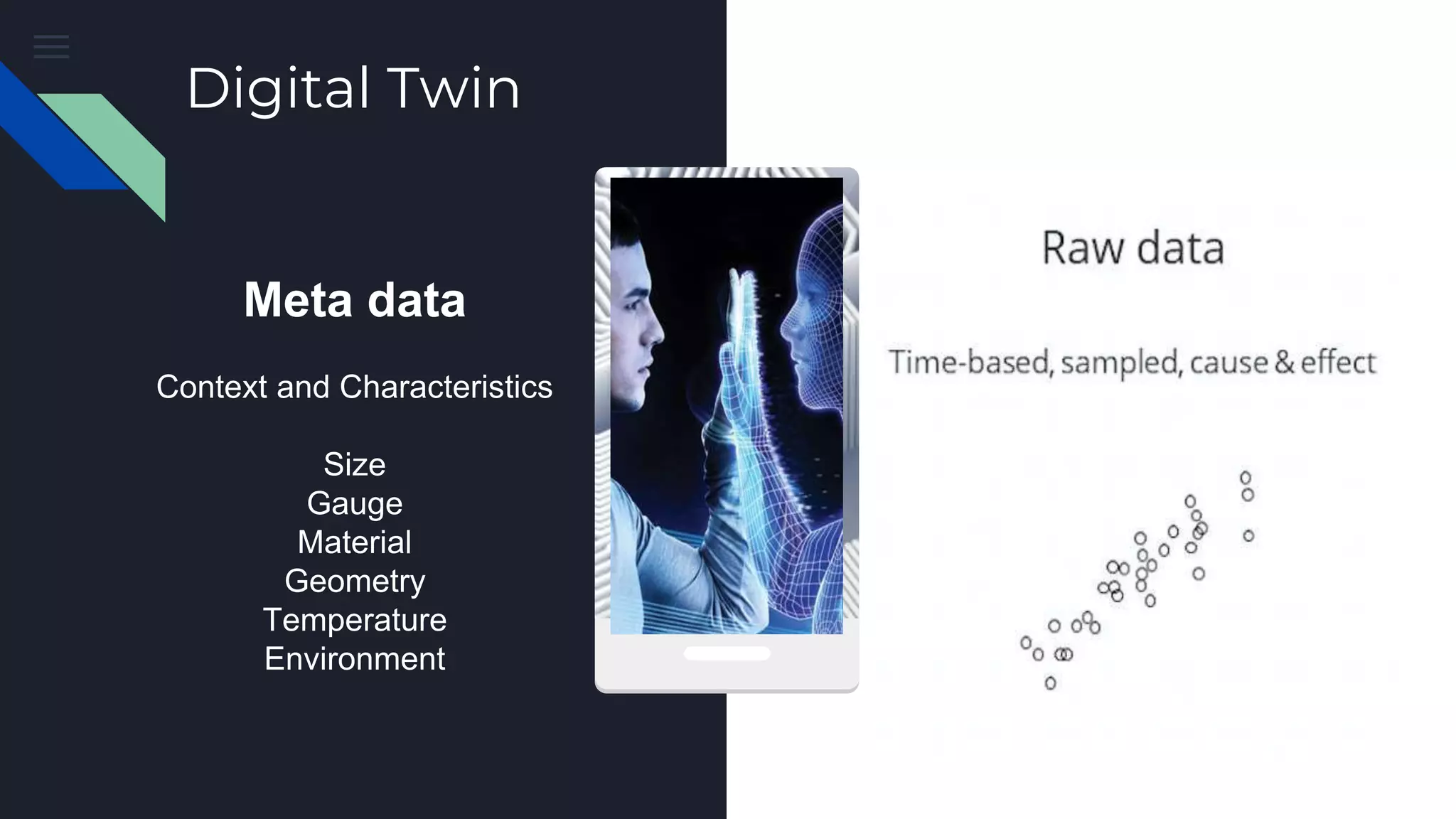

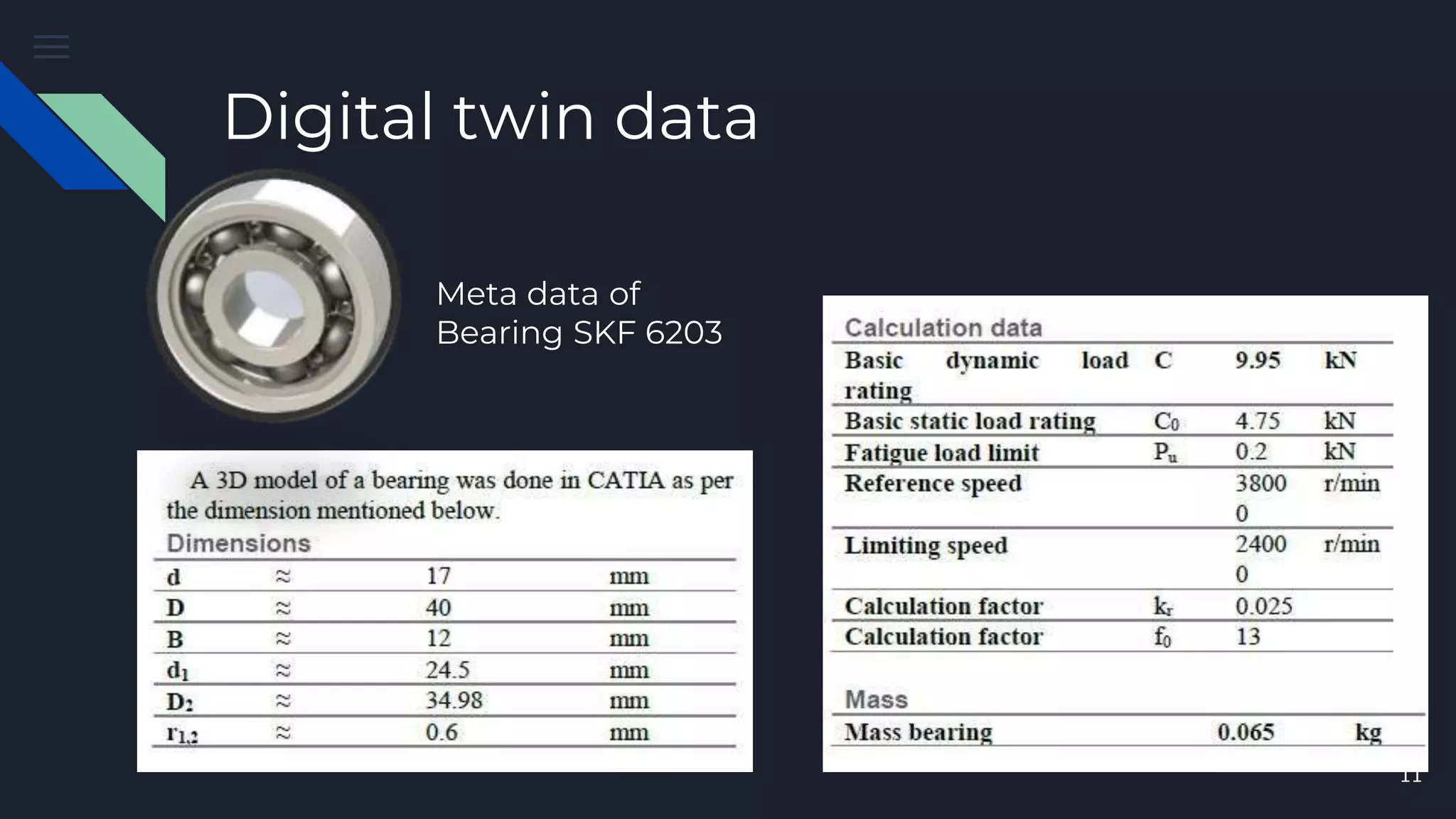

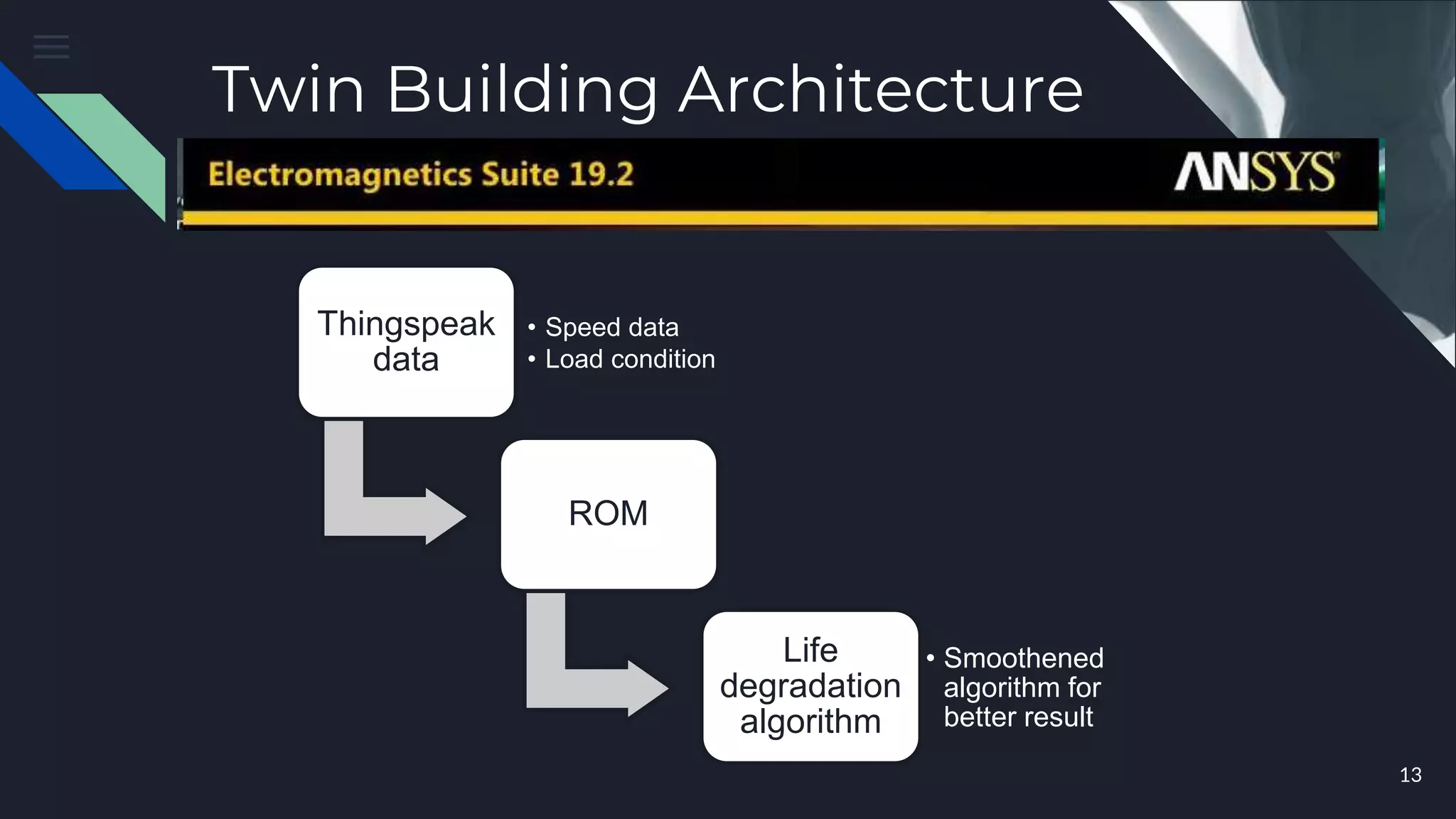

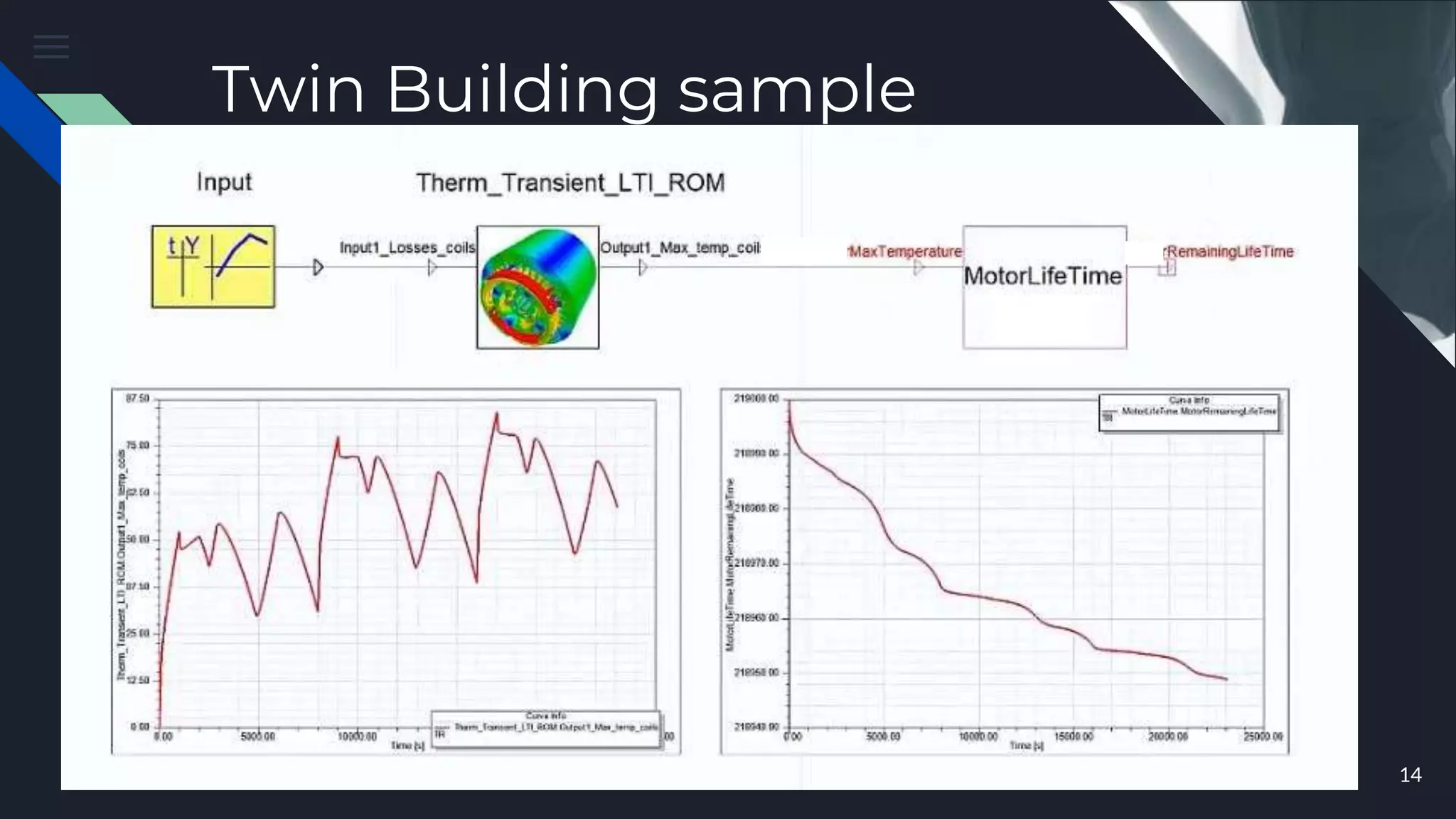

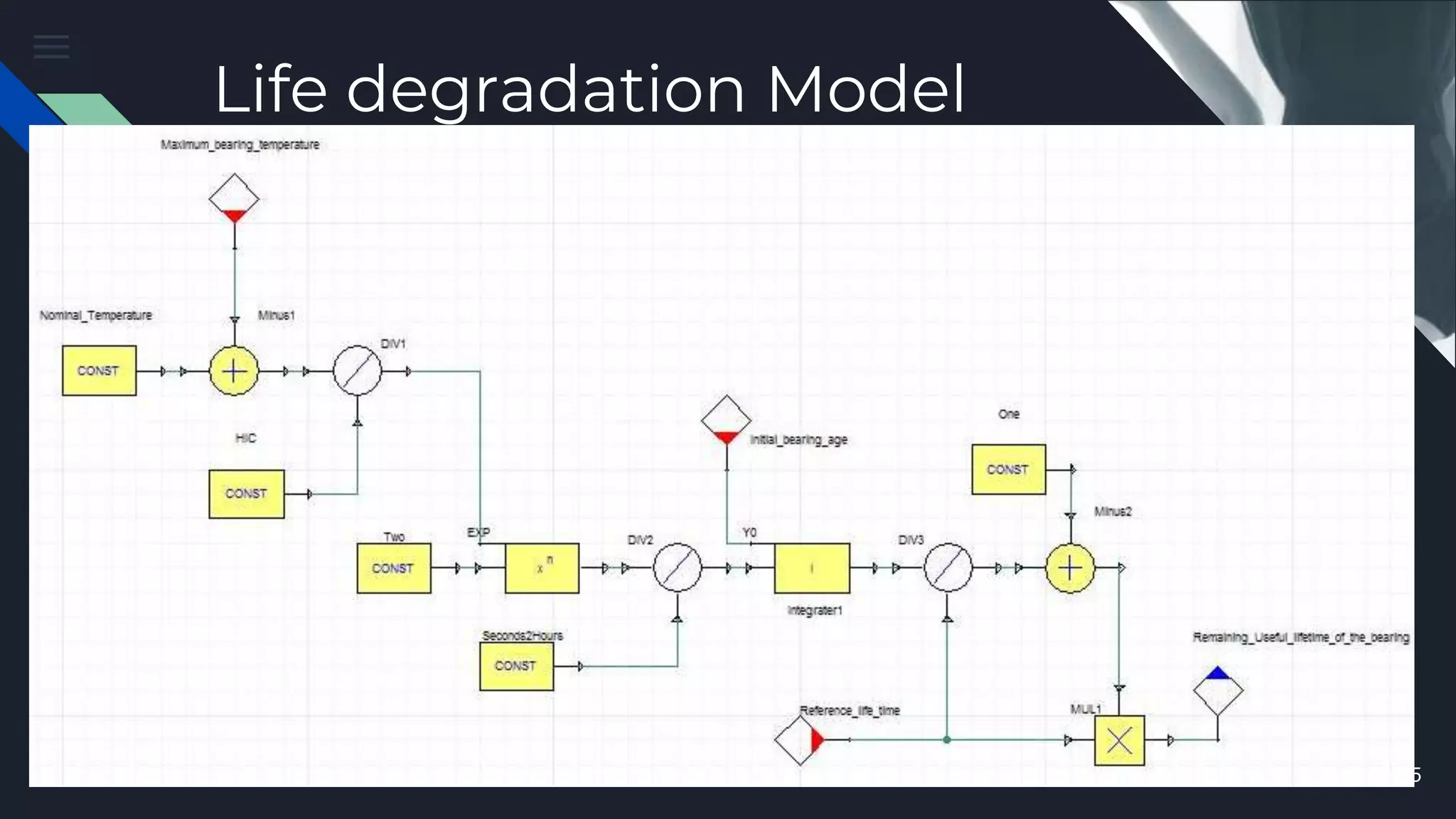

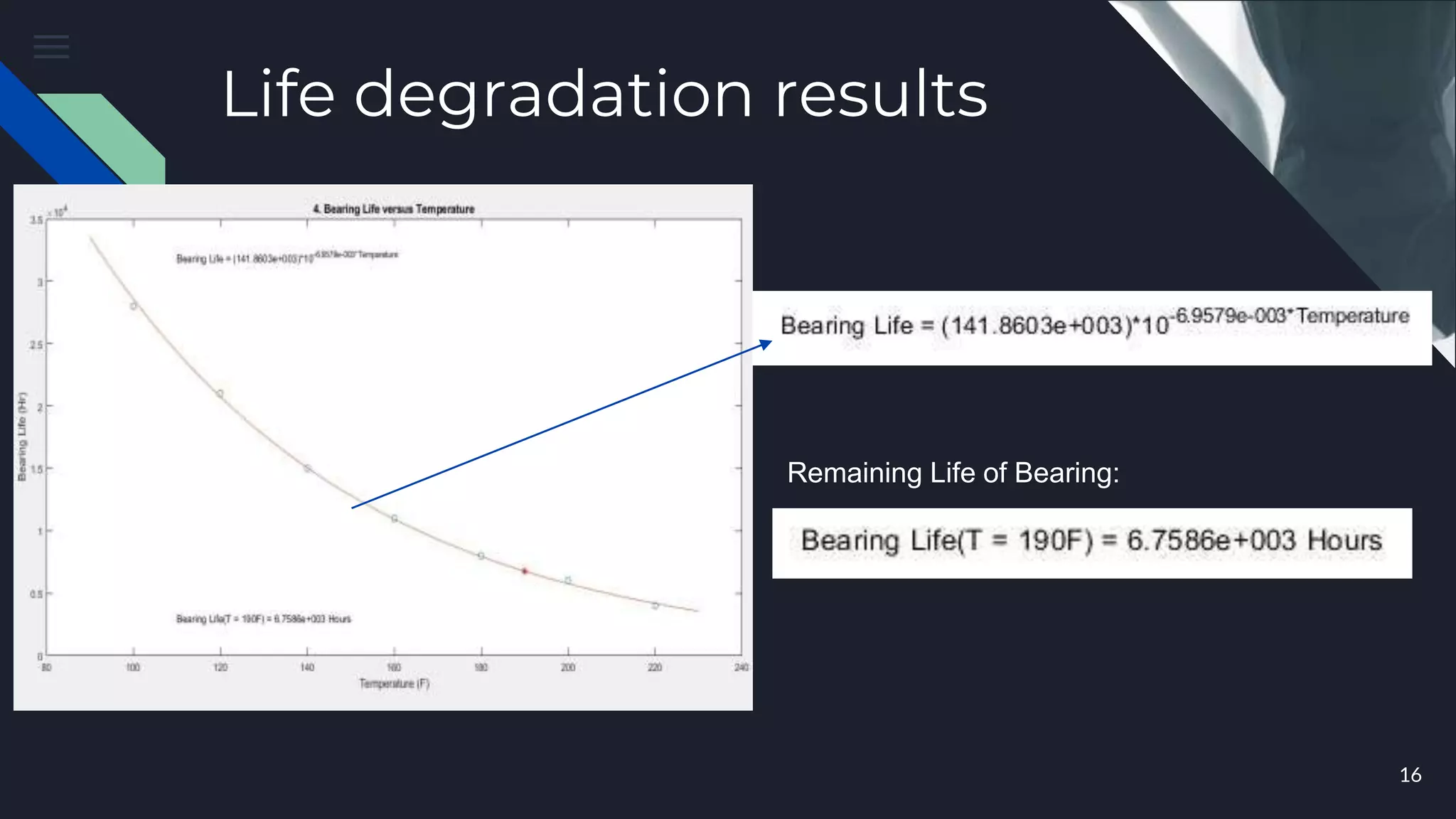

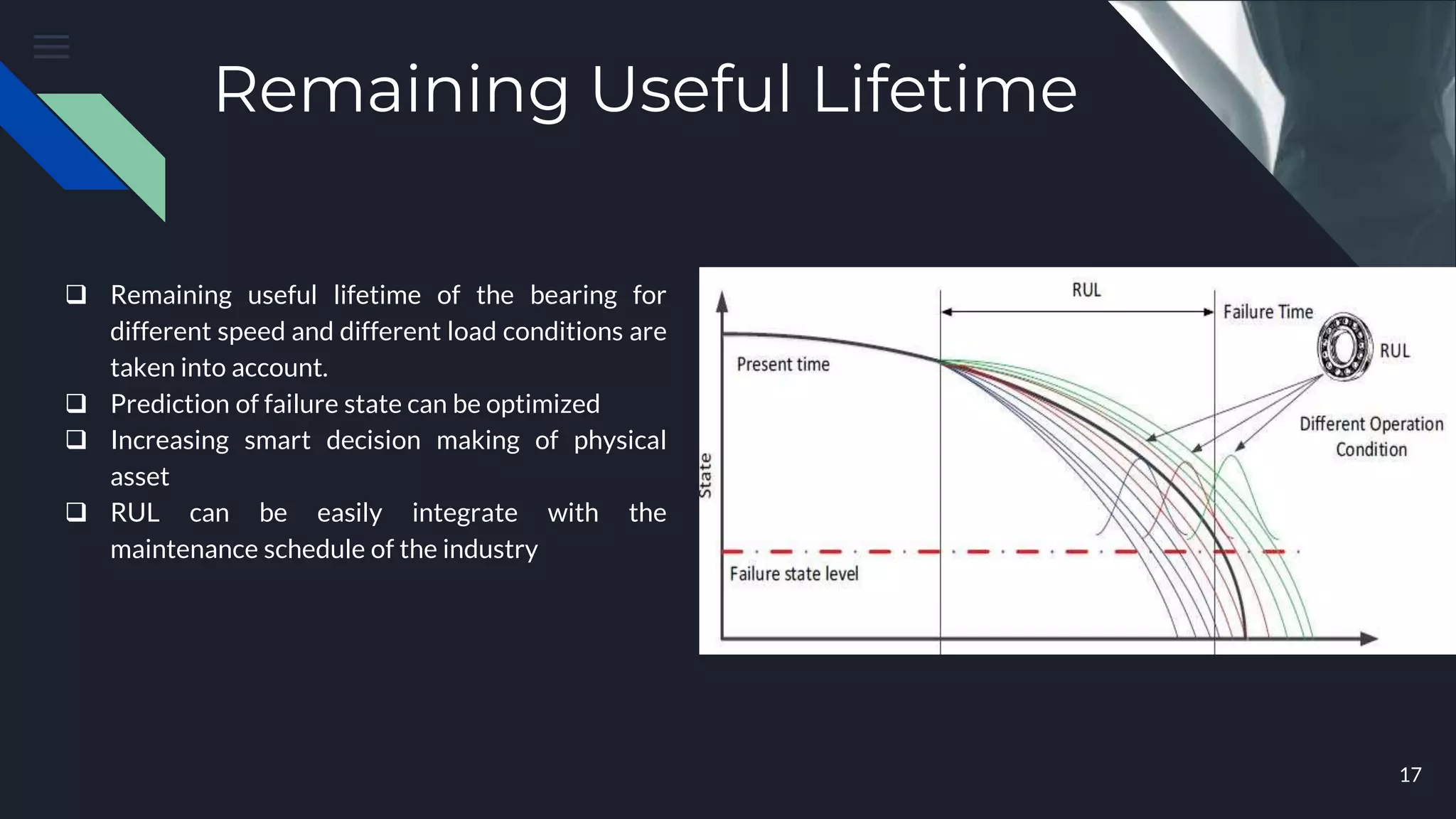

The document outlines a project on predictive maintenance of bearings using digital twin technology, focusing on modeling and simulation strategies, particularly with a reduced-order model for efficiency. It discusses the integration of IoT components such as temperature sensors and Wi-Fi modules to monitor bearing conditions, alongside methodologies for predicting remaining useful lifetime (RUL) under varying operational conditions. The ultimate goal is to optimize failure predictions and enhance decision-making for industrial maintenance scheduling.