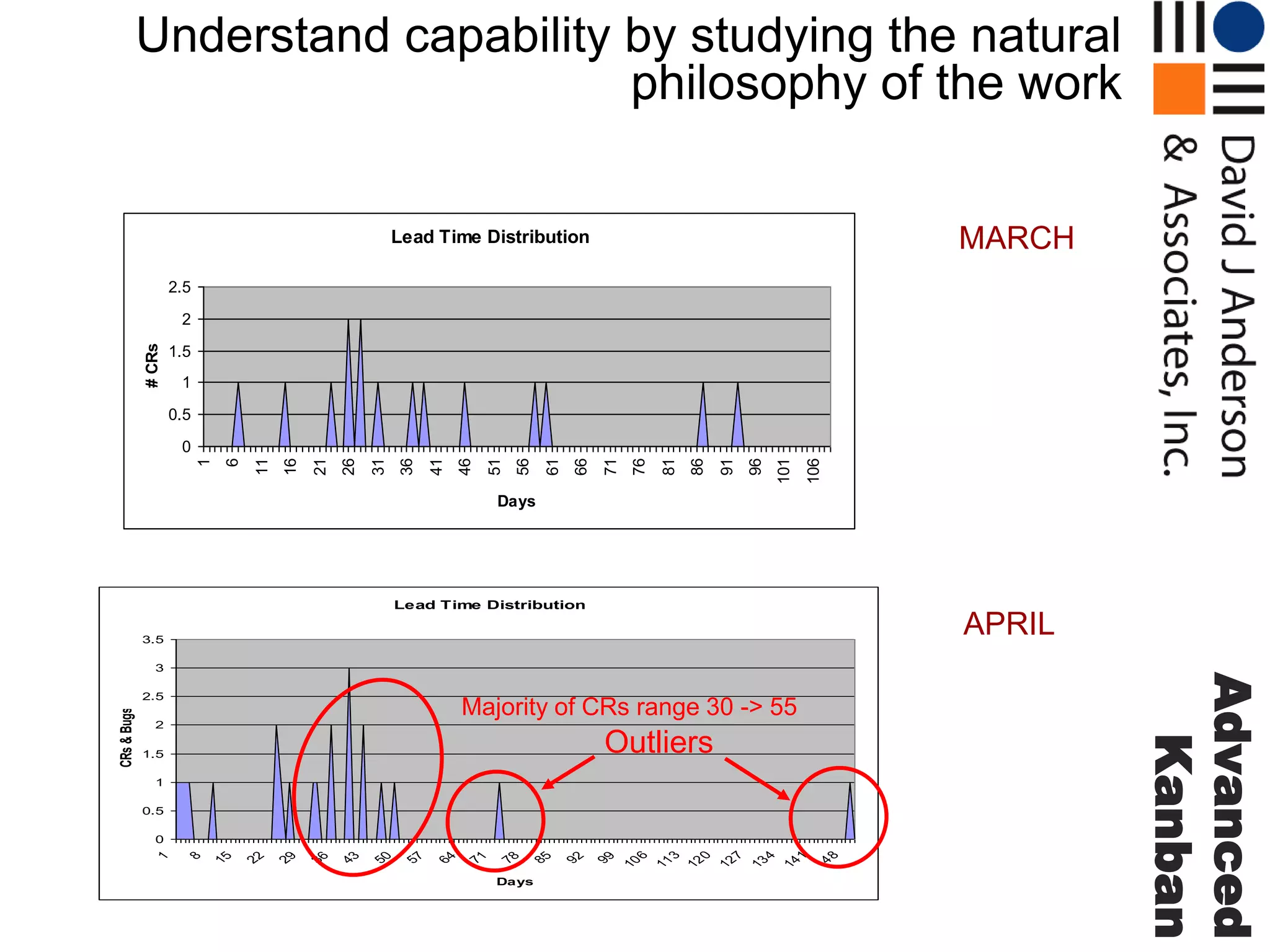

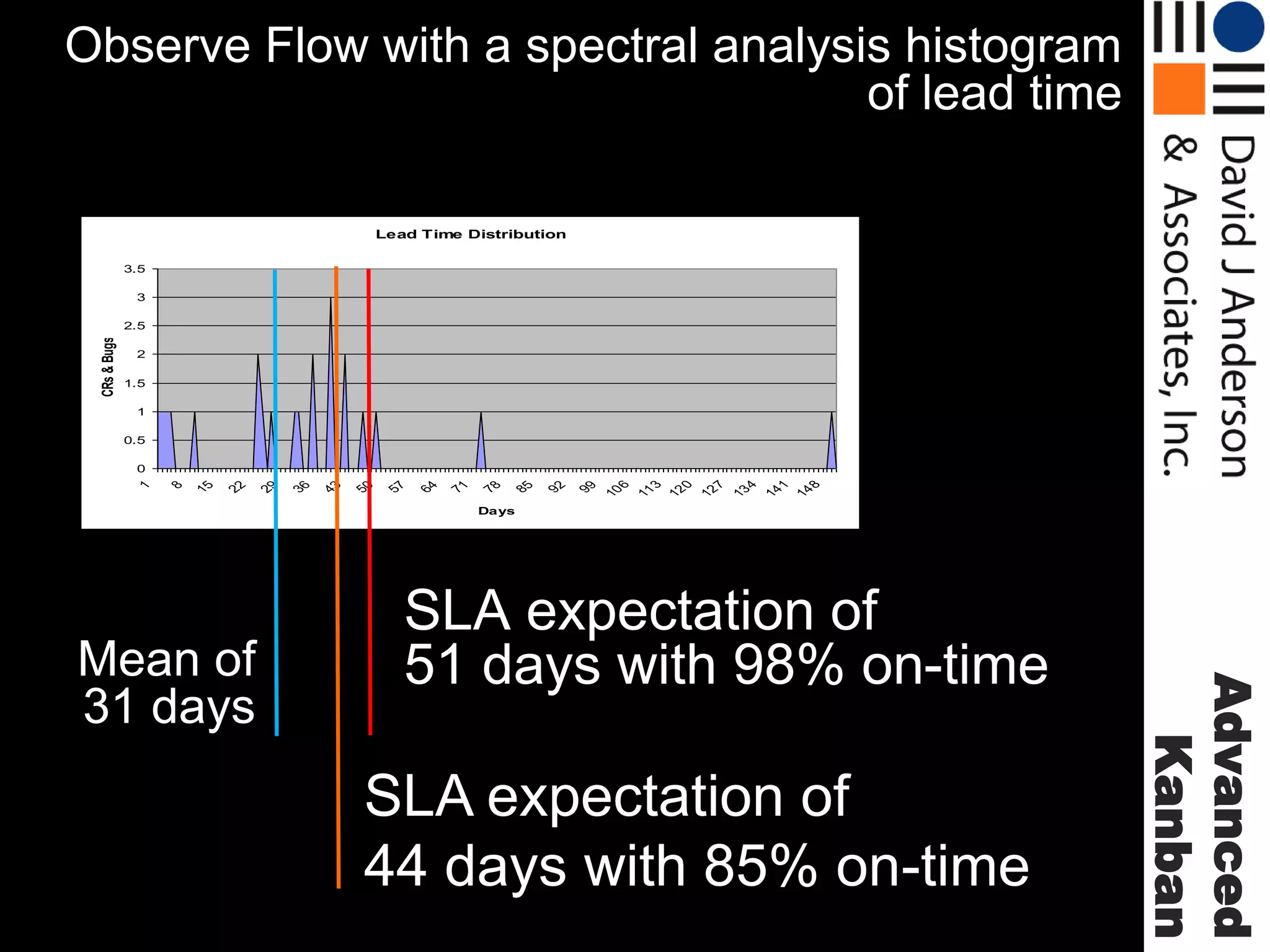

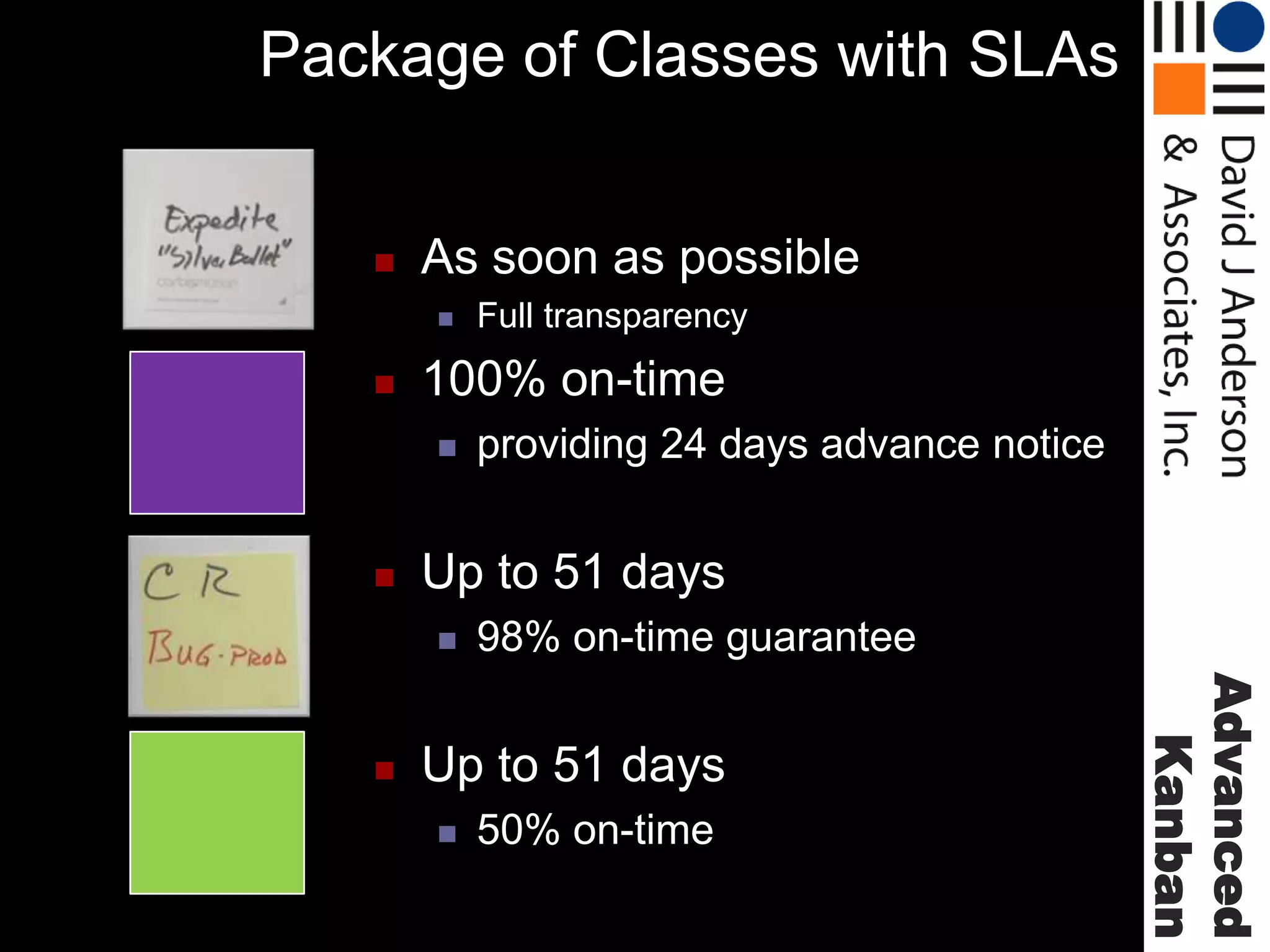

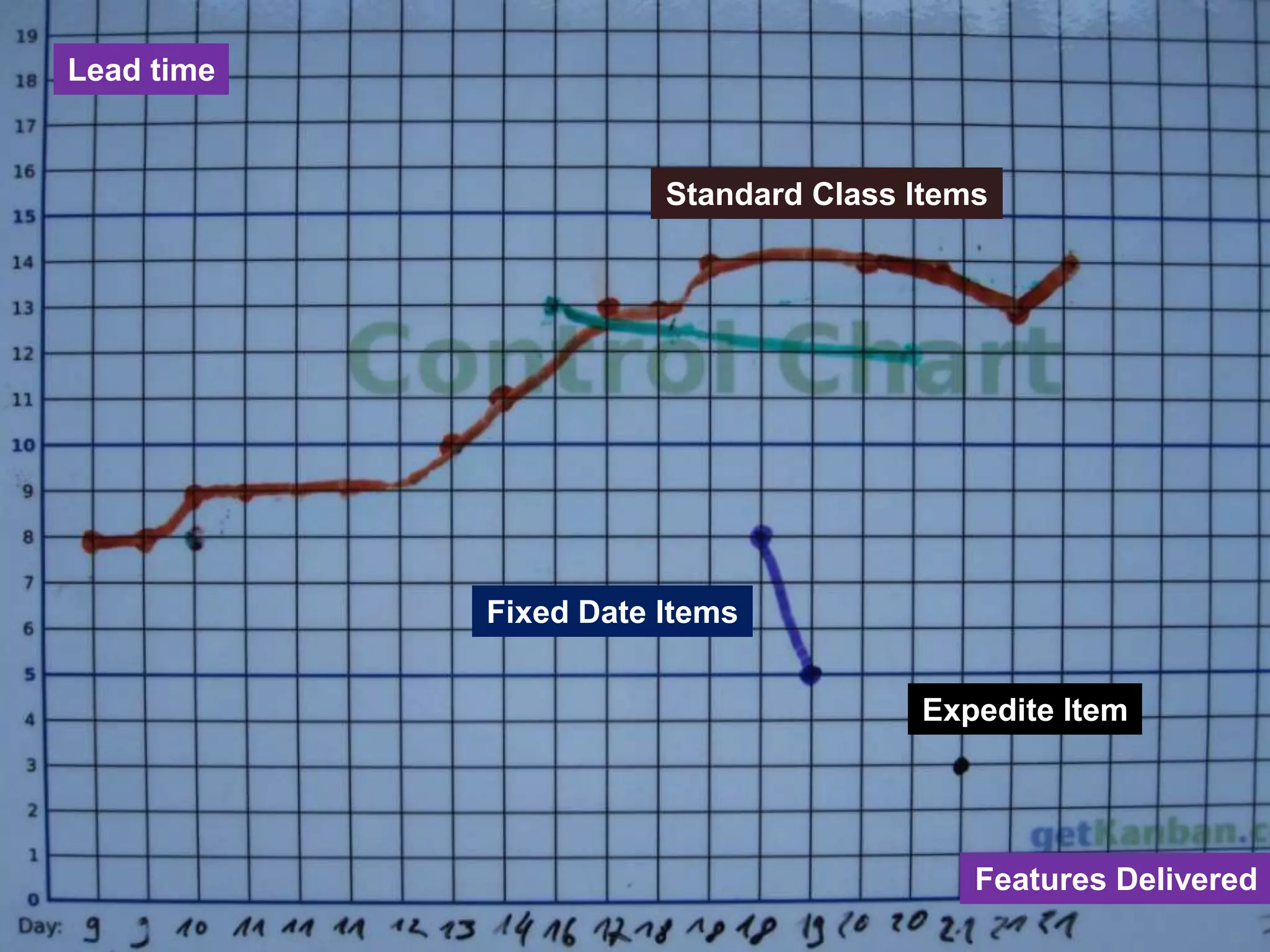

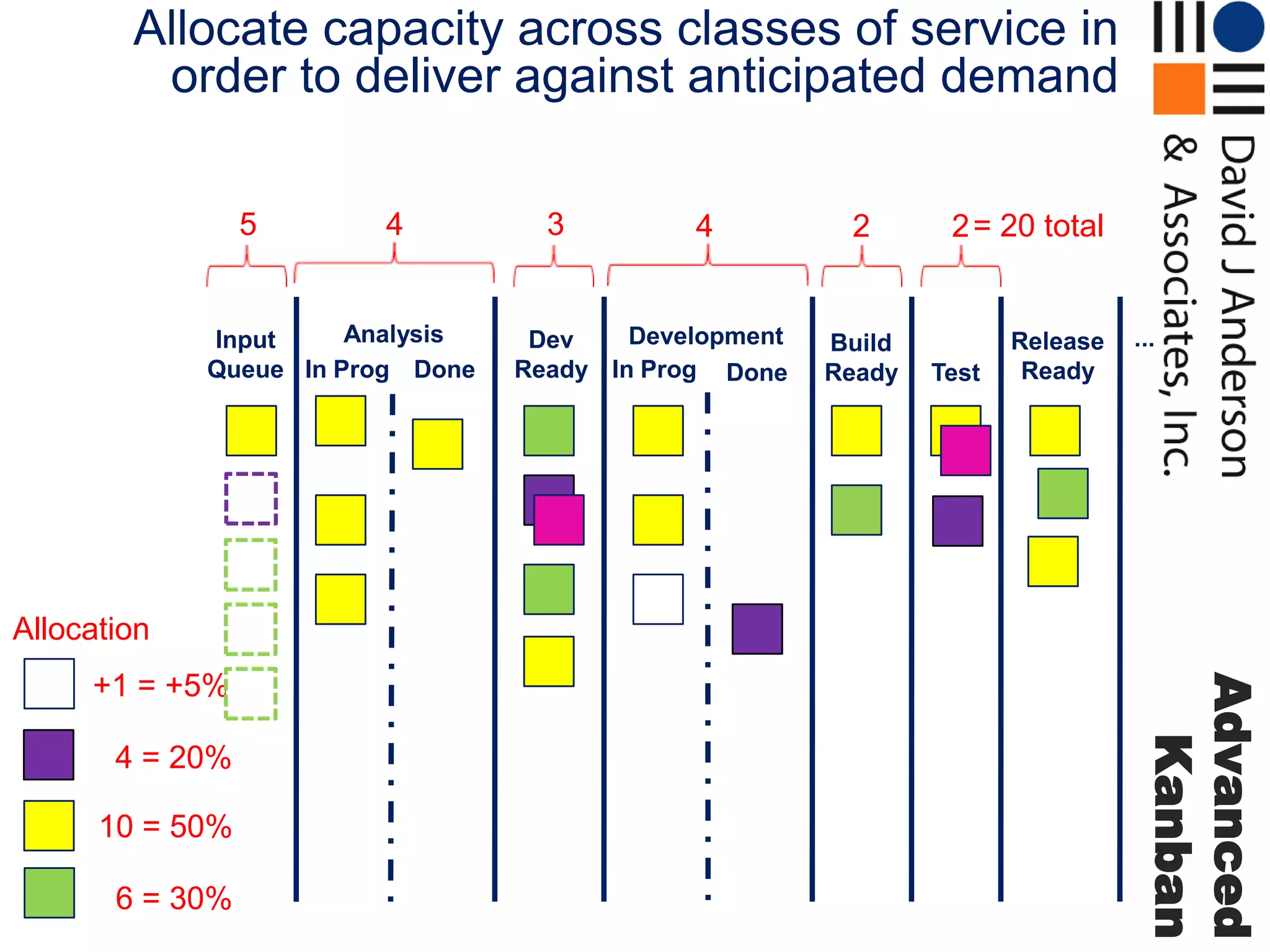

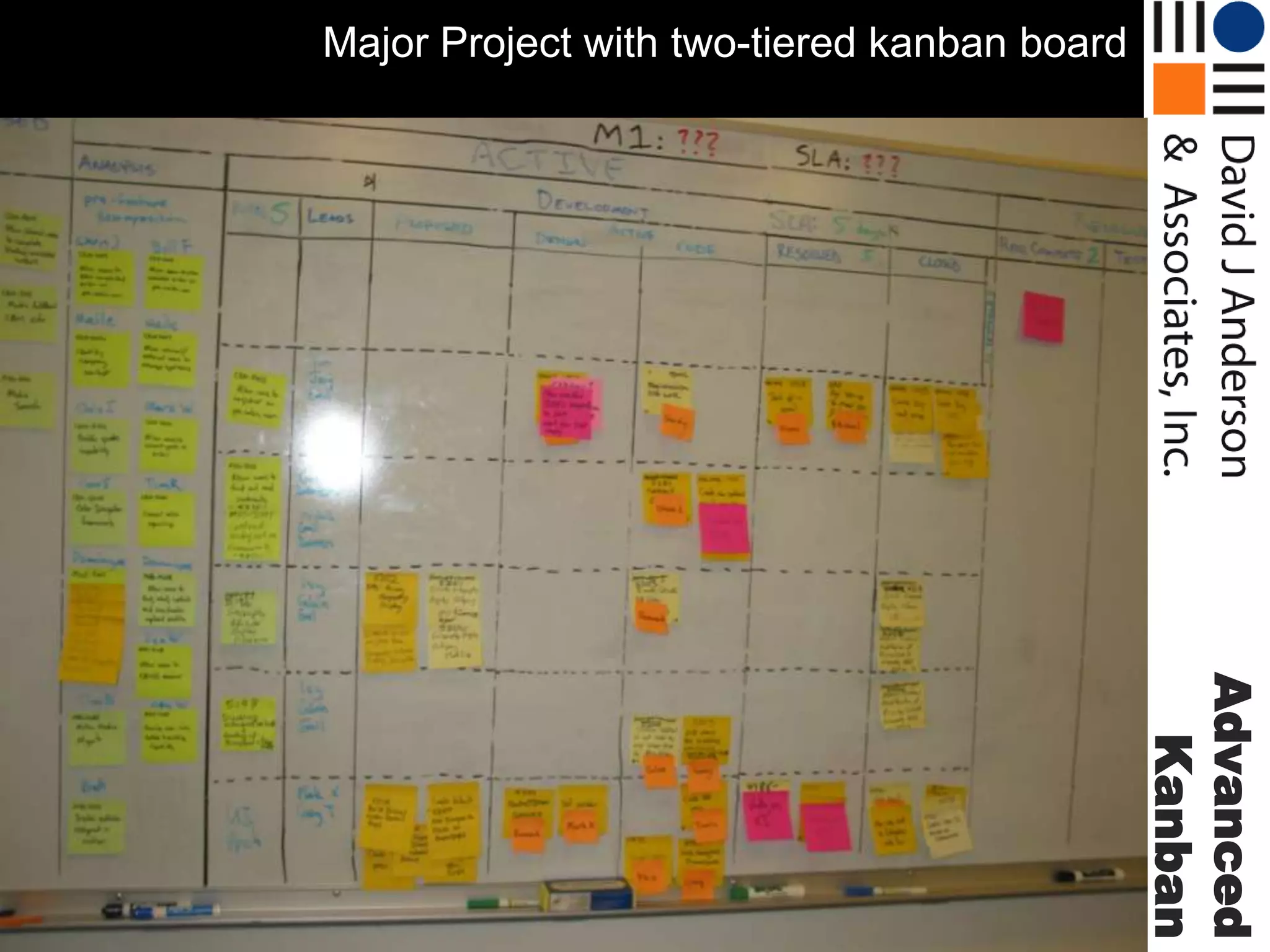

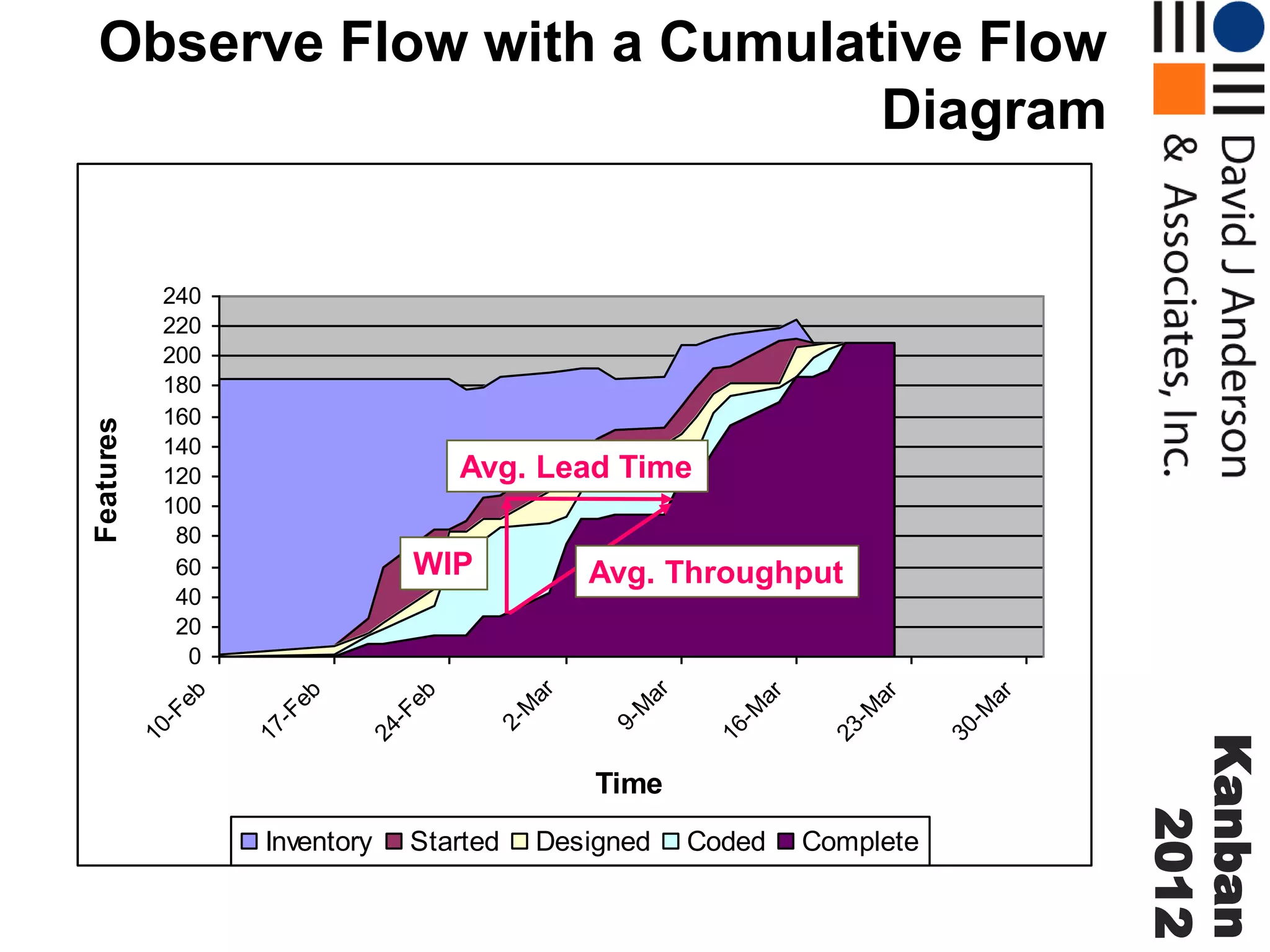

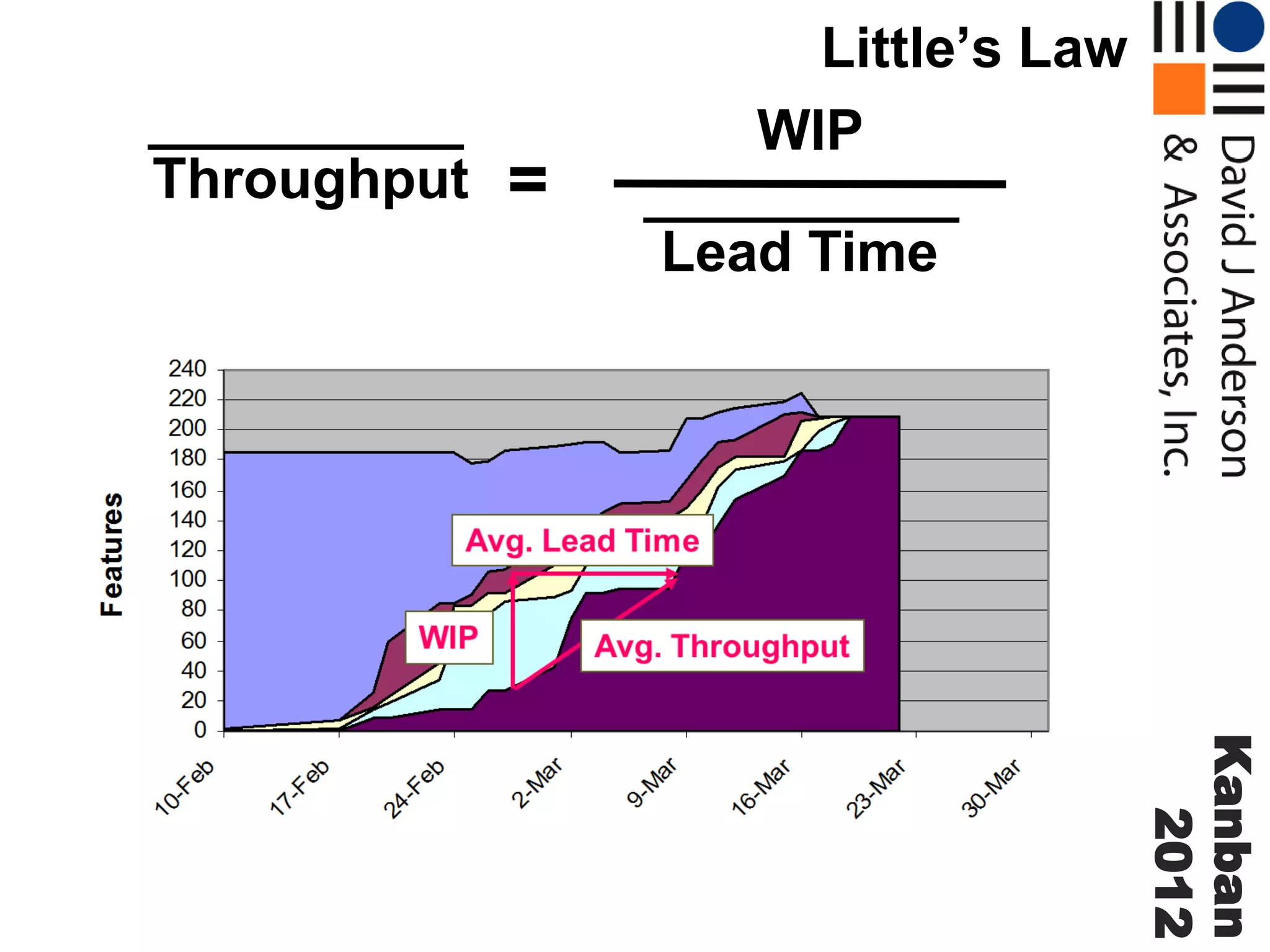

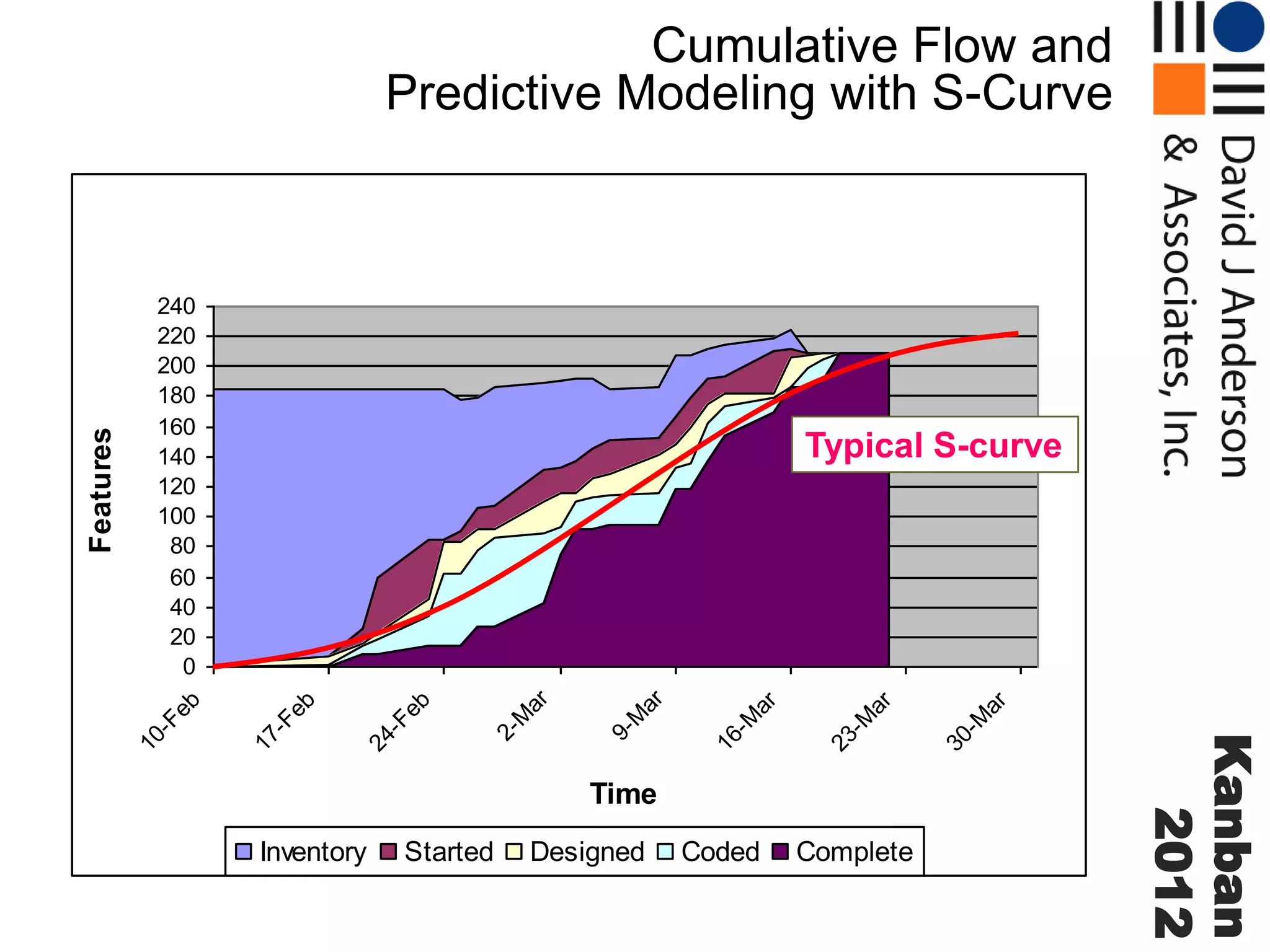

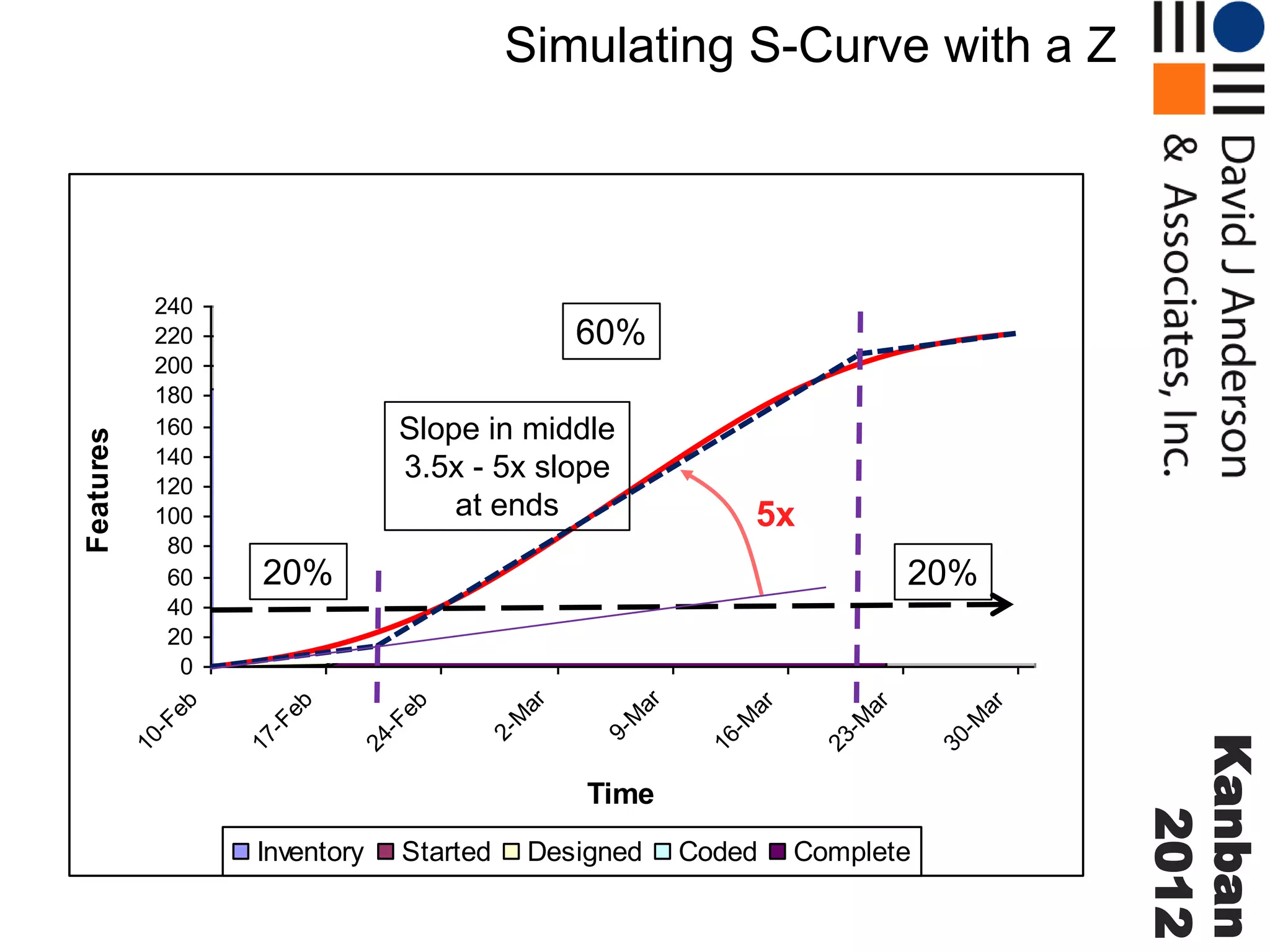

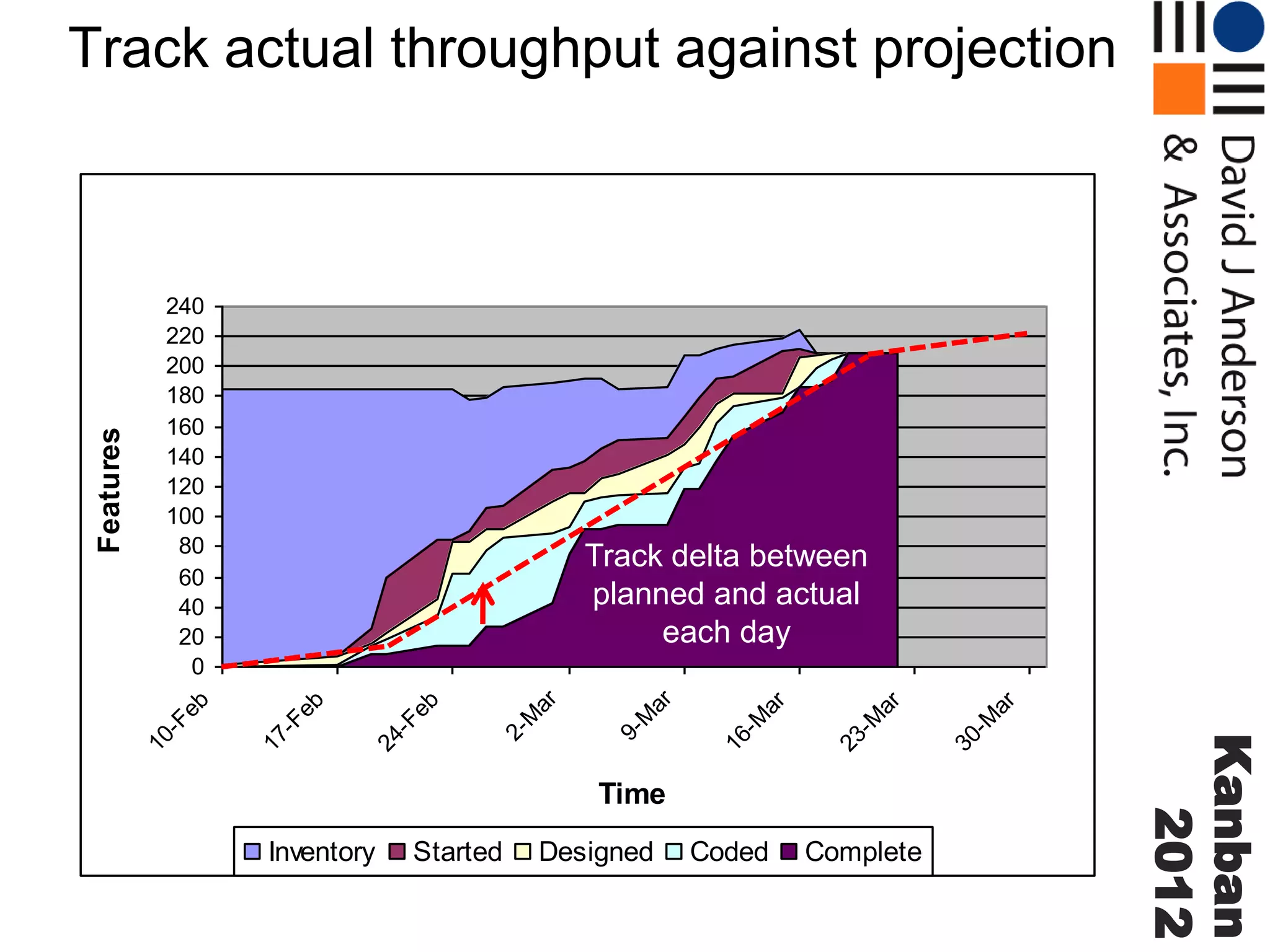

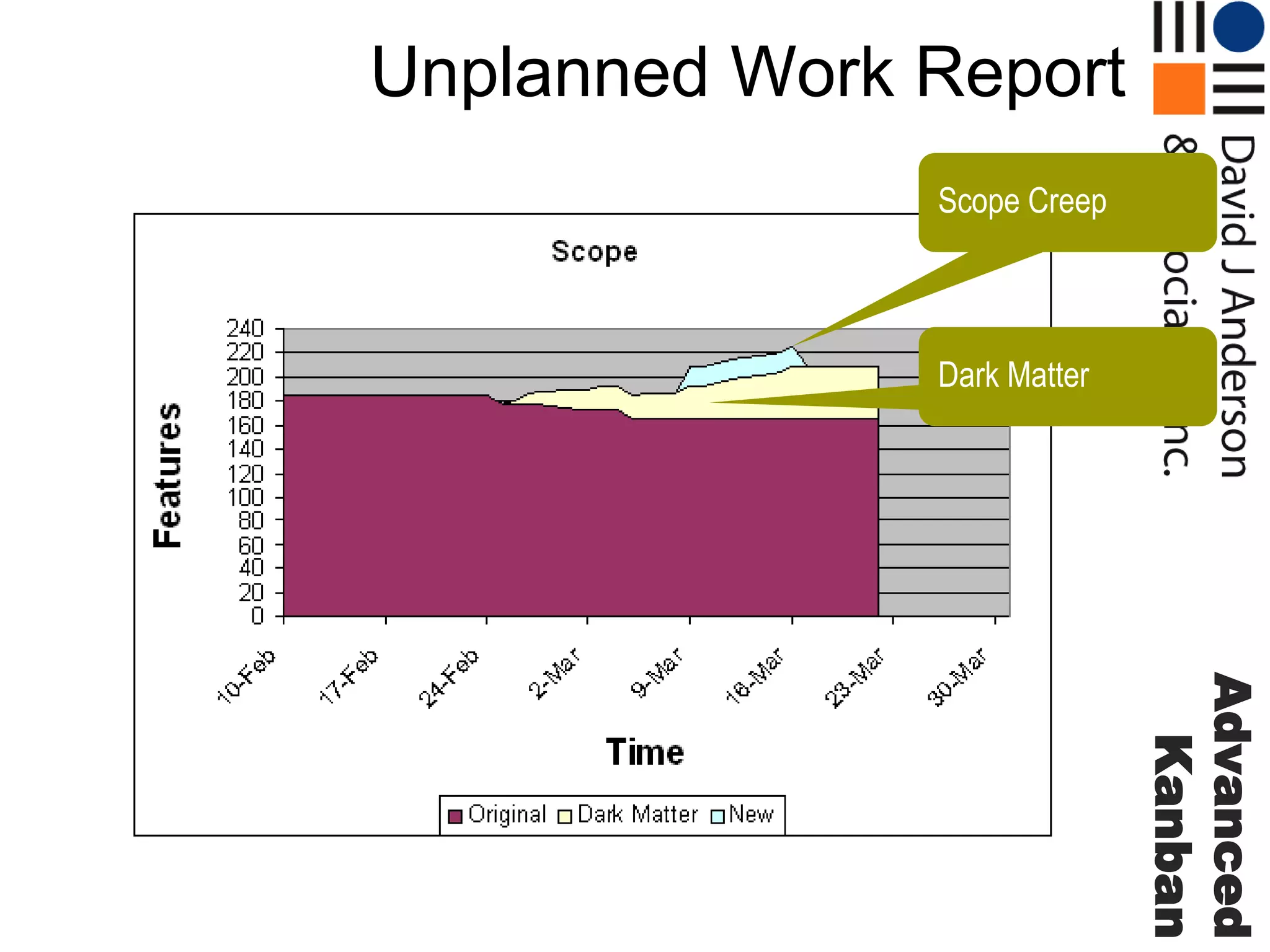

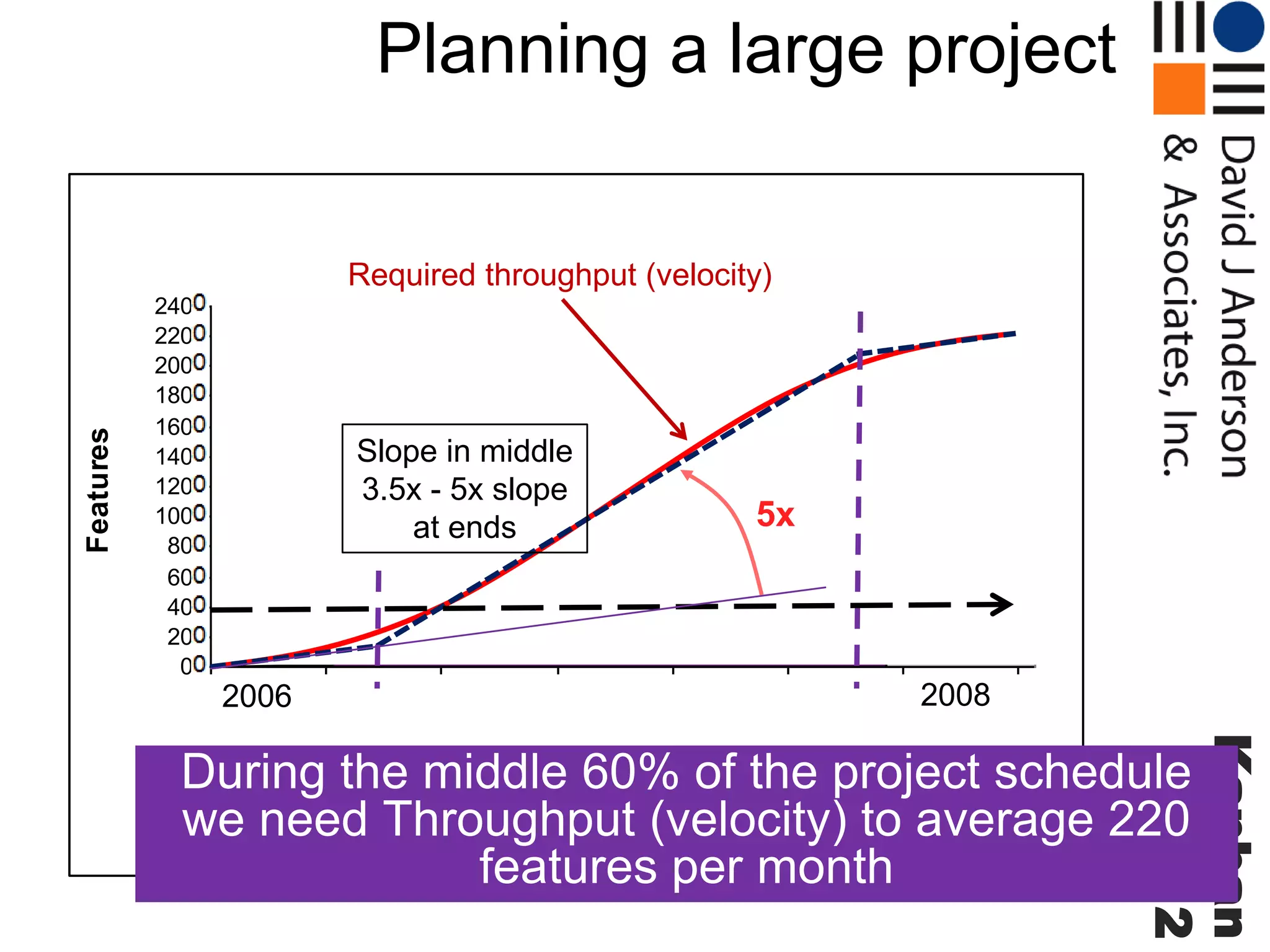

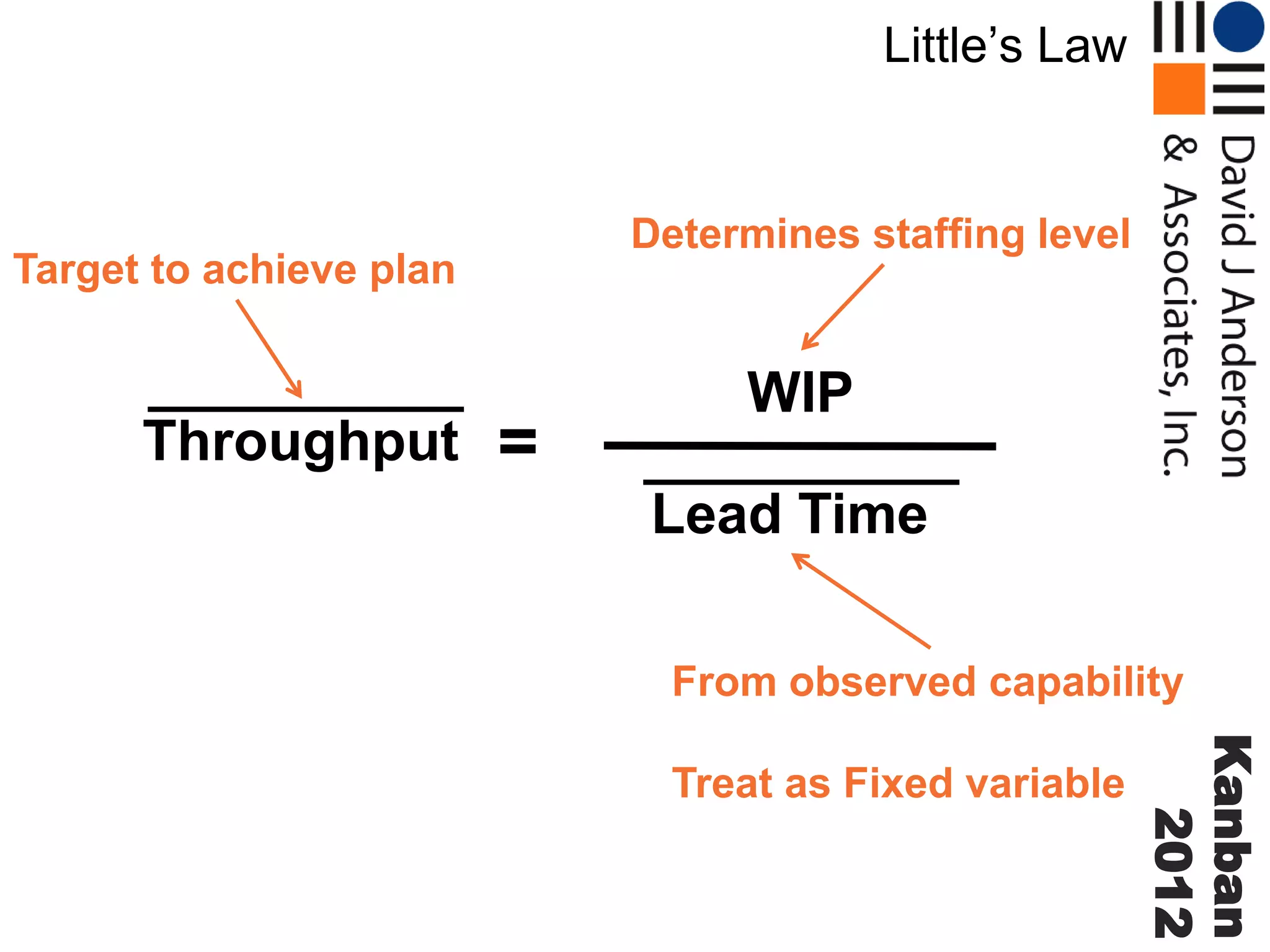

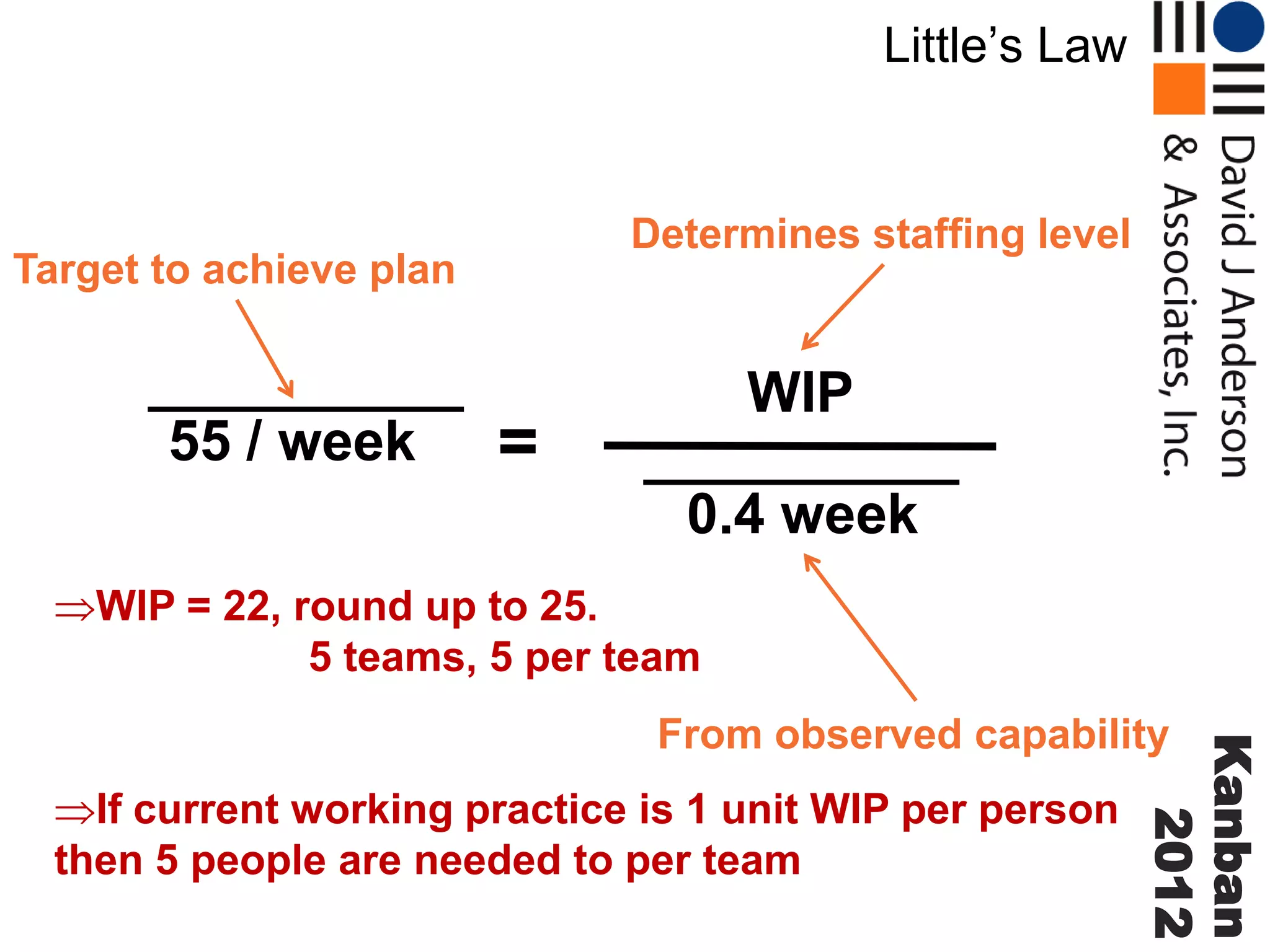

The document discusses advanced Kanban techniques for achieving predictability and measurement in various work types, including software maintenance and major projects. It emphasizes the importance of establishing a regular delivery cadence, strong configuration management, and effective deployment capabilities. The author, David J. Anderson, provides insights into modeling throughput and staffing levels based on observed capability while advocating for transparency and the management of work in progress.