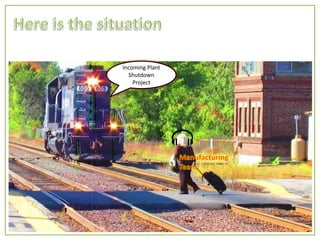

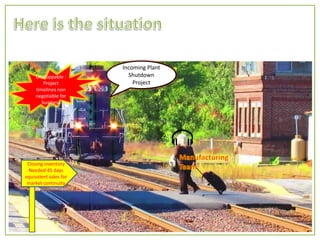

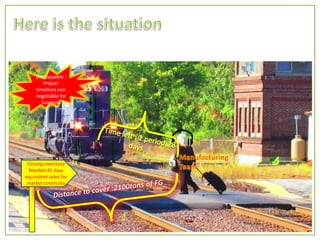

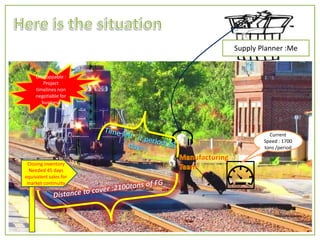

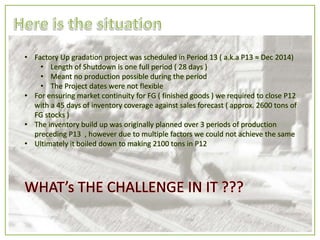

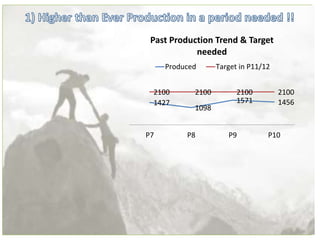

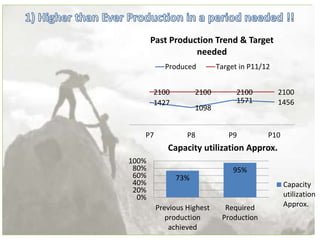

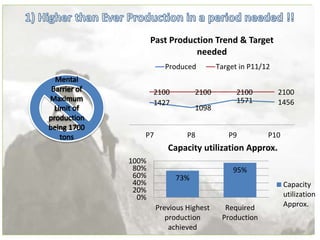

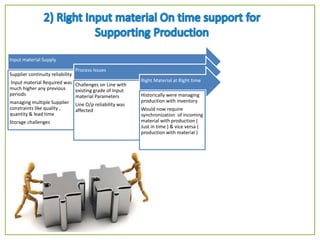

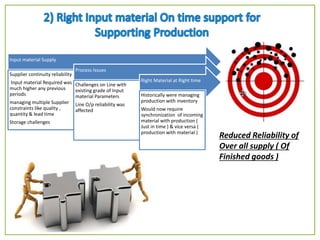

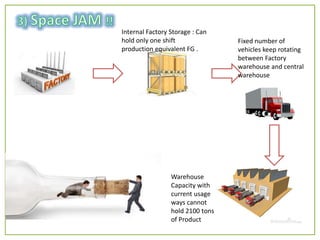

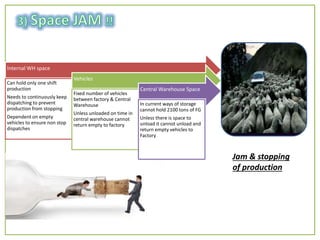

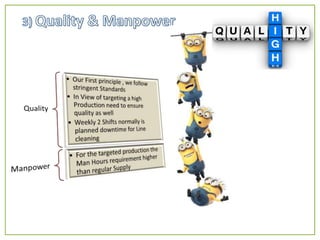

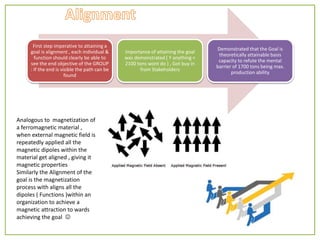

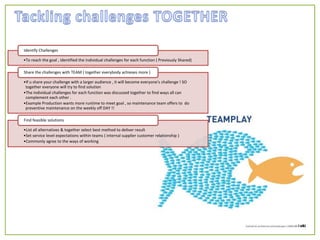

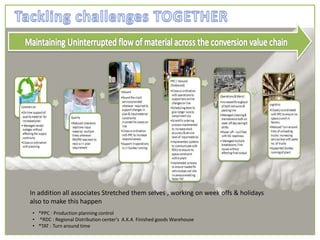

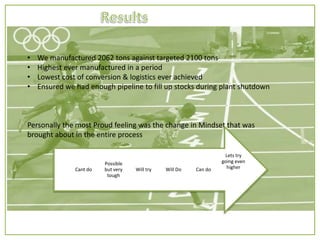

The document discusses a factory shutdown project where no production would be possible for 28 days. To ensure market continuity, 2600 tons of finished goods inventory was required. This necessitated producing 2100 tons in the preceding period, which was significantly higher than past production levels. It outlines the challenges around input materials, storage capacity, and identifies stakeholders. It then details how the national supply planner aligned all functions to complement each other and find solutions to achieve the goal through open communication and collaborative planning. Their efforts resulted in producing 2062 tons, the highest amount ever.