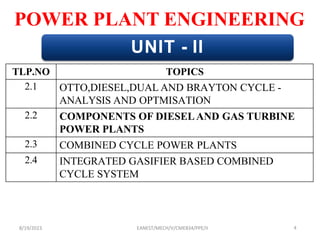

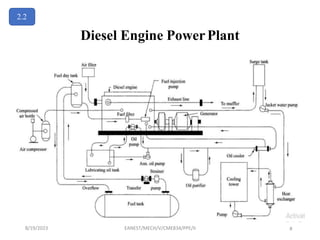

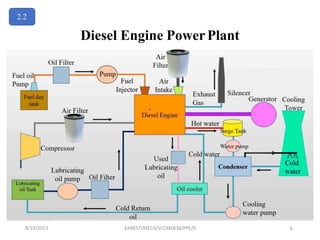

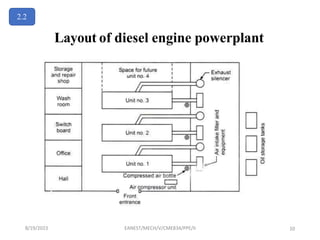

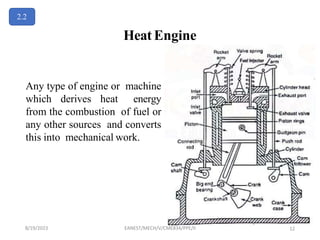

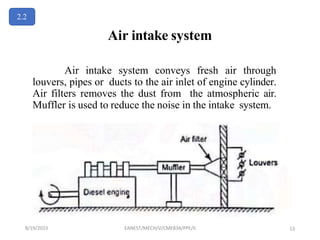

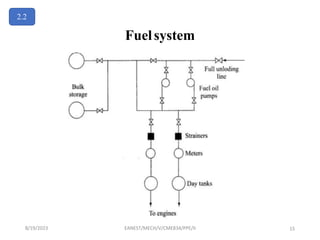

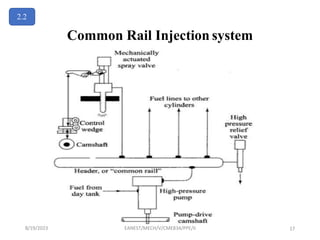

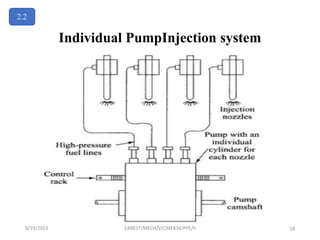

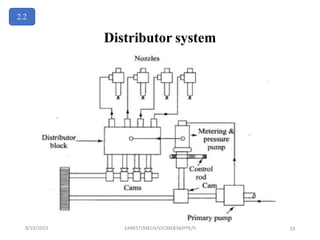

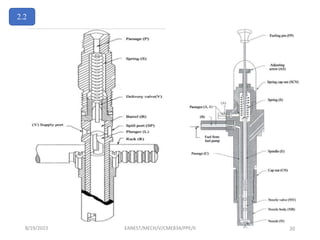

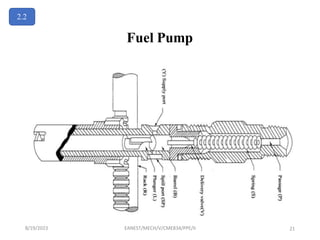

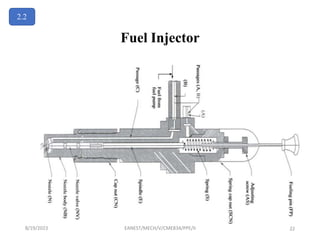

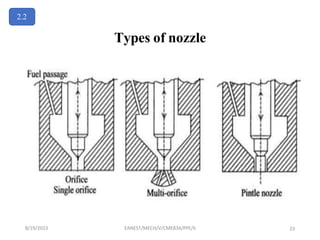

The document discusses the components of diesel engine power plants. It describes the various systems that are part of diesel engines like the air intake system, fuel system, injection system, lubrication system and cooling system. It explains the working of key components such as the fuel pump, injector and nozzle. The summary provides an overview of the layout and major components of diesel engine power plants.