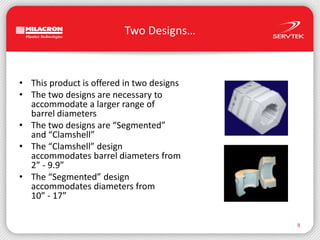

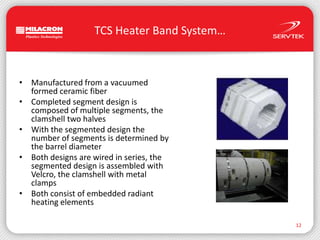

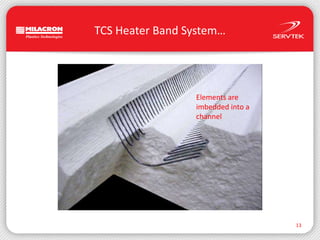

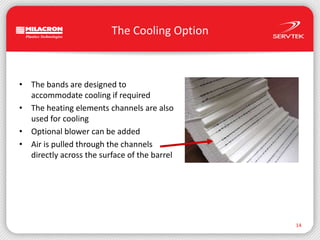

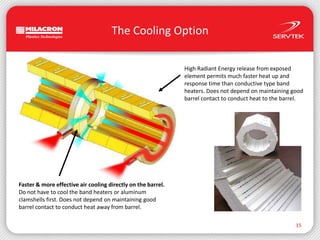

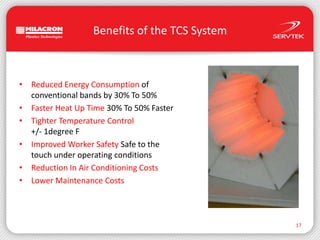

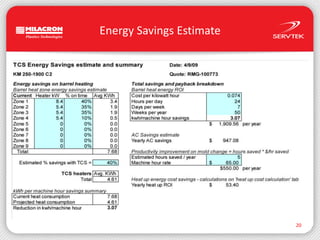

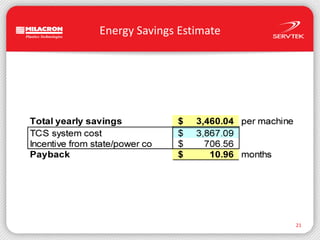

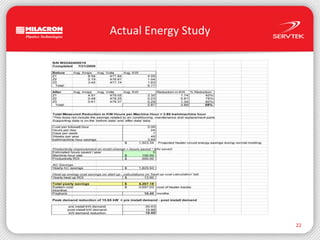

The TCS Heater Band System provides an energy efficient alternative to conventional barrel heating bands for plastic injection, blow molding, and extrusion machines. It uses embedded radiant heating elements in a ceramic fiber material to heat machine barrels. This allows for 30-50% reduced energy usage compared to conventional bands, faster heat up times, tighter temperature control, and optional efficient cooling. Customer case studies show payback periods of less than two years. The TCS system can be used on machines of any make and model to lower energy costs and improve productivity.