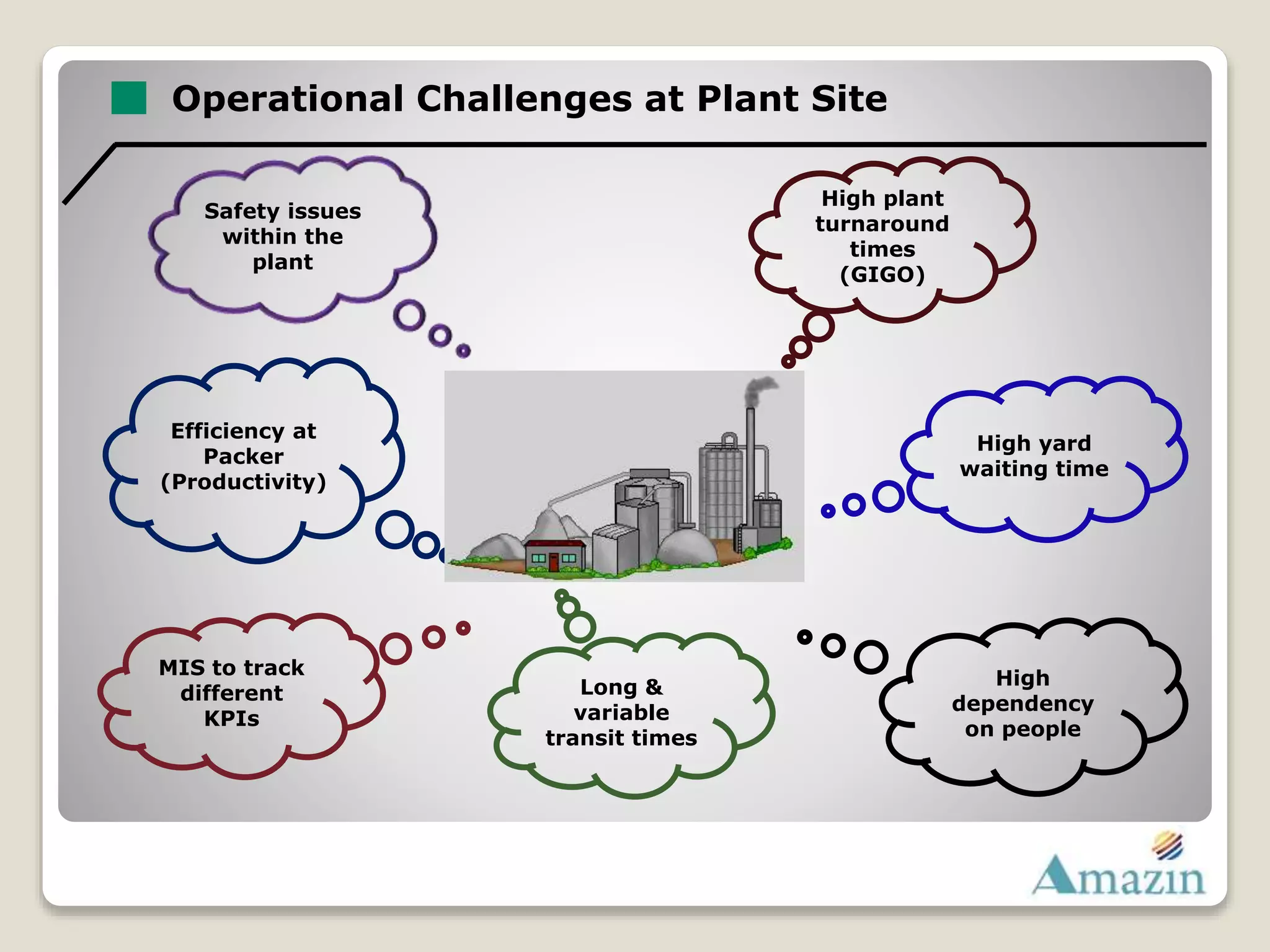

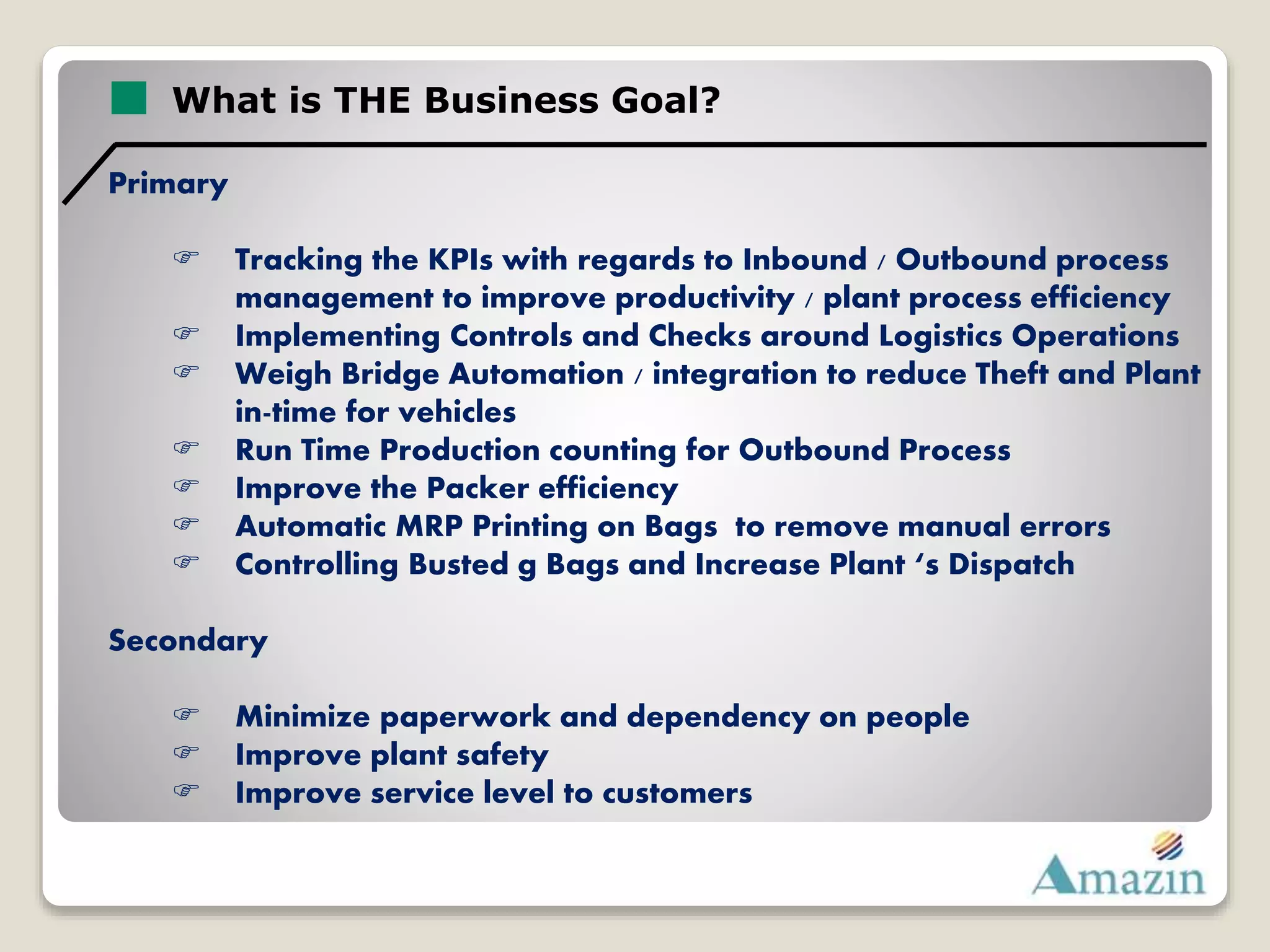

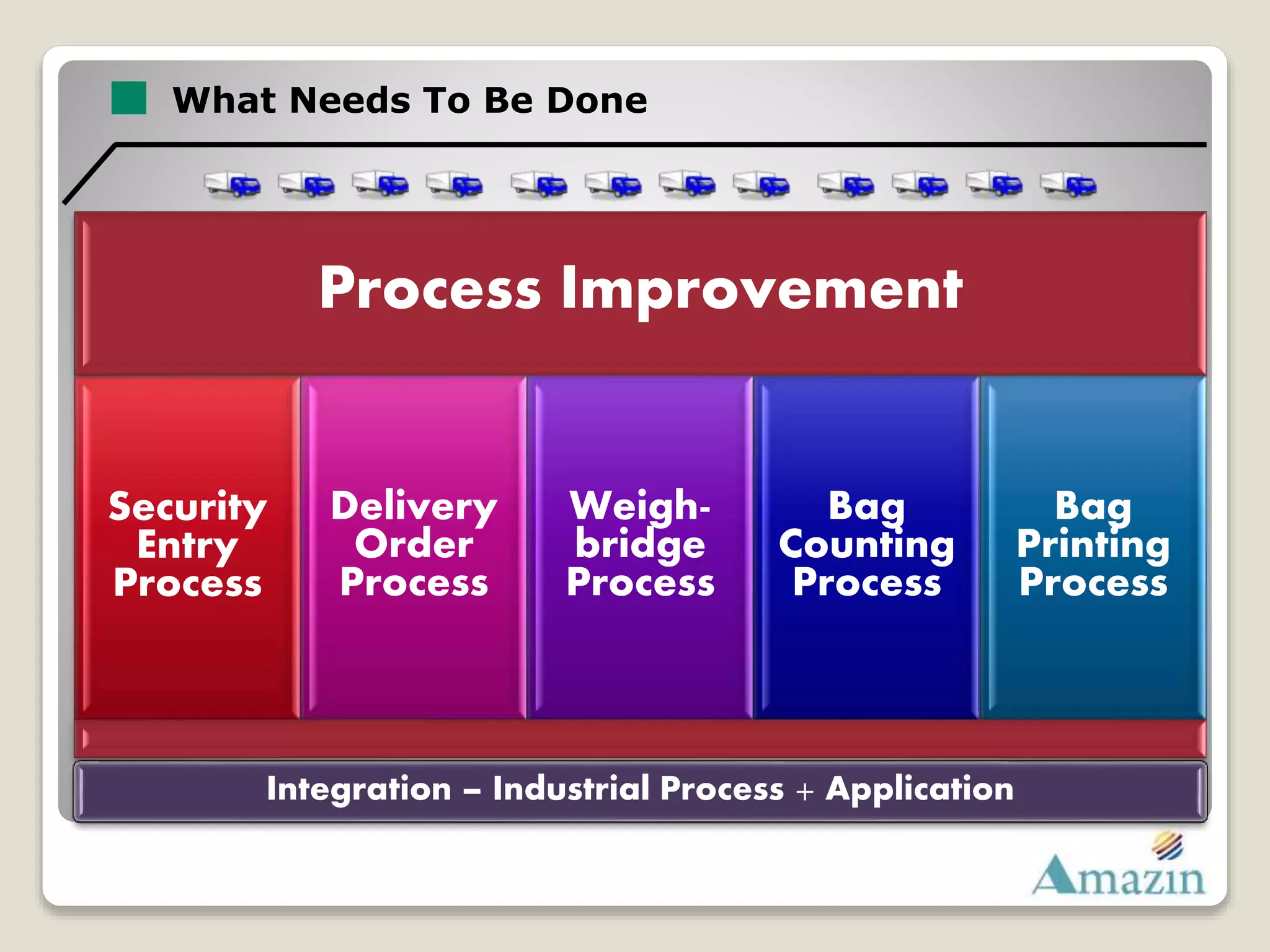

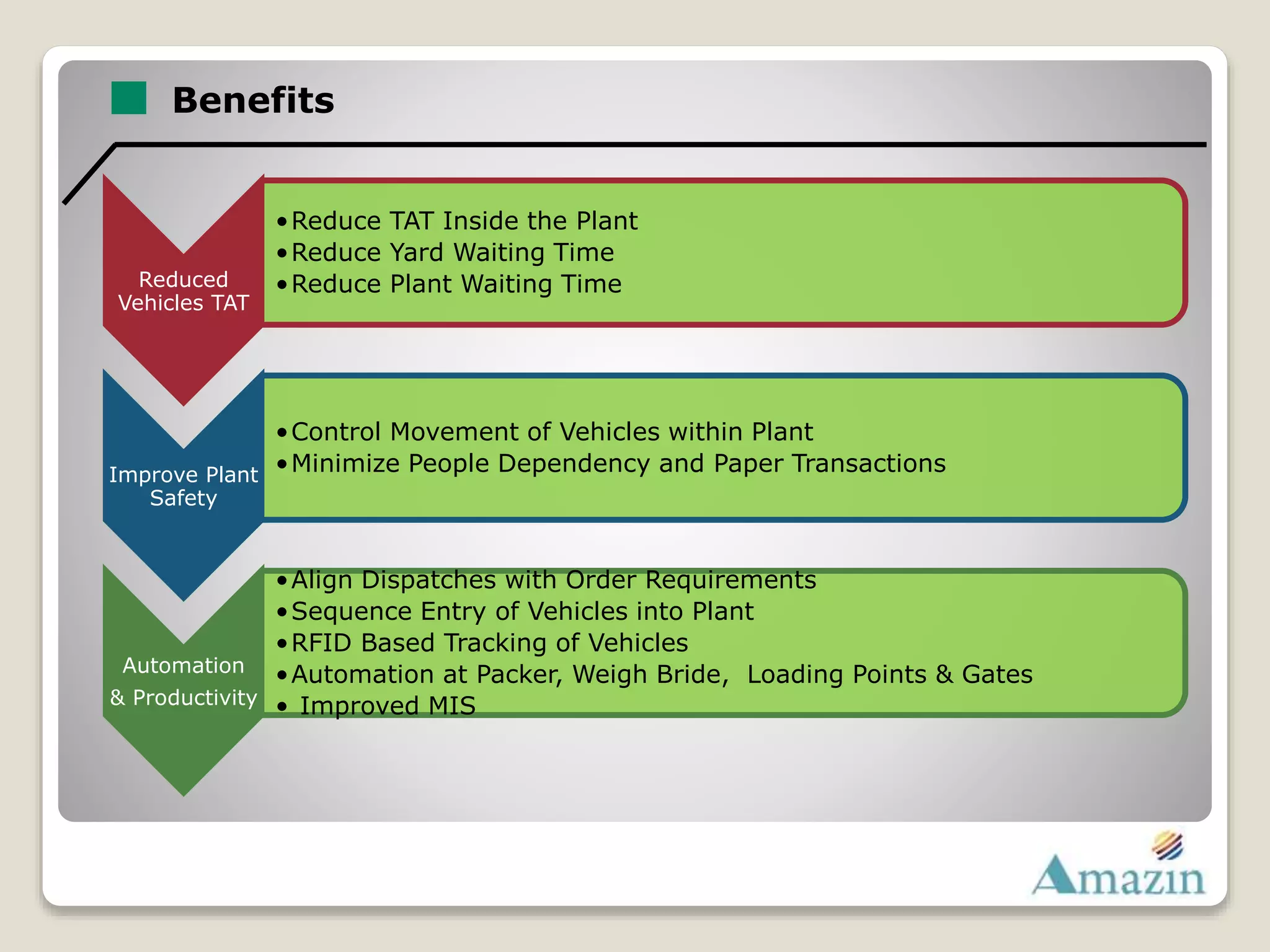

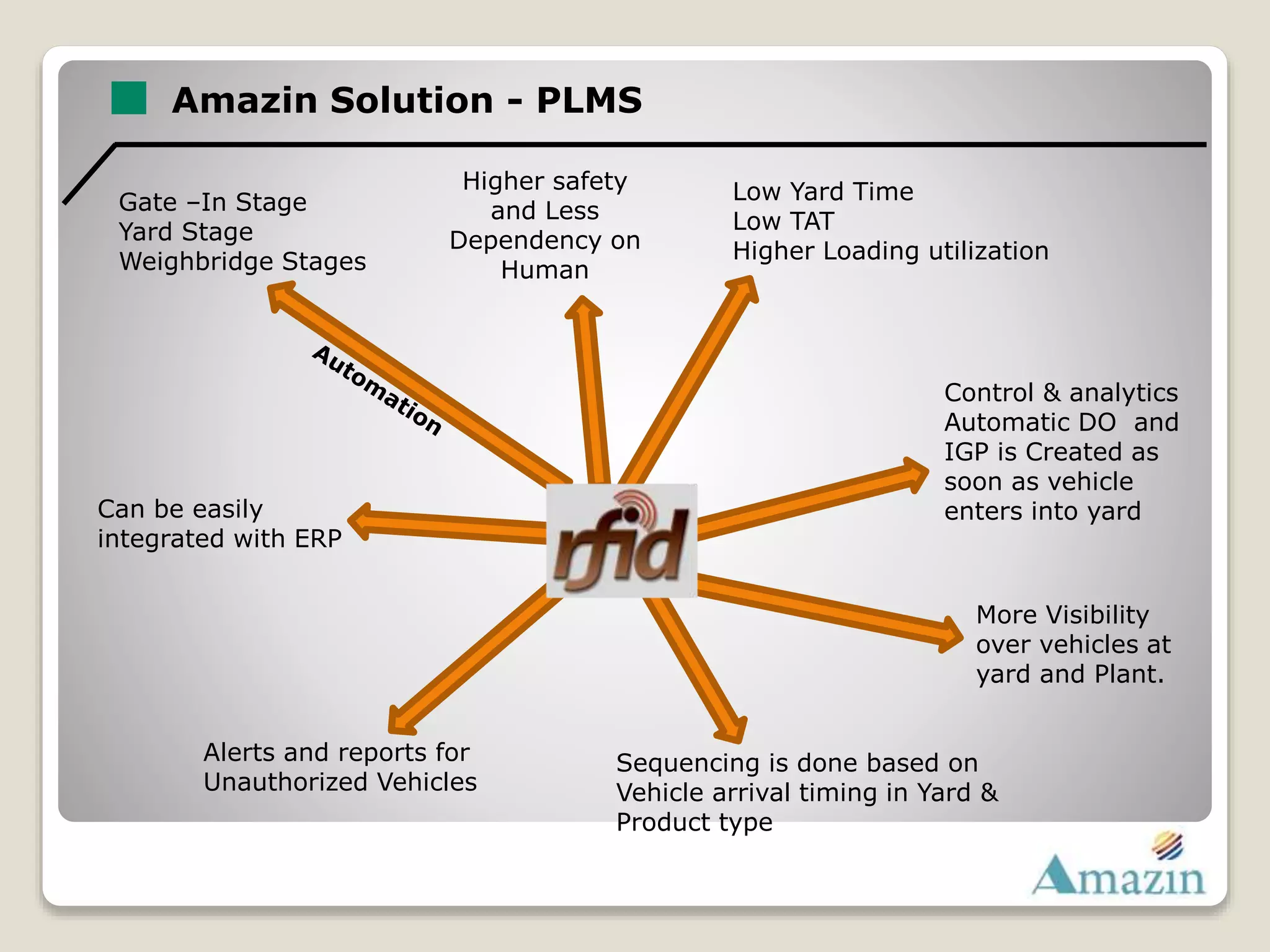

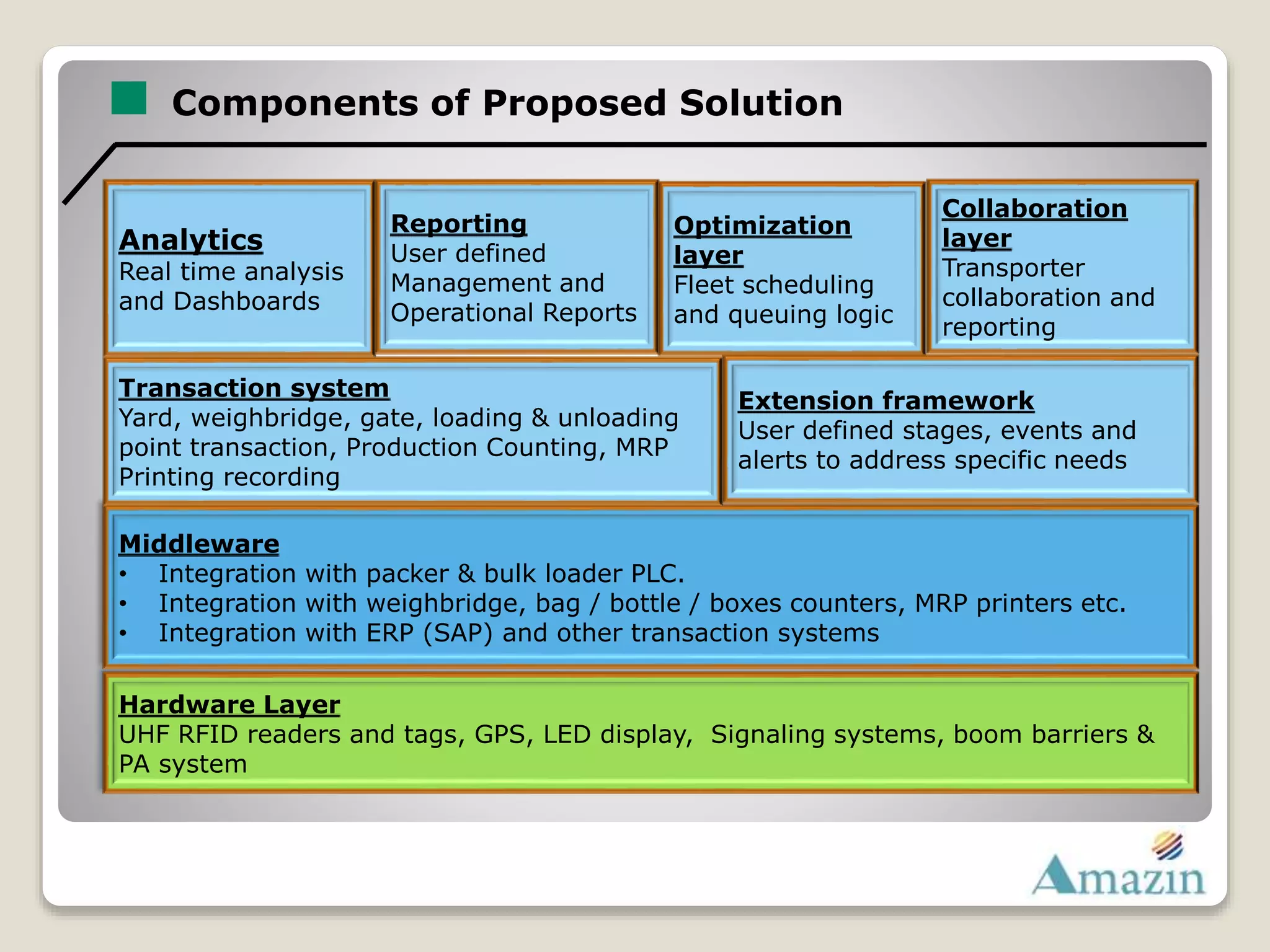

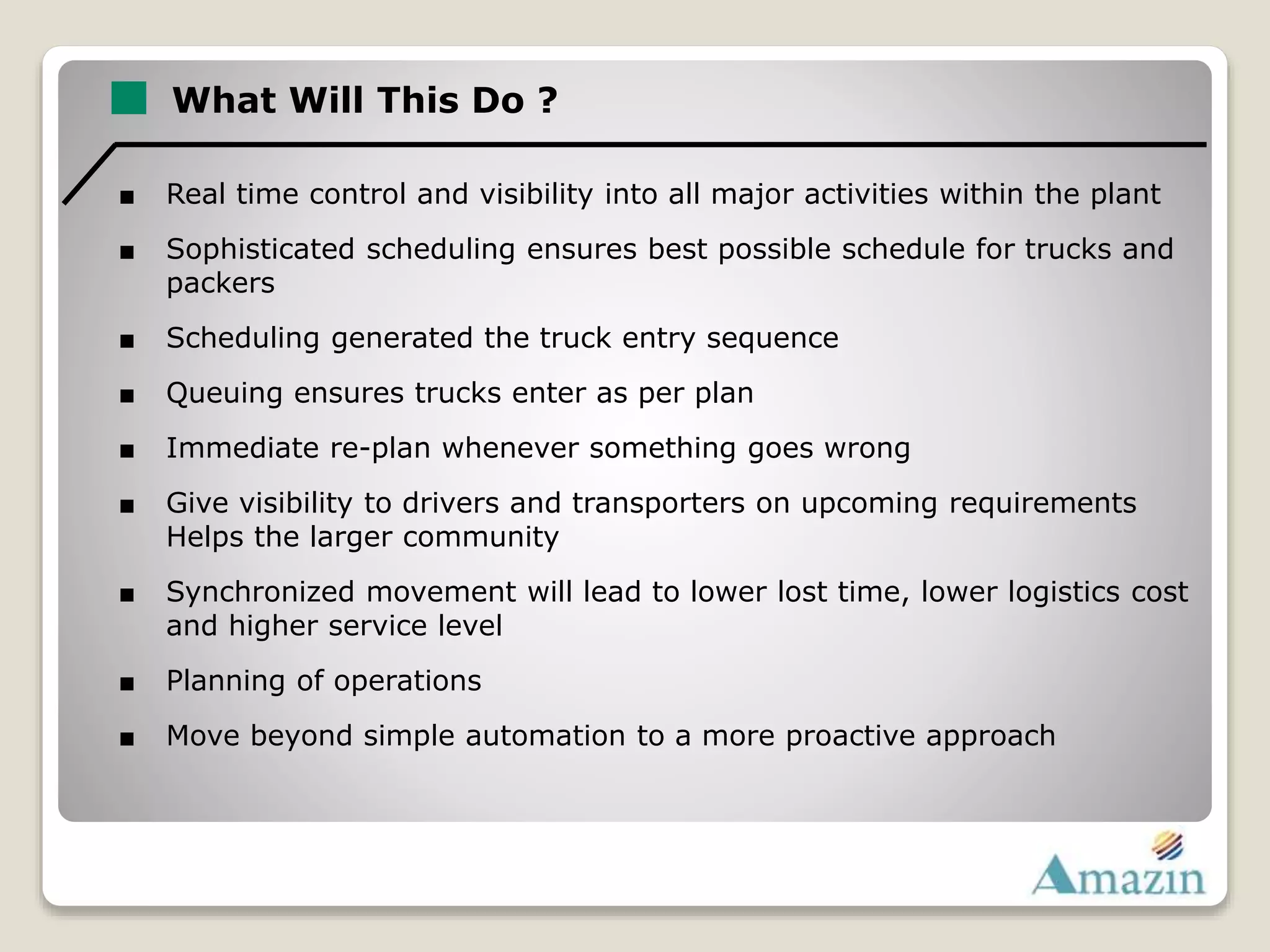

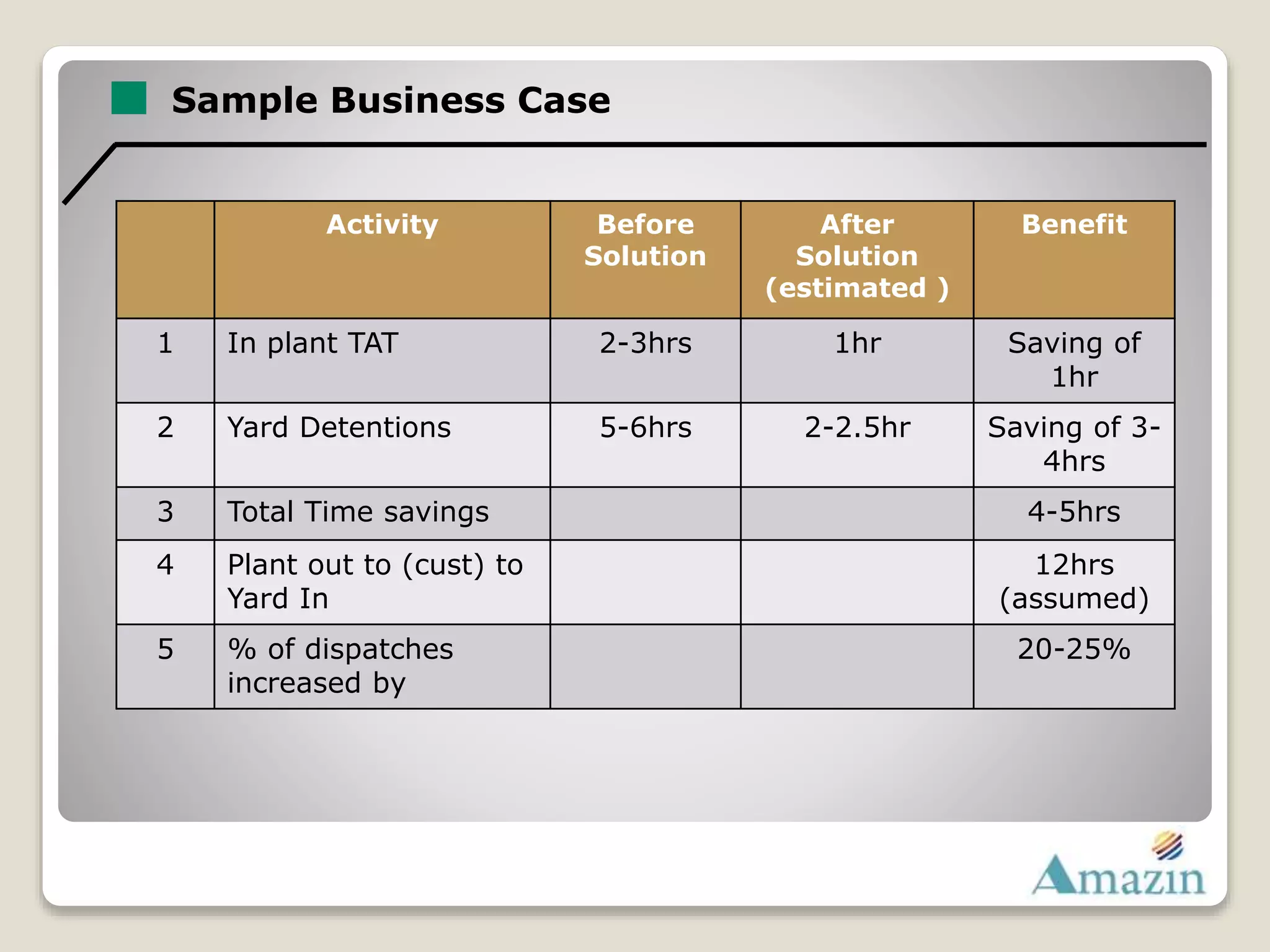

The document proposes a Plant Logistics Management System (PLMS) to address various operational challenges at plant sites such as high turnaround times, safety issues, and dependency on people. The primary goals of the PLMS are to track KPIs for inbound/outbound processes, implement process controls, automate weigh bridges and gates, and improve packer efficiency. The proposed solution utilizes RFID, GPS, and an integration platform to automate processes like vehicle entry, weighing, bag counting, and MRP printing. This is expected to reduce turnaround times by 30-90 minutes, lower yard waiting by 2-3 hours, improve loading utilization to 90-95%, and increase on-time deliveries and dispatches by