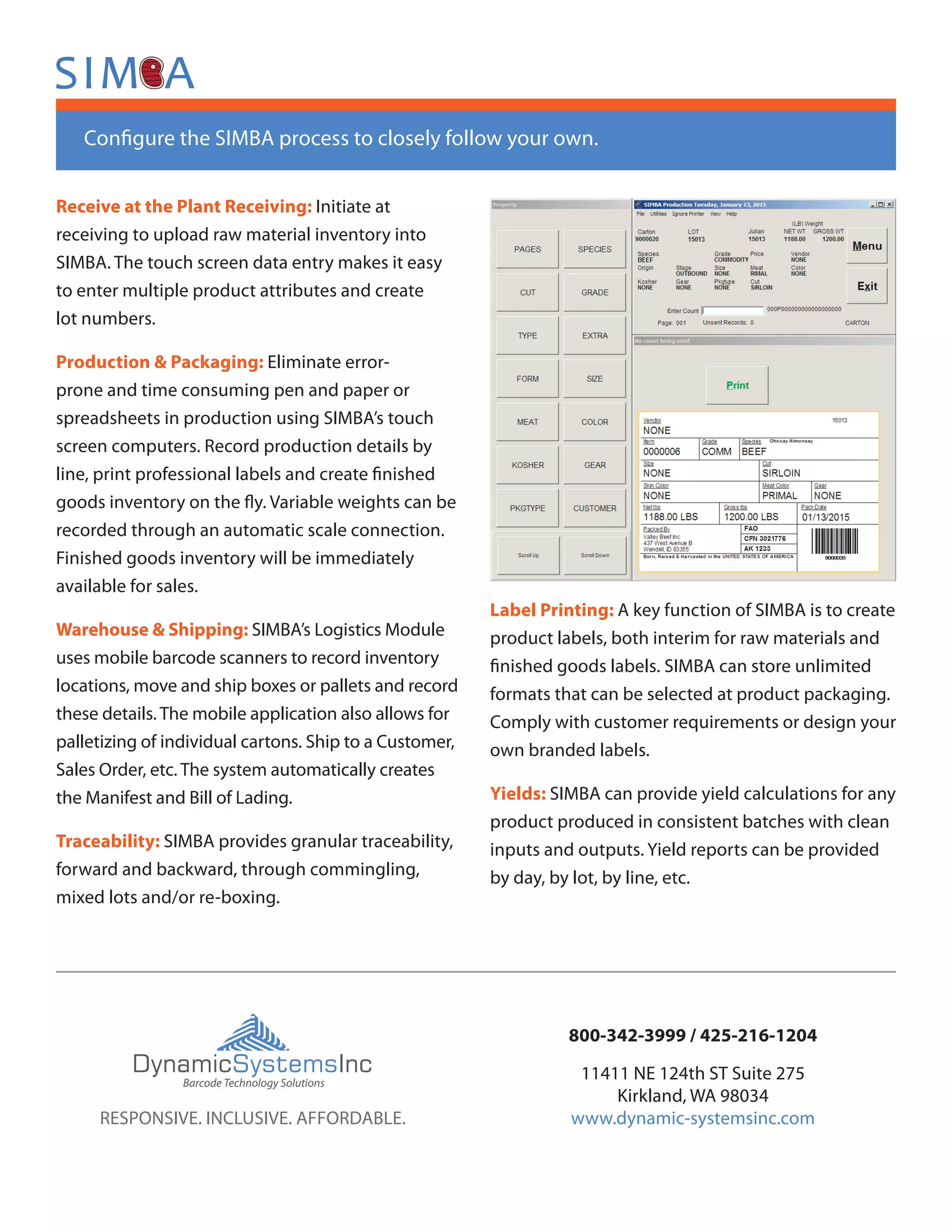

Simba offers an automated real-time solution for meat packers that enhances productivity and traceability while eliminating manual data entry. The system provides end-to-end traceability, accurate inventory management, and streamlined shipping processes, including professional labeling and reporting functionalities. It also integrates seamlessly with existing equipment and ERP systems, allowing for real-time data collection and improved operational efficiency.