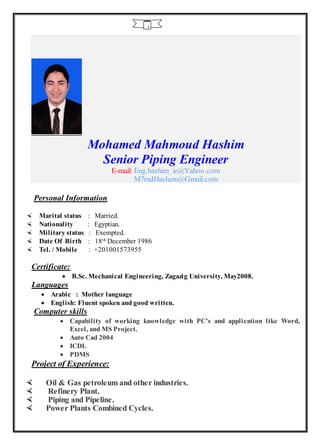

Mohamed Mahmoud Hashim is a senior piping engineer with over 10 years of experience in oil, gas, and power plant projects. He is currently working on the Burullus Power Plant project in Egypt as the senior site piping engineer and assistant technical office manager, where he is responsible for supervising piping installation quality and assisting with punch lists, testing, and as-built drawings. Previously, he has worked on refinery and petrochemical projects in Egypt and the UAE, gaining experience in piping engineering, maintenance, and construction management. He is proficient in AutoCAD, piping codes and standards, and has safety and inspection certifications.

![2

Fields of Experience

Good working and technical knowledge of Mechanical, Piping and Pipeline Installation

and familiar with including application of industrial standards ASME, API, ANSI, DN,

and other international codes & standards.

Co Prepare mobilization of plans for construction and follow-up for compliance.

Coordination with suppliers and subcontractors to ensure suitable delivery time,

mobilization/demobilization etc.

Review construction documents, procedures, engineering drawings and

deliverables to assess construct ability and consistency with contract requirements

Recommended practices for this discipline.

Matching project requirements for construction engineering activities.

Participation in the development of the installation planning, to establish the

sequence and duration of Mechanical activities and optimize project execution.

Monitoring performance against milestones, resolving contractual and other

problems that might arise during execution with System Operations and Project

Management.

Participation in taking necessary action to adjust project schedule to account for

changing priorities, delays and other contingencies, ensuring that the costs are within

approved budget levels.

Managing and directing all site mechanical construction activities.

Provide commercial and technical input at the estimation stage and later managing

installation activities during the execution stage.

Participation in procurement technical evaluations and control all post-award

procurement activities related to allocated function ordinate with certification agencies

and warranty surveyors

Testing procedures as applicable to Fabricated Equipment & Piping with

knowledge of Isometric drawings, P& ID's and manpower record keeping.

Mechanical Construction Q /A.

Technical office management for mechanical and piping construction.

Previous experience in supervising multi national work force in Gulf region

Previous experience in execution projects during shut down.

Qualification and Training

1- Level (I) in Radiographic test method (R.T).

2- Level (I) in Magnetic particle inspection method (M.P.I).

3- Level (I) in Ultrasonic test method (U.T).

4- Course in “Welding & Inspection”

5- Course in “Project Management”

6- Course in Risk Based Inspection “

7- Safety Courses about “Fire Fighting – Vessel Entry -

Defensive Driving and First Aid” at CCIC Company.

8- LP Work Permit Receiver Course at CCIC Company.

9- HSE Appreciation Certificate from [CCC] for achievement 100,000,000 Man Hours

without LTA](https://image.slidesharecdn.com/a3973762-f55f-4912-b389-e1f90f633473-170202225833/85/CV_for_Mohamed_Hashim1-2-320.jpg)