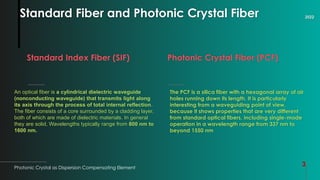

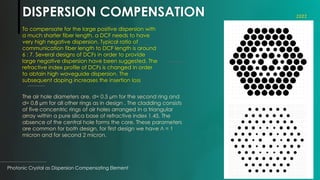

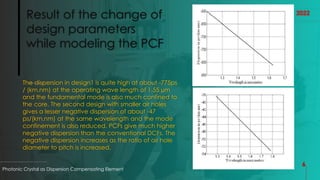

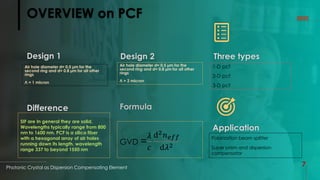

The document discusses photonic crystal fibers and their use as dispersion compensating elements in optical fiber links. It describes how photonic crystal fibers have a central defect region surrounded by air holes that allow them to guide light differently than conventional fibers. It also explains how the air hole design parameters, such as diameter and spacing, can be varied to achieve different dispersion characteristics, with larger air holes producing higher negative dispersion useful for compensating the positive dispersion in telecommunications fibers. The document provides examples of two photonic crystal fiber designs modeled with different air hole sizes and spacing that resulted in different levels of negative dispersion.