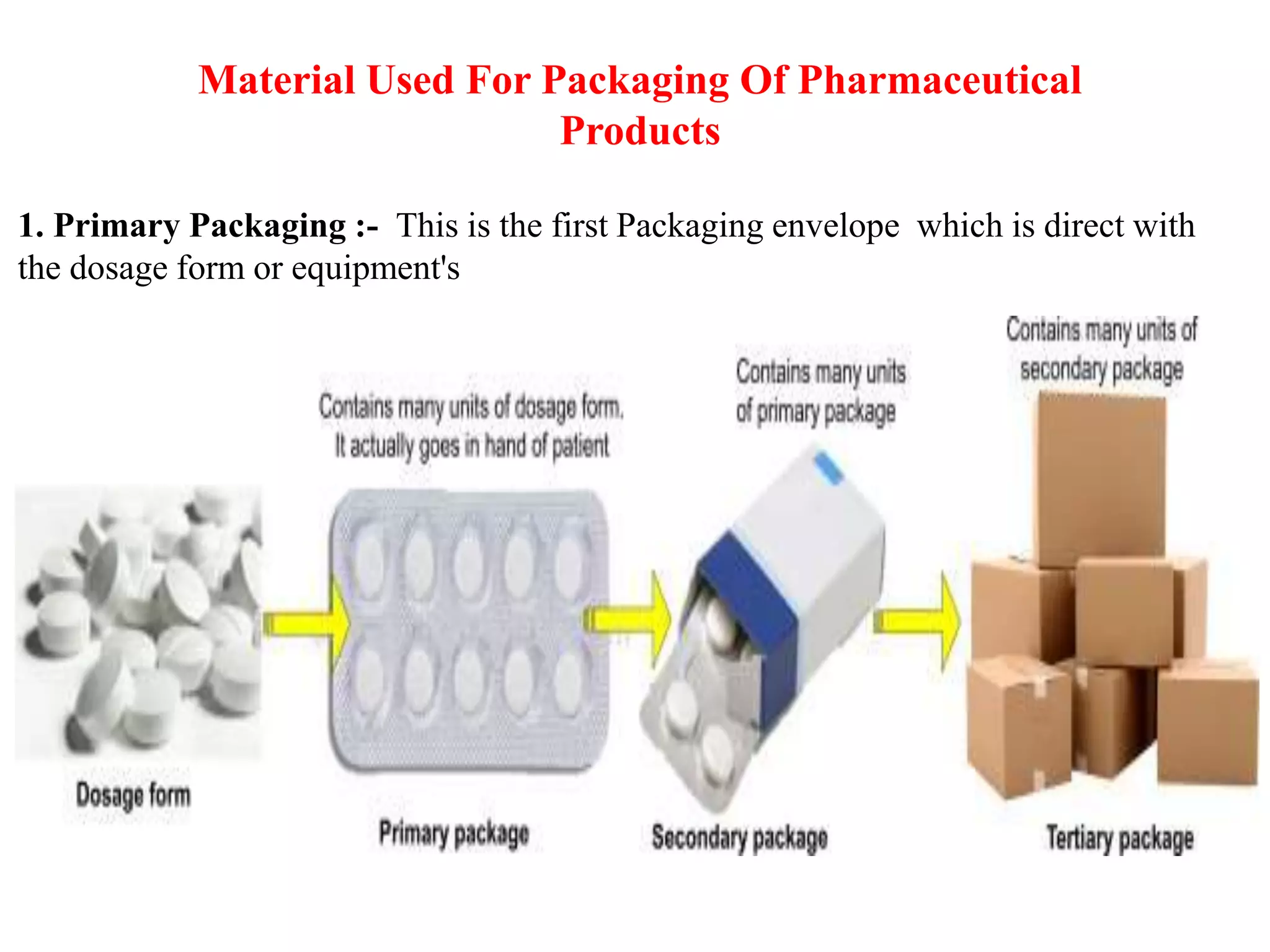

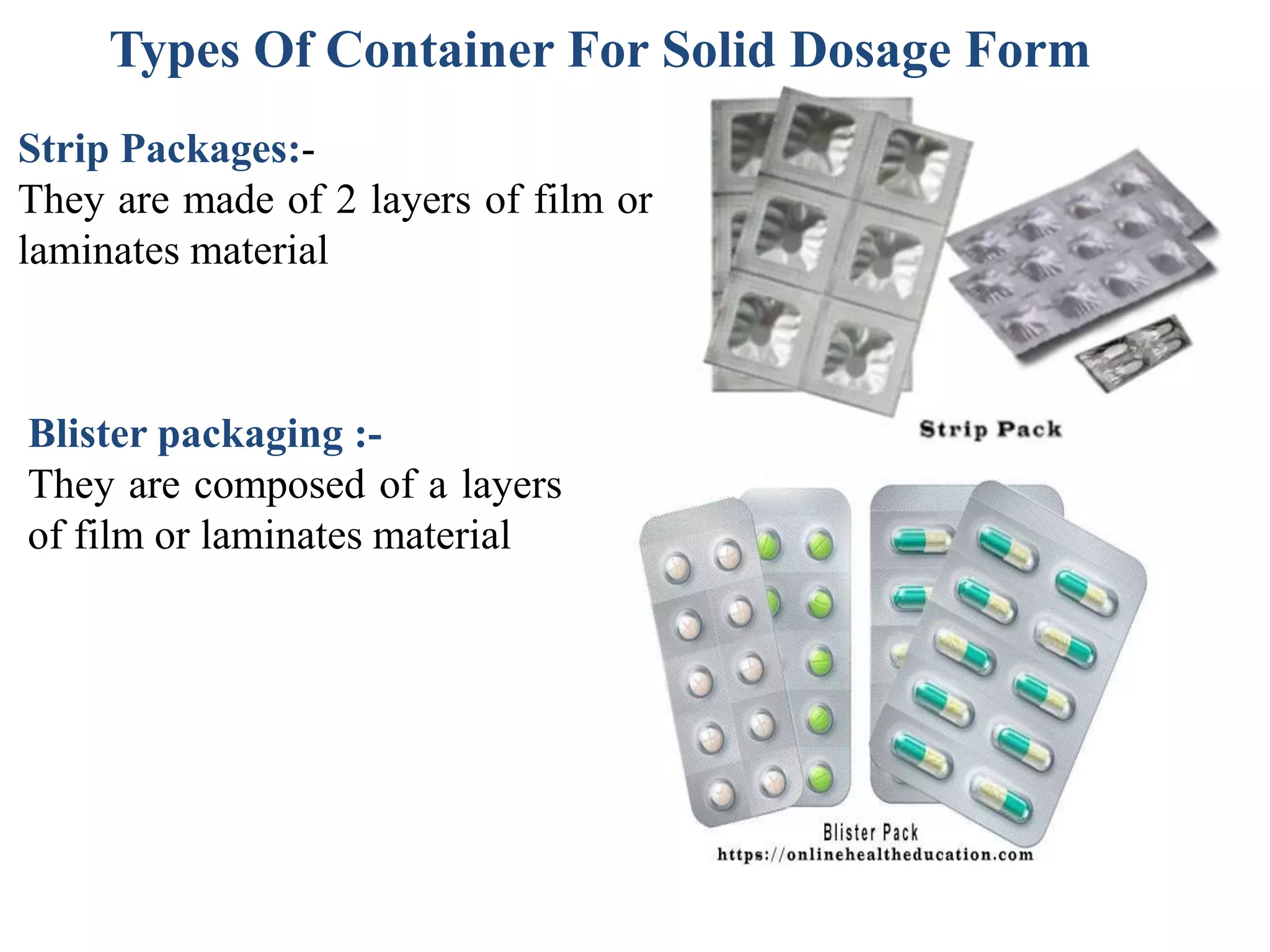

The document discusses the essential aspects of pharmaceutical packaging, including the types of packaging (primary, secondary, and tertiary) and materials such as glass, plastic, and metal. It outlines the requirements for good containers, types of closures, and specifics on aerosol packaging methods. Additionally, it details the characteristics and production methods for various container materials to ensure drug stability and safety during transportation and storage.