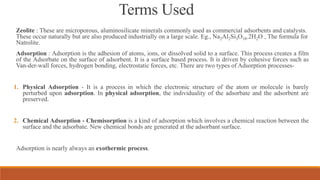

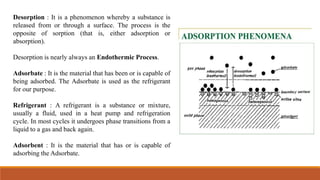

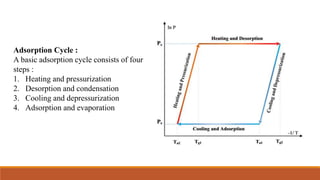

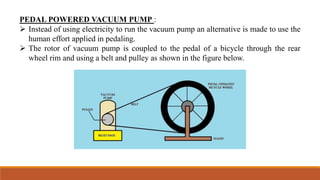

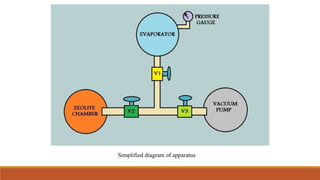

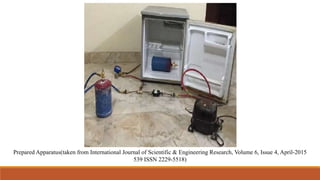

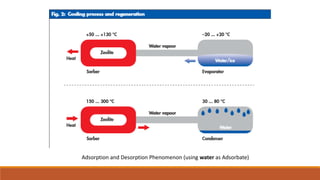

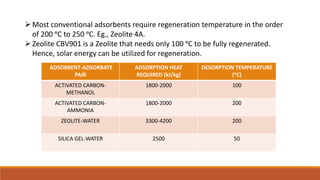

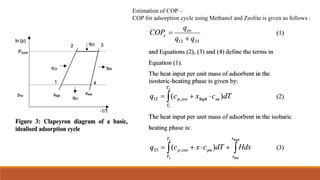

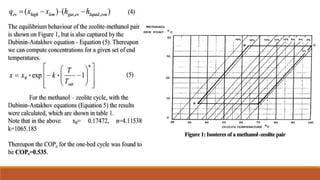

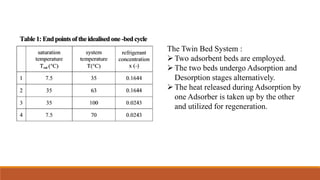

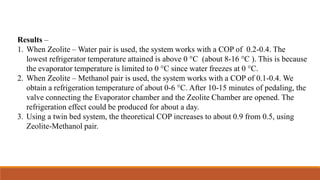

This document describes a pedal-powered refrigeration system based on zeolite adsorption phenomena. The system uses zeolite as the adsorbent and methanol or water as the adsorbate. It consists of two insulated chambers, one containing zeolite and the other containing the adsorbate. A vacuum pump powered by pedaling is used to lower the pressure and induce adsorption and desorption. During adsorption, the adsorbate evaporates in the evaporator chamber, cooling its contents. The vapor is then adsorbed onto the zeolite, releasing heat. This provides cooling without CFC refrigerants and is more environmentally friendly than traditional vapor compression refrigeration.