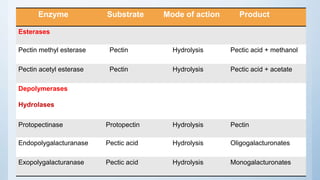

Pectinases are a group of enzymes produced by microorganisms that degrade pectin, used in various industries due to their specificity and low toxicity. They can be produced through submerged or solid-state fermentation, with solid-state offering cost-effective and sustainable advantages. Applications of pectinases include clarifying fruit juices, enhancing wine, and various processes in the paper, textile, and agricultural industries.