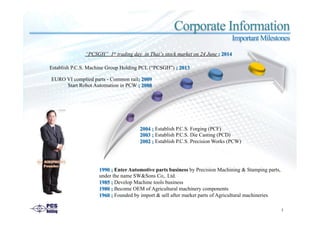

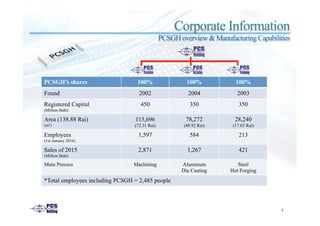

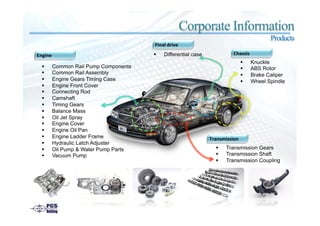

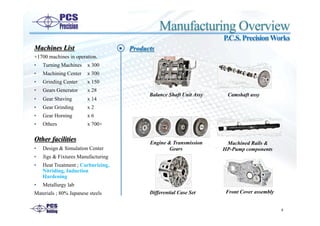

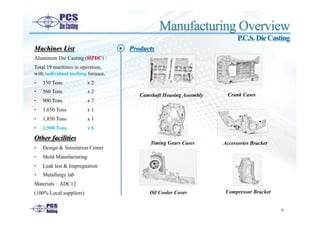

The document provides an overview of P.C.S. Machine Group Holding PCL (PCSGH), a manufacturer of automotive parts and components established in 1960, including key milestones, manufacturing capabilities across precision machining, die casting, and forging facilities, and their core competencies in one-stop engineering and manufacturing services. PCSGH has over 2,400 employees across 3 manufacturing plants and produces a wide range of automotive parts for engines, chassis, transmission, and differentials for customers in the automotive industry.