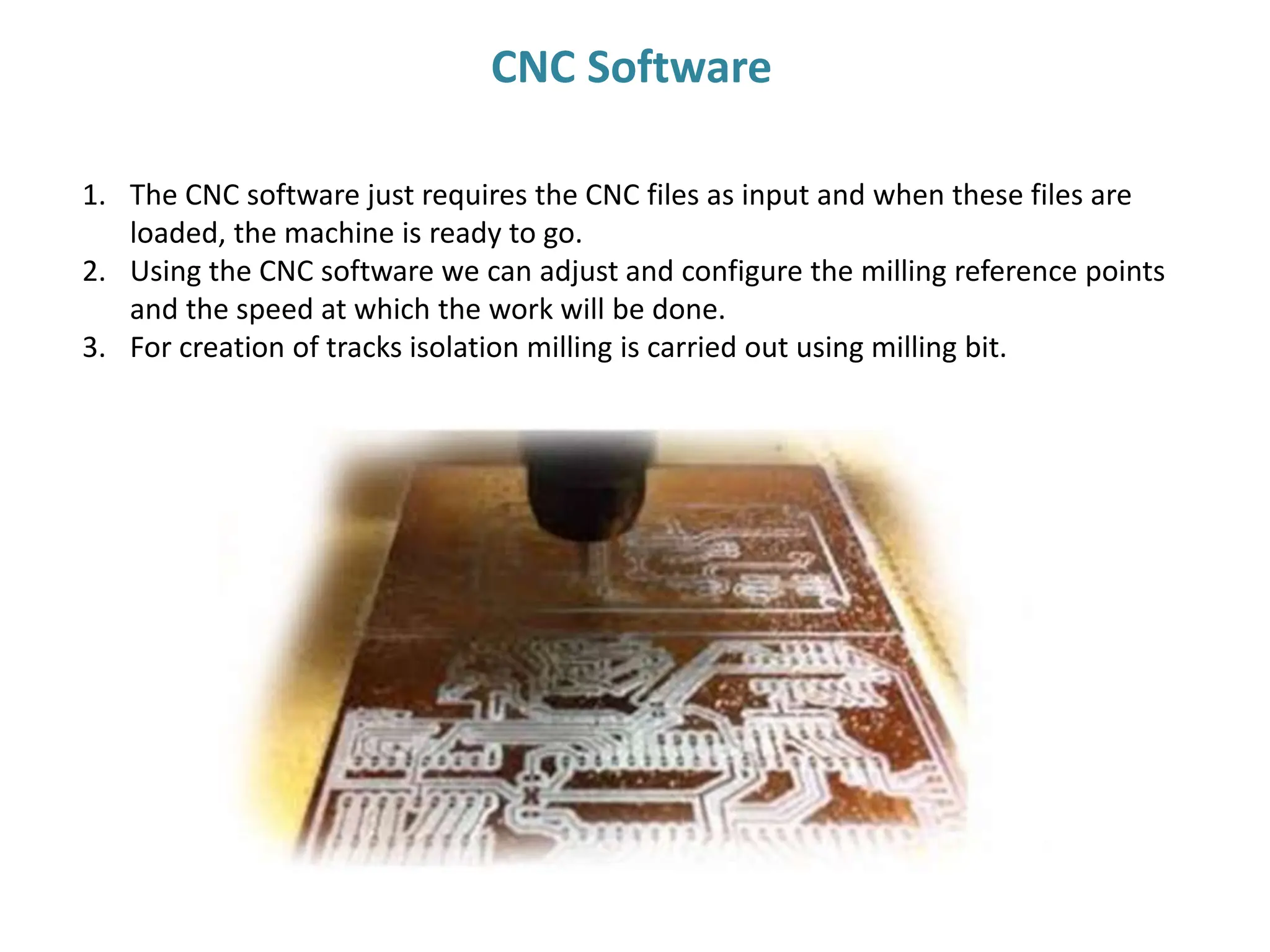

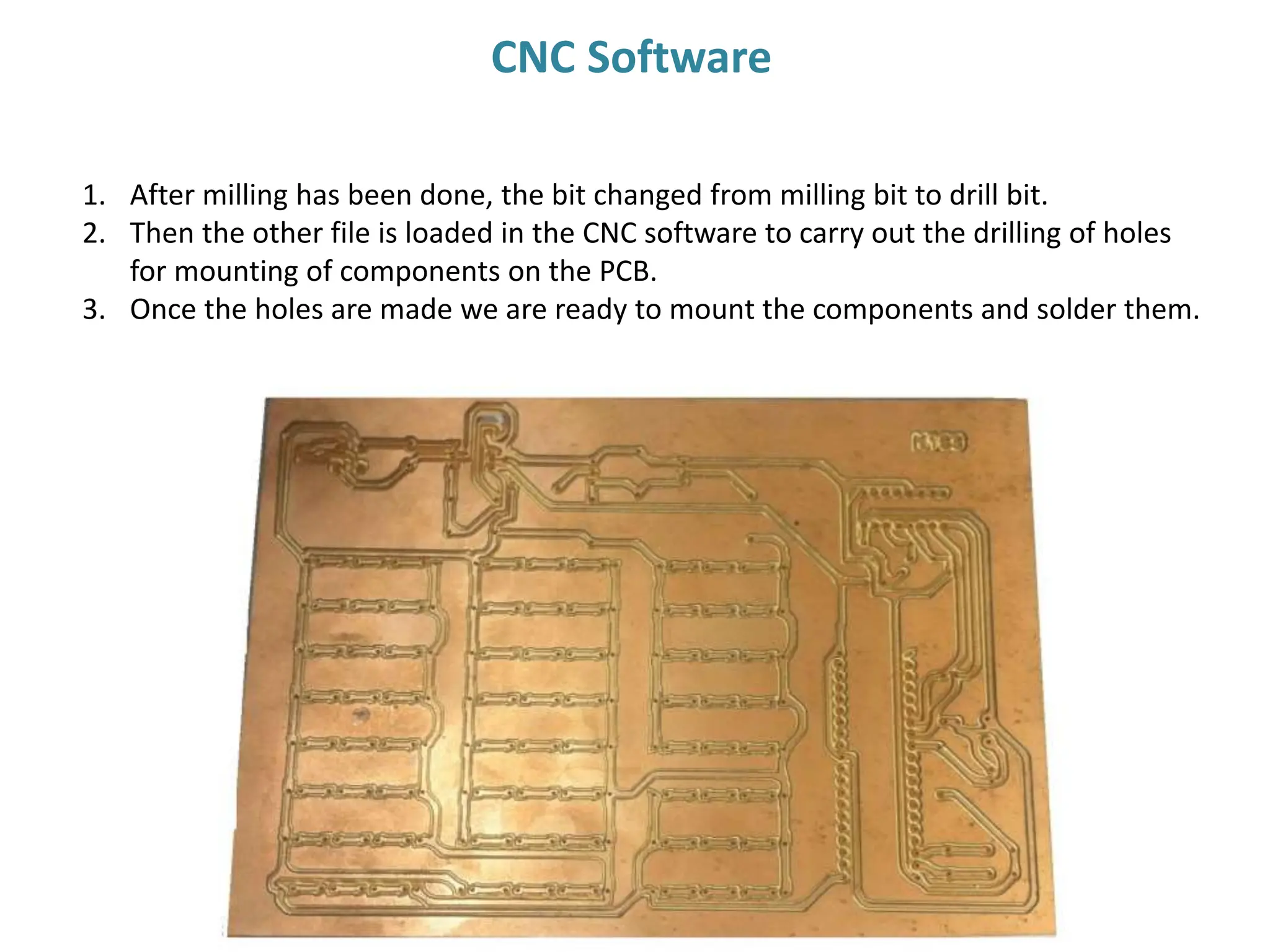

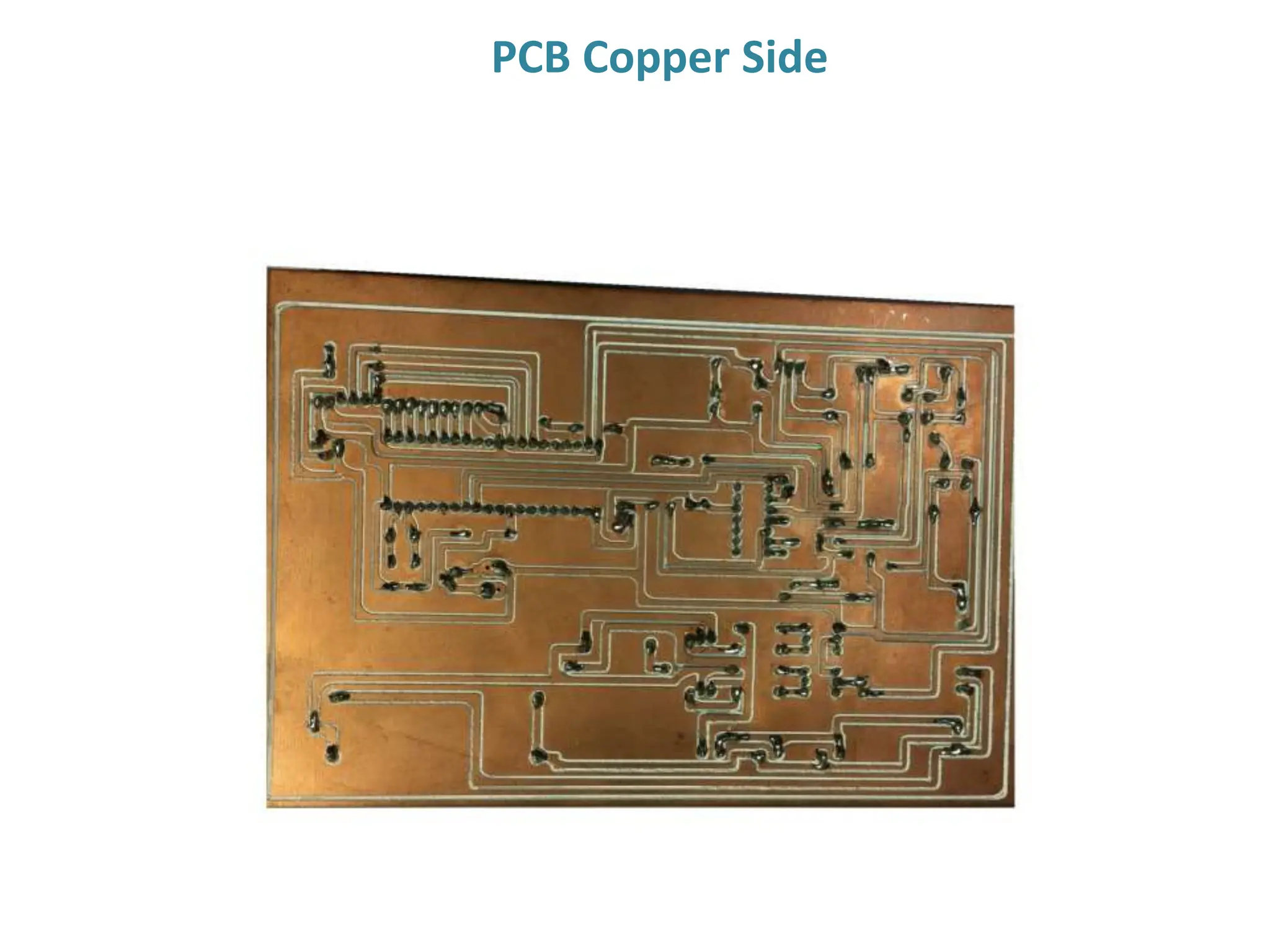

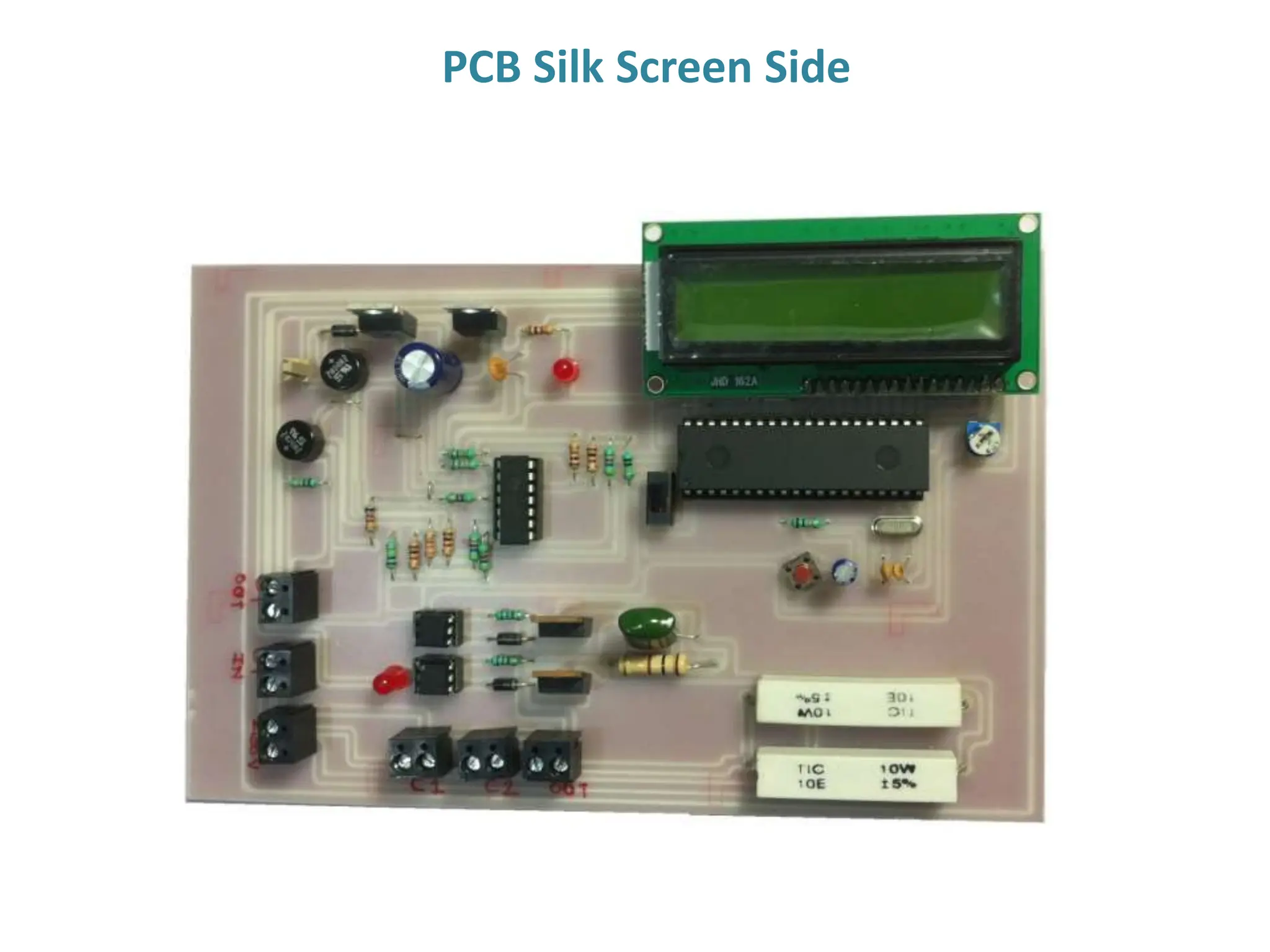

A printed circuit board holds electronic components together and provides electrical connections between them. It has a copper layer that forms the electrical pathways and a fiberglass layer that provides mechanical strength. Components can be mounted on the surface or inserted through holes. Traditionally, etching liquid was used to remove copper from PCBs but this is a slow, inaccurate, and environmentally harmful process. Now, CNC milling is used which is faster, more accurate, and eco-friendly as it requires no chemicals. The PCB design process involves creating files, converting them for CNC use, milling isolation paths, drilling holes, mounting components, and soldering connections.