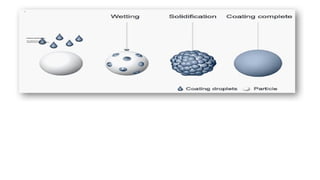

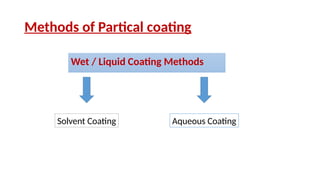

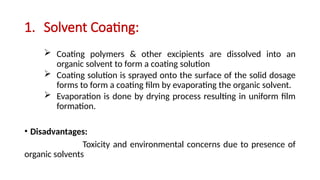

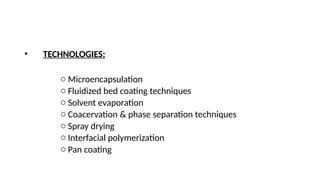

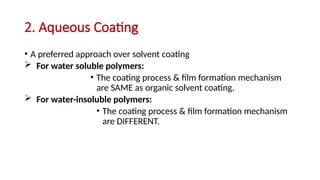

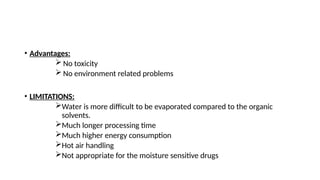

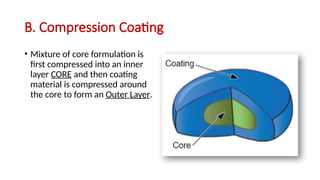

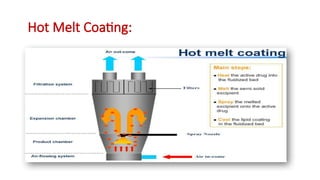

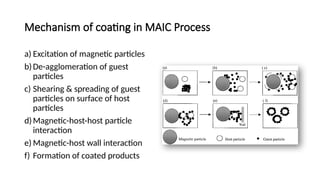

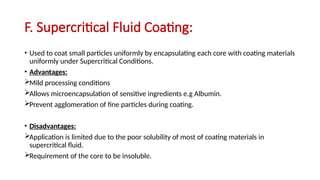

Particle coating involves applying a thin layer around core particles to enhance their properties and functionalities. Various methods such as solvent coating, aqueous coating, and solvent-less techniques like photocurable and hot-melt coating are utilized, each with specific advantages and disadvantages. The goal of these methods is to improve flowability, protect sensitive substances, and control the release of active pharmaceutical ingredients.