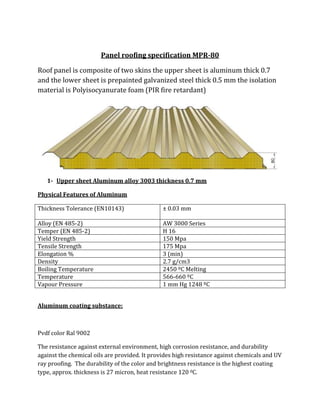

The document summarizes the specifications for an MPR-80 panel roofing system with the following key points:

1. It has an upper sheet of 0.7mm thick aluminum alloy 3003 and a lower sheet of 0.5mm thick prepainted galvanized steel.

2. Polyisocyanurate foam with a density of 40kg/m3 is used as the insulating core material between the two skins.

3. Various stainless steel screws ranging from 5.5mm diameter and 67mm length to 5.5mm diameter and 127mm length are used to fasten the sandwich panels to the supporting structure.