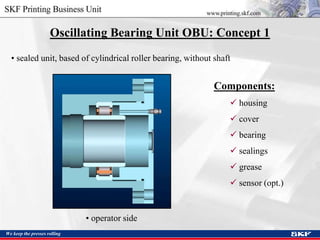

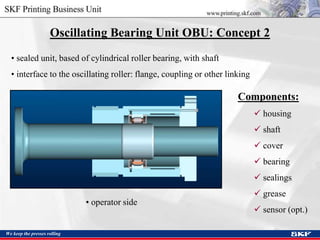

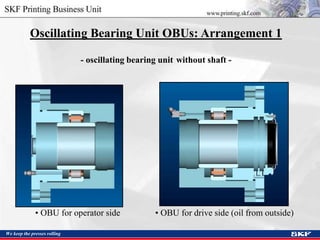

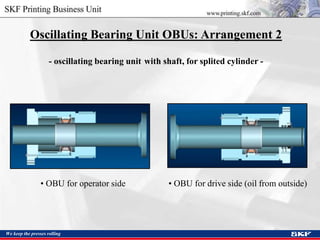

This document discusses oscillating bearing units (OBUs) that are used in printing presses. It proposes using sealed units that contain cylindrical roller bearings, housings, seals, and long-term grease lubrication. This provides advantages like long relubrication intervals, reduced leakage, and making the presses "oil-free". Diagrams show two concepts for the OBUs: with or without a shaft. Arrangement 3 with an external oscillator is recommended for ease of handling and integration into the printing press assembly process.

![We keep the presses rolling

Oscillating bearing: Recommended Product Range

30.10.03

1) = permissible axial displacement from normal position

- oscillating bearings have normally a polyamidcage, except BC1-0628

- the standard radial clearance is bigger than normal (C3)

- oil and grease lubrication are possible

- other sizes then in the table above on request

Designation d

[mm]

D

[mm]

CAR

[mm]

B

[mm]

C

[kN]

C0

[kN]

s1

[mm]

BC1-0160 17 40 16 57,5 23,8 21,6 22

BC1-0628 40 68 15 71 25,1 26 30

BC1-0216 45 75 16 42 44,6 52 12,5

BC1-0190 45 75 21 50 44,6 52 17,5

BC1-0043 55 100 21 45 84,2 95 13

BC1-0454 55 100 21 54 84,2 95 17,5

BC1-0318 55 100 21 59 84,2 95 20](https://image.slidesharecdn.com/oscillatingbearingunitforinkinganddampeningrollers-200804075830/85/Oscillating-bearing-unit-for-inking-and-dampening-rollers-3-320.jpg)

![We keep the presses rolling

Oscillating Bearing Unit OBUs: Arrangement 3

• OBU for operator side • OBU for drive side• [splited cylinder] • external

oscillator

• oscillating bearing unit with shaft

• drive (external oscillator)

• [splited cylinder]

Advantages of arrangement 3:

easy handling of interfaces

all parts out of one hand

easily inclusion in whole process (samples/tests/series)](https://image.slidesharecdn.com/oscillatingbearingunitforinkinganddampeningrollers-200804075830/85/Oscillating-bearing-unit-for-inking-and-dampening-rollers-13-320.jpg)