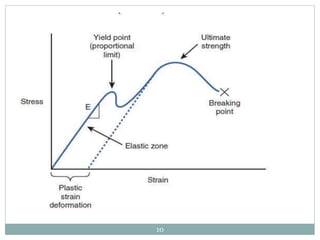

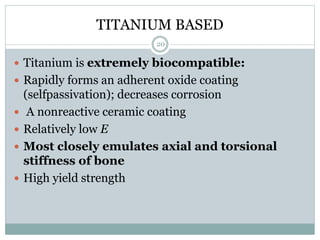

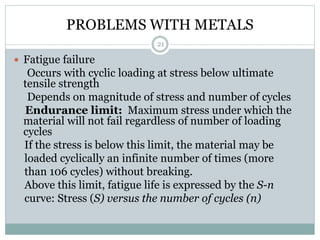

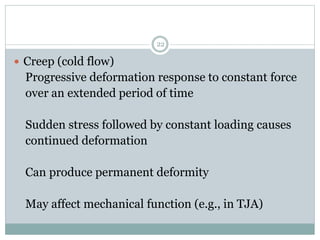

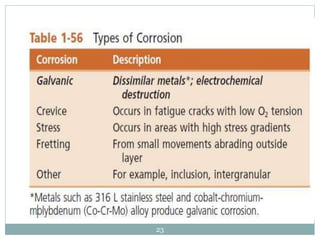

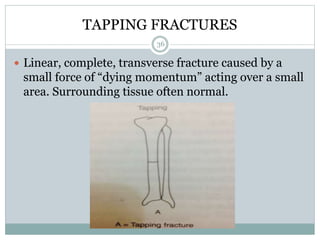

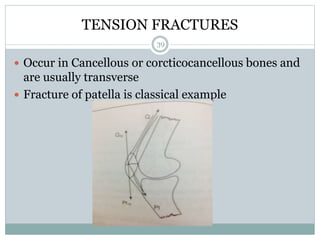

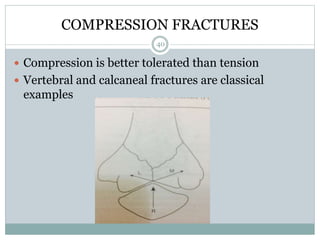

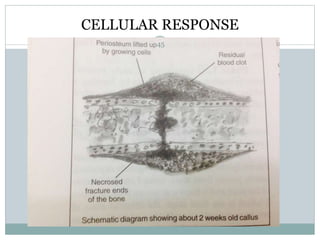

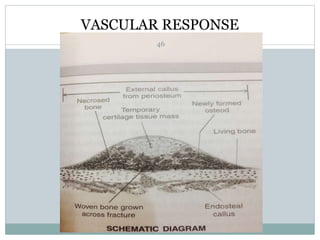

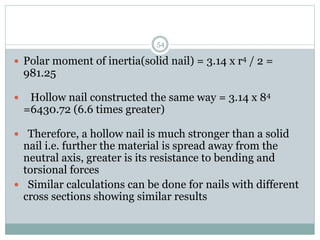

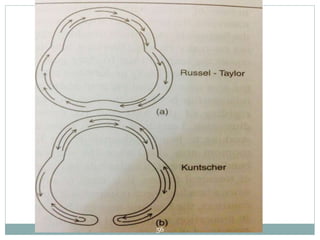

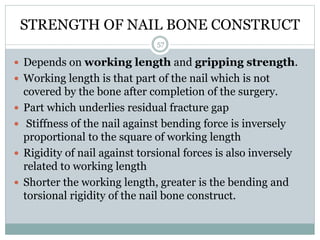

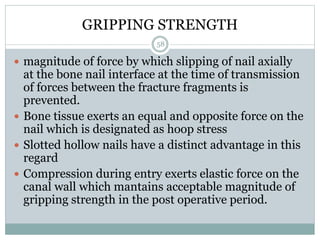

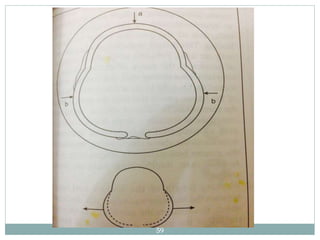

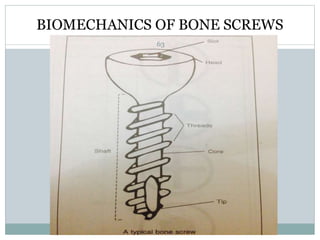

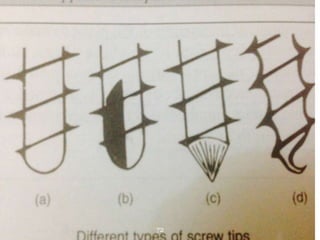

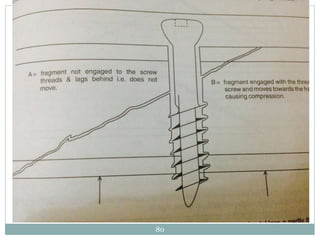

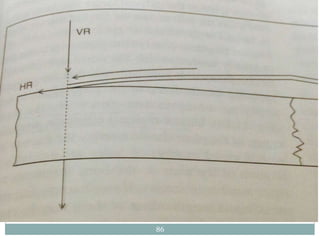

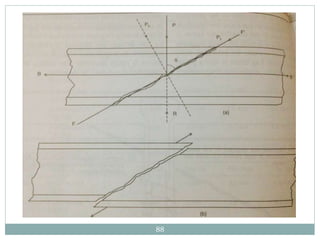

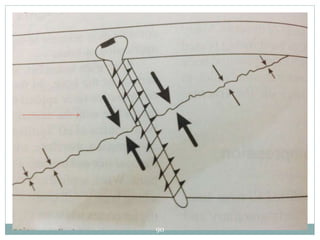

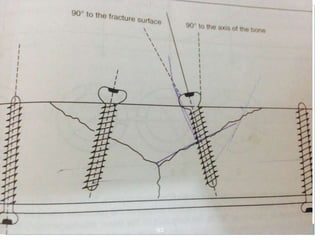

This document provides an overview of biomaterials and applied biomechanics. It defines key concepts like stress, strain, elasticity and plasticity. It describes different types of biomaterials like metals, polymers and ceramics used in orthopedic implants. It also discusses biomechanics of fractures, healing of fractures and biomechanics of implants like intramedullary nails, bone screws and plates. The document covers classification of fractures, phases of fracture healing and factors affecting healing.