Embed presentation

Download to read offline

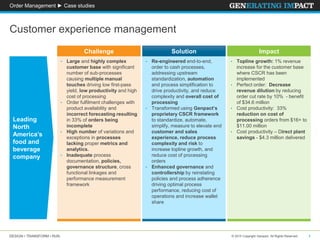

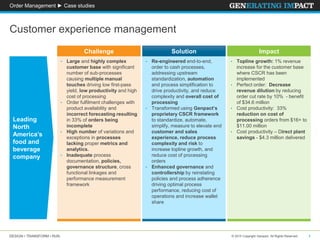

The document outlines a case study on transforming customer experience management for a large North American food and beverage company by re-engineering order to cash processes. It highlights challenges such as low productivity and high processing costs, resulting in a 33% reduction in order processing costs and a 1% revenue increase after implementing Genpact's CSCR framework. Key improvements include enhanced governance, process standardization, and a decrease in revenue dilution by reducing order cut rates.