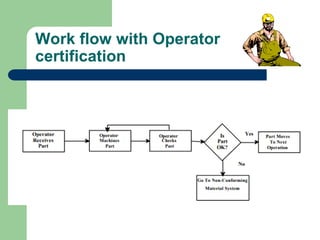

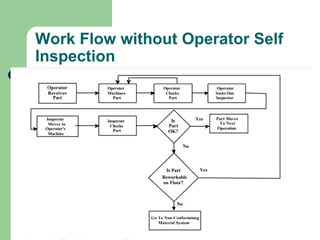

This document discusses operator self-inspection, where production workers are trained to inspect their own work. It provides several benefits over inspection solely by quality personnel, including immediate detection of errors and greater incentive for operators to accurately identify issues. Implementing operator certification requires training operators and managing the human aspects. Principles for operators include not accepting or producing defective work and addressing any issues. The workflow is described both with and without self-inspection. Mistake proofing, root cause analysis, visual management tools, and discipline are important to maintain quality. An operator self-inspection program and process audit procedure are outlined.

![Operator self Inspection

program

1. Awareness to operator regarding upgrade the responsibility

2. Production supervisors should identify the any gap is observed if

yes remove by Training

3. If necessary help form QA Team

4. Maintenance team should explain the machine start up check

5. QA Team would give a control plan which having product and

process parameters

6. Operator is trained for the product parameters and process

parameters by the production

7. Operator is trained for the NC parts identifications and aware of

the red bin]

8. Operator is awarded for the in process inspection formats how to

filled up by qa](https://image.slidesharecdn.com/operator-selfinspection-230407184643-5d479241/85/operator-self-inspection-pdf-14-320.jpg)